Six Sigma is a QC or quality-control program developed in 1986 by Motorola that focuses cycle-time improvement and the reduction of manufacturing defects to a level of no more than 3.4 defects per million.

Six Sigma has evolved into a business-management technique focused on meeting customer requirements, improving customer retention, and improving and sustaining business products and services. Six Sigma is applicable to all industries.

Six Sigma involves statistical improvements to a business process or manufacturing process. Six Sigma enlists qualitative measurements of success and involves usage of statistics, financial analysis, probability and project management to achieve improved results.

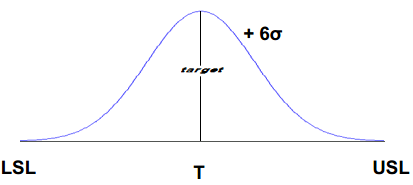

Sigma (σ), is an mathematical symbol representing one standard deviation from the average or mean. Most control charts set their range at +3σ, but Six Sigma extends three more standard deviations. With six sigma, there are only 3.4 parts per million (PPM) defective. A 6 Sigma level process is operating at 99.9997% quality level.

Six Sigma Dimensions

- Six Sigma as a Philosophy – Six Sigma practitioners seek to understand work as a process that can be defined, measured, analyzed, improved and controlled. These processes use inputs (X) to produce outputs (Y). If you can understand how to control the inputs, you will learn how to control the outputs. We use the mathematical equation y = f(x) to express the relationship between inputs and outputs.

- Six Sigma as a Methodology – Six Sigma practitioners typically use the DMAIC (Define, Measure, Analyze, Improve, and Control) methodology to identify and analyze a problem, resulting in the implementation of effective and efficient solutions.

- Six Sigma as a Set of Tools – Six Sigma practitioners use qualitative and quantitative tools to solve tough problems and implement process improvements. Qualitative tools include Voice of the Customer, Brainstorming, and Multi-voting, while the quantitative tools include Control Charts, Value Stream Mapping, and ANOVA.

Six Sigma History

History of six sigma encompassed various events which shaped it’s formation and spread. Six sigma has evolved over time. It’s more than just a quality system like TQM or ISO. The events for six sigma evolution are as

- Carl Frederick Gauss (1777-1855) introduced the concept of the normal curve.

- Walter Shewhart in 1920’s showed that three sigma from the mean is the point where a process requires correction.

- Following the defeat of Japan in World War II, America sent leading experts including Dr. W. Edwards Deming to encourage the nation to rebuild. Leveraging his experience in reducing waste in S. war manufacture, he offered his advice to struggling emerging industries.

- By the mid-1950s, he was a regular visitor to Japan. He taught Japanese businesses to concentrate their attention on processes rather than results; concentrate the efforts of everyone in the organization on continually improving imperfection at every stage of the process. By the 1970s many Japanese organizations had embraced Deming’s advice. Most notable is Toyota which spawned several improvement practices including JIT and TQM.

- Western firms showed little interest until the late 1970s and early 1980s. By then the success of Japanese companies caused other firms to begin to re-examine their own approaches and Kaizen began to emerge in the S.

- Many measurement standards (Zero Defects, etc.) later came on the scene but credit for coining the term “Six Sigma” goes to a Motorola engineer named Bill Smith. (“Six Sigma” is also a registered trademark of Motorola). Bill Smith, along with Mikel Harry from Motorola, had written and codified a research report on the new quality management system that emphasized the interdependence between a product’s performance in the market and the adjustments required at the manufacturing point.

Various models and tools emerged which are

- Kaizen – It refers to any improvement, one-time or continuous, large or small

- TQM – It is Total Quality Management with Organization management of quality consisting of 14 principles

- PDCA Cycle – Edward Deming’s Plan Do Check Act cycle

- Lean Manufacturing – It focuses on the elimination of waste or “muda” and includes tools such as Value Stream Mapping, the Five S’s, Kanban, Poka-Yoke

- JIT– It is Just in Time Business or catering to needs of customer when it occurs.

- Six Sigma – It is designed to improve processes and eliminate defects; includes the DMAIC and DMADV models inspired by PDCA

Quality Pioneers

Various pioneers emerged who helped shape quality principles and laid the foundations for six sigma. They included

Walter A. Shewhart – He is the pioneer of Modern Quality Control who, recognized the need to separate variation into assignable and un-assignable causes. He is the founder of the control chart and originator of the plan-do-check-act cycle. He was the first to successfully integrate statistics, engineering, and economics and defined quality in terms of objective and subjective quality.

Dr. W. Edwards Deming – He studied under Shewhart at Bell Laboratories and major contributions includes developing 14 points on Quality Management, a core concept on implementing total quality management, is a set of management practices to help companies increase their quality and productivity. The 14 points are

- Create constancy of purpose for improving products and services.

- Adopt the new philosophy.

- Cease dependence on inspection to achieve quality.

- End the practice of awarding business on price alone; instead, minimize total cost by working with a single supplier.

