A Definition of Warehouse Optimization

Warehouse optimization is key to the efficient operation of warehouses of all sizes. A disciplined process, warehouse optimization includes automation and a determination of how to save time, space, and resources while reducing errors and improving flexibility, communication, management, and customer satisfaction. Other warehouse optimization considerations include warehouse flow, product placement, storage, and retrieval systems. Warehouse optimization is vital to lean warehouses and agile supply chains. The most efficient warehouses are those that have been optimized to beat the competition on every level.

Warehouse Optimization Challenges

Most of the challenges that arise in warehouse optimization are related to errors, inefficiency, and lack of transparency. Many warehouse managers correct these challenges with warehouse management systems, automated material handling systems, barcoding, and automated data collection.

As Apptricity CEO Tim Garcia notes, there are five common warehouse problems that pose challenges to warehouse optimization: inventory accuracy, inventory location, space utilization and warehouse layout, redundant processes, and picking optimization.

- Inventory accuracy – Companies often do not know what they have in stock and have too little visibility into their warehouses when they lack an automated system

- Inventory location – Without accurate insight into inventory location, pickers cannot work efficiently, which results in slower loading processes and backups in dock scheduling

- Space utilization and warehouse layout – If storage systems and warehouse racking is not optimized, space required to house inventory and labor needed inside the warehouse increase

- Redundant processes – Redundant processes and multiple touches hurt a company’s bottom line and are inefficient

- Picking optimization – Too many warehouses lack common routes for picking items for shipment because their manual processes are inefficient

Warehouse Optimization Techniques and Best Practices

When optimizing warehouse operations, automation is key. The more you automate picking, packing, and shipping processes, the fewer human touches are required for products and orders. Automation via warehouse management systems and warehouse control systems makes it possible to manage materials handling equipment in real time and clues in warehouse managers to possible bottlenecks. It’s also important to automate warehouse operations because doing so allows for data collection to occur more quickly, efficiently, and accurately; improved data collection equates to real-time data and intelligence for warehouse managers.

Warehouse optimization also includes achieving the best warehouse layout design to optimize warehousing functions and to utilize space as efficiently as possible. In order to do this, warehouse managers should carefully analyze their data on reserve storage, forward pick, cross docking, shipping, receiving, assembly and special handling lines, and quality and inspection areas in addition to receiving, shipping, and inventory levels. Keep in mind that warehouse layout should take product storage, inbound and outbound operations, and value-added processes into consideration.

But, you should not get so caught up in automation and warehouse layout design for warehouse optimization that you fail to account for other things that significantly impact warehouse operations. Inventory management and warehouse operations consultant and practitioner Dave Piasecki reminds warehouse managers that there are little things that can dramatically affect their warehouses, too, and accounting for them improves warehouse optimization. Specifically, Piasecki points to training, tools, low-cost equipment, equipment maintenance, cooling, housekeeping, identification, forms and paperwork, and managing miscellaneous storage as the little things that can make or break warehouse optimization.

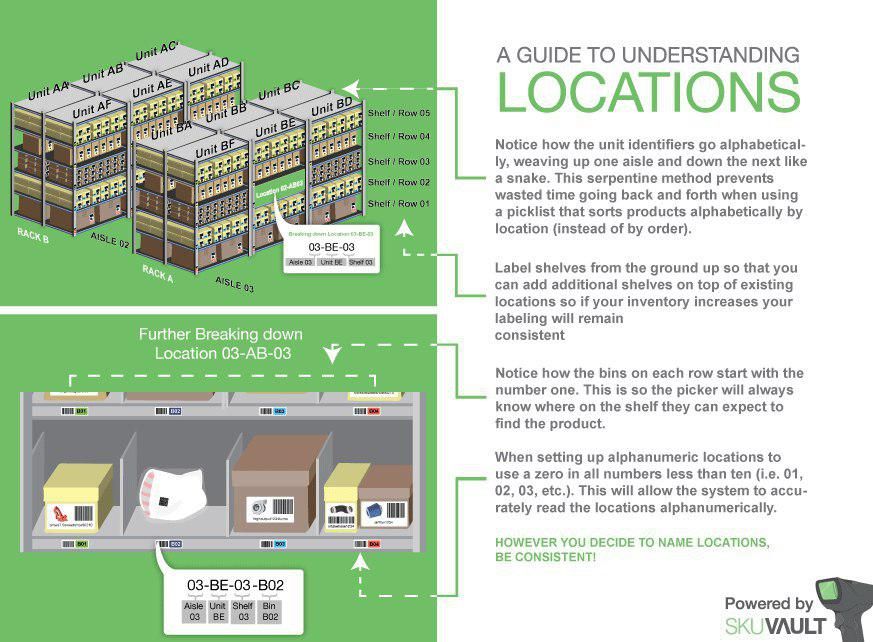

No matter which avenue of warehouse optimization you choose to pursue first, identification must play a role in your process. For example, clear product and location identification are critical to picking and putaway efficiency and accuracy. Identification of storage areas and staging lanes is another must. Warehouses that are winning at optimization opt for easily read labels on pallets, cartons, storage shelving, pallet racks, and aisles and floors. The best options for warehouse labels include durable floor label systems, barcode rack labels, long-range reflective barcode labels, and pallet barcode labels.