- Improve constantly and forever every process for planning, production and service.

- Institute training on the job.

- Adopt and institute leadership.

- Drive out fear.

- Break down barriers between staff areas.

- Eliminate slogans, exhortations and targets for the workforce.

- Eliminate numerical quotas for the workforce and numerical goals for management.

- Remove barriers that rob people of pride of workmanship, and eliminate the annual rating or merit system.

- Institute a vigorous program of education and self-improvement for everyone.

- Put everybody in the company to work accomplishing the transformation.

Joseph Juran – His major contributions are directing most of his work at executives and the field of quality management and developing the “Juran Trilogy” for managing quality, as Quality planning, quality control, and quality improvement. He also enlightened the world on the concept of the “vital few, trivial many” which is the foundation of Pareto charts.

Philip Crosby – He stressed on Quality management and four absolutes of quality including

- Quality is defined by conformance to requirements.

- System for causing quality is prevention not appraisal.

- Performance standards of zero defects not close enough.

- Measurement of quality is the cost of nonconformance.

Arman Feigenbaum – He developed a systems approach to quality (all organizations must be focused on quality) by emphasizing that costs of quality may be separated into costs for prevention, appraisal, and failures (scrap, warranty, etc.)

Kaoru Ishikawa – He developed the concept of true and substitute quality characteristics as

- True characteristics are the customer’s view

- Substitute characteristics are the producer’s view

- Degree of match between true and substitute ultimately determines customer satisfaction

He also advocated of the use of the 7 tools and advanced the use of quality circles or worker quality teams. He also developed the concept of Japanese Total Quality Control

- Quality first and not short term profits.

- Next process is the customer.

- Use facts and data to make presentations.

- Respect for humanity as a management philosophy of full participation

Genichi Taguchi – He developed the quality loss function (deviation from target is a loss to society) and promoted the use of parameter design (application of Design of experiments) or robust engineering. The goal is to develop products and processes that perform on target with smallest variation insensitive to environmental conditions and the focus is on engineering the design.

Meaning of Six Sigma

The term ‘Six Sigma’ is drawn from the statistical discipline ‘process capability studies’. Sigma, represented by the Greek alphabet ‘σ’, stands for standard deviation from the ‘mean’. ‘Six Sigma’ represents six standard deviations from the ‘mean.’ This implies that if a company produces 1,000,000 parts/units, and its processes are at Six Sigma level, less than 3.4 defects only will result. However, if the processes are at three sigma level, the company ends up with as many as 66,807 defects for every 1,000,000 parts/units produced.

The table below shows the number of defects observed for every 1,000,000 parts produced (also referred to as defects per million opportunities or DPMO).

| Sigma Level | Defects per million opportunities |

| Two Sigma | 308,507 DPMO |

| Three Sigma | 66,807 DPMO |

| Four Sigma | 6,210 DPMO |

| Five Sigma | 233 DPMO |

| Six Sigma | 3.4 DPMO |

Process standard deviation (σ) should be so minimal that the process performance should be able to scale up to 12σ within the customer specified limits. So, no matter how widely the process deviates from the target, it must still deliver results that meet the customer requirements. Few terms used are

- USL – It is upper specification limit for a performance standard. Any deviation beyond this is a defect.

- LSL – It is lower specification limit for a performance standard. Any deviation below this is a defect.

- Target – Ideally, this will be the middle point between USL and LSL.

Six Sigma approach is to find out the root causes of the problem, symbolically represented by Y = F(X). Here, Y represents the problem that occurs due to cause (s) X.

| Y | x1, x2, x3, …., xn |

| Dependent | Independent |

| Customer related output | Input-process |

| Effect | Cause |

| Symptom | Problem |

| Monitor | Control |

Continuous Improvement

Continuous improvement involves constantly identifying and eliminating the causes that prevent a system or process from functioning at its optimum level. The concept of continuous improvement originated in Japan in the 1970s. It was adopted in many countries, including U.S.A., in the early 1980s. Continuous improvement—and consequent customer satisfaction—is the principle on which the concept of Lean manufacturing is developed. When this principle is combined with just-in-time technique, it results to Lean manufacturing. Continuous improvement helps an organization to add value to its products and services by reducing defects, mistakes, etc. and to maximize its potential. As continuous improvement requires constant ongoing efforts, it is essential that the top management takes a long term view and commits itself for its implementation.

Transfer Function

The transfer function is Y=f(X). To understand the link between the transfer function and Six Sigma, you can begin with understanding what Y is. If you consider a complete process as inputs flowing into a transformation of sorts, which produces an output, then Y is the output or the result. Y can also be considered as the actual process that you want to improve.

In the function, X is the variables that actually contribute to the success of the process, or the inputs. The f, or function of X, gives you the Y result that you’re looking for. So another way of thinking about this is the X inputs go through the f function of transformation to generate the outputs or the Y value that you’re looking for.