Tips to better organize your warehouse layout:

- Measure the space you have to work with.

- Define storage, sorting, shipping, office, and product locations.

- Pick the best shelving for your products e.g. two-tier, fixed, mobile, etc.

- Create clear labeling for aisles and product locations.

- Establish optimal material flow paths and picking paths.

- Place hottest selling items in close, easy to reach locations.

- Avoid overstocking items that are slow sellers to open more product space.

Warehouse Safety

A major component to managing a warehouse is to ensure the safety of your staff. The constant moving of people and products can create the perfect environment for accidents to occur. Therefore, you should make sure aisles and walkways are clean and free of spills and debris at all times.

Provide Cleaning Tools

As the owner of a company, it’s not exactly your top priority to keep tabs on the cleanliness of your warehouse. Instead, hold supervisors and staff accountable for their work environment. Have brooms, mops, and trash cans readily available and encourage employees to take care of their workstations throughout the day.

Install Proper Lighting

Make sure all areas are lit properly. Low visibility can lead to mishaps during picking and sorting. Bright lights encourage alertness and safety by keeping your employees awake and aware of their surroundings. Lastly, provide large visual cues throughout your warehouse of various safety and overall warehouse guides to create a consensus on how the workplace operates.

Consistent Inspections

Conduct visual inspections of your warehouse regularly to ensure that you are always at peak efficiency. Clean, neat, and organized are words that should be synonymous with your warehouse.

Establish and Optimize Processes

As a business owner or warehouse manager, your primary goal is to ensure that the right product gets to the right place at the right time. In a way, you are the gatekeeper between the business and the customer. As the gatekeeper, it’s your job to facilitate this transition and make the process appear as seamless as possible, which, as you may already know, is no easy task.

In order to achieve this, your entire warehouse operation from receiving, to picking, to shipping, to data collection needs to be optimized for peak efficiency.

Receiving

You should think about the optimization of your warehouse workflow the moment a product arrives in the receiving bay. When that product order arrives, it’s officially a part of your warehouse. Once received, products are checked for damages, mis-picks, and quantity. It’s important to give employees plenty of space to remove inventory from pallets and perform other duties.

There are two common methods for receiving products: manual and automated.

In the manual checking process, an employee looks over a shipping invoice and visually checks that everything listed has arrived and has the right quantity. While this method is one of the cheaper options for checking products, it increases the chance of human error dramatically. During manual checks, it’s not uncommon for people to look over a certain item or mistake one product for another. In many cases, multiple people are required in order to double-check the shipment. This requires twice the effort and costs your business time and money.

Instead, try to automate this process with some form of inventory management software or warehouse management software. Yes, they are different. Do your research and decide which one will work best for your warehouse. Automation minimizes the error of manual checking by doing the work for you. Instead of visually cross referencing an invoice with the product, automation methods use scanners to run a comparison by simply scanning product barcodes while unloading them. When optimizing your warehouse always remember to work smarter not harder.

Picking

Picking is one of the most pivotal processes in your warehouse. When done efficiently, you have a well-running operation. When a product is picked incorrectly, you appear less reputable as a company, and to make matters worse you just wasted the time and money it took to pick and ship that product and now have to spend more time picking and sending the right product.

To optimize this process and avoid picking nightmares consider the following:

- Don’t mix multiple SKUs in the same location

- Place products in optimal locations for pickers

- Designate zones for certain products e.g. peak season products, on sale items, or hot sellers

- Pick as many orders as possible in a single run to lower pickers travel time

- Automate picking process, like alphabetizing the locations of your products

- Implement incentives for pickers

Picking actually has optimization opportunities that many warehouse managers tend to overlook.

Study the habits of your buyers. By doing so you can find new ways to optimize picking. For example, if your company sells sports equipment and you have a larger number of retail buyers who purchase from you regularly, consider how you are picking for these customers. Instead of picking the orders as they arise, try picking them all at once. If you have multiple buyers who make the same purchases regularly, go ahead and prep for these orders and sort them according to past purchases.

You can also use picking to learn about your products. By keeping track of how frequent an item is picked you can make in-depth decisions about that product.

For example, say that you stock a product that needs to be picked only once every few weeks. You should stop wasting inventory space on low selling items and think about how to optimize these products.

Packing

Packing needs to be done quickly with minimal mistakes. Packaging hundreds of orders a day can be a real nuisance without structured methods. Start by establishing a packing location that is near the shipping location. From there you want to ensure that the physical method of packing is optimal.

Even the way you package products contributes to the overall efficiency of your warehouse. Designate only two or three standard shipping packages. With only two or three boxes to choose from, pickers are able to assemble orders at a faster rate. This approach also optimizes freight expenses and makes it easier to support a pick-path methodology.

Shipping software also increases the efficiency of the packing process. Shipping software can create product labels and calculate the weight of the package. They also often integrate with warehouse management systems to make the process more seamless. However, these features are just the tip of the iceberg. Learn what shipping software can do for you inventory here.

Shipping Time

Diversified shipping options gives your customers more orders delivered on time. If you are currently only using one shipping solution, do your research and see what other shipping providers are available to you. Shipping providers like FedEx, UPS, USPS, and freight on board (FOB) are some of the most popular methods to choose from. Understand that the more shipping providers you have, the more options you have if trouble arises.

For example, imagine that it’s holiday season and you have late orders that need to be delivered as fast as possible. If you only use one shipping provider and they are not able to deliver the product then you are out of a sale. However, with multiple shipping providers your chances of making the delivery increases.

Increasing shipping efficiencies can also open doors for your business. Say for instance you are a warehouse who wants to gain access to Amazon consumers using Amazon Prime. Most sellers can only become a Prime member through Fulfillment by Amazon (FBA), which ensures two-day shipping.

There’s also Merchant Fulfilled Prime. This method allows merchants who meet certain shipping standards to fulfill shipping themselves, ultimately saving the merchants the overhead cost associated with FBA. But the main requirement is that you must consistently ship quickly and efficiently. To be competitive, faster is always better.

Keep a list of multiple shipping methods and stay up-to-date on changes in the shipping industry. Also remember to track orders to ensure delivery in a way that works with your business model.

Data Collection

The purpose of data collection is to allow warehouse managers to see what they are doing well and what areas still need improvement. This information will give users an aggregate breakdown of everything in the warehouse. Having real actionable data grants managers the ability to make informed decisions about their products and processes. Which, when used correctly, can clearly point out any fallacies in the warehouse that need to be optimized.

If you see people doing a ton of writing and typing on keyboards as a means to collect data, you have a problem. With the almost endless methods for data collection, you should not be relying on manual collection methods. These methods can be flawed and skew data to the point that the information collected becomes useless.

Instead, use mobile computers with barcode scanners to collect data as a more reliable solution. Mobile computer and barcode scanners are the tools you will need to automate much of your warehouse process. When used, they collect important data about every process in the warehouse. This data includes, but is not limited to:

- purchase orders

- replenishment needs

- product locations

- picking orders

- purchase history, and so much more.

Tools and Software

To keep a competitive edge in any industry you have to be able to adapt and meet the expectations of your consumers. The same is true for warehouse managers. In an era of technological growth, you’ll want to be in the know to avoid falling behind. Research what tools and software are currently driving the industry and strive to adopt the tools and tech that will propel your business.

Barcode scanners, minicomputers, iPads, and radio-frequency identification (RFID) – the electromagnetic fields to automatically identify and track tags attached to objects – are a few examples of warehouse data collection tools. Each can be used to coordinate warehouse processes and improve efficiency.

However, like any tool, they are only useful when used appropriately. Keep in mind the goal is to automate your workflow, and tools like these are the physical pieces that link all the parts of your warehouse. If a tool or software is out-of-date or used incorrectly, every step in your workflow will be incorrect from the top-down.

Automation

At this point you’ve seen the term automation enough, but what exactly does it mean to automate? Automation refers to the software and tools used to sync the various departments in a warehouse while coordinating data into a single platform. It can also be used to describe the use of tools to relieve manual processes.

Warehouses use different software in different departments to operate. Every department has its own software needs, and warehouse management software is the hub used to sync and manage the various tools and software.

For example, a warehouse may use a shipping software like ShipStation to manage orders and ChannelAdvisor to sync online sales and shipping needs. A warehouse management software, like SkuVault, comes in and collects the information to show managers exactly how much product is available in the warehouse and online as well as what products have been shipped or still need to be shipped.