Warehouse Management System (WMS)

Let’s learn more about Warehouse Management System (WMS). Warehouse is a place where goods or merchandise are stored, like a storehouse. Stored goods can include any raw materials, components, or finished goods associated with agriculture, manufacturing, or commerce. Loading docks are used to load and unload goods while forklifts and cranes are used for moving goods.

Some of the most common warehouse storage systems are described below.

- Pallet racking is a material handling storage aid system designed to store materials on pallets, this may include drive-in, drive-thru, double deep, pushback, and gravity flow.

- Mezzanine is a partial story between two main stories of a building including structural, roll formed, rack supported, and shelf supported

- Cantilever Rack including structural and roll formed. It is a projecting structure, such as a beam, that is supported at one end and carries a load at the other end or along its length.

- Industrial Shelving including metal, steel, wire, and catwalk

- Automated Storage and Retrieval System (ASRS) including vertical carousels, vertical lift modules, horizontal carousels, robotics, mini loads, and compact 3D

With the introduction of Just In Time technique or JIT, the use of traditional storage warehouses has declined. JIT offers a much reduced processing of inventories by way of delivering directly the products and commodities to retailers. This is similar with automobile industries wherein the parts are directly delivered to the assembly plants. However, due to the offshore outsourcing, the distance between manufacturers and retailers is of another major concern. This demands at least one warehouse in every country or region of operation in order to cater to the expansion of the business.

The recent development of storage warehouses presents double purpose. Storage warehouses can now be manipulated as retail stores. The traditional high ceilings with decorative shelves are replaced with sturdy industrial racks. These racks hold ready to sell items placed just below the racks while merchandises which are in pallets are usually stored on top of the shelves. In this way, one building can be used as warehouse and at the same time offers retailing that can save a lot of resources compared to having two separate buildings for each purpose.

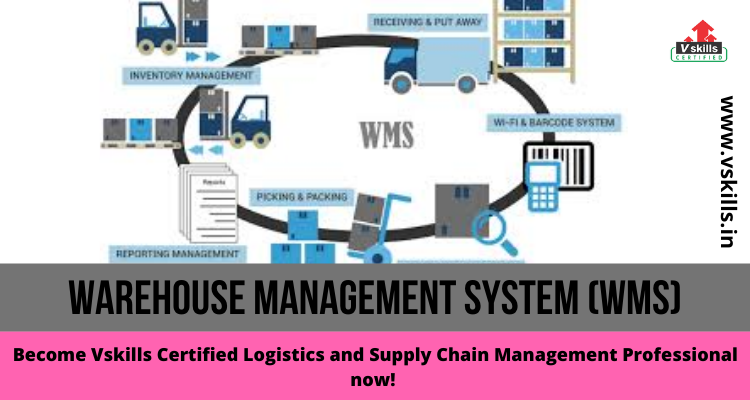

WMS

A warehouse management system, or WMS, is an essential part of the supply chain and mainly aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, put-away and picking. The systems also direct and optimize stock put-away based on real-time information about the status of bin utilization.

Warehouse management systems often employ Auto ID Data Capture (AIDC) technology, such as barcode scanners, mobile computers, wireless LANs and potentially Radio-frequency identification (RFID) to efficiently monitor the flow of products. Once data has been collected, there is either batch synchronization with, or a real-time wireless transmission to a central database. The database can then provide useful reports about the status of goods in the warehouse.

Objective of Warehouse Management System

The primary objective of a warehouse management system is to provide a set of computerized procedures to handle the receipt of stock and returns into a warehouse facility, model and manage the logical representation of the physical storage facilities such as racking etc, manage the stock within the facility and enable a seamless link to order processing and logistics management in order to pick, pack and ship product out of the facility.

Warehouse management systems can be stand-alone systems or modules of an ERP system or supply chain execution suite. The purpose of a WMS is to control the movement and storage of materials within a warehouse which might be described as the legs at the end-of-the line which automates the store, traffic and shipping management.

The warehouse management system helps in tracking data products during the production process and act as an interpreter and message buffer between existing ERP and WMS systems. Warehouse Management is not just managing within the boundaries of a warehouse, but is much wider and goes beyond the physical boundaries. Inventory management, inventory planning, cost management, IT applications & communication technology to be used are all related to warehouse management. The container storage, loading and unloading are also covered by warehouse management today. Even production management is to a great extent dependent on warehouse management.

Efficient warehouse management gives a cutting edge to a retail chain distribution company. Warehouse management does not just start with receipt of material but it actually starts with actual initial planning when container design is made for a product. Warehouse design and process design within the warehouse such as Wave Picking is also part of warehouse management. Warehouse management is part of Logistics and SCM. Warehouse Management monitors the progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations.

Warehouse management deals with receipt, storage and movement of goods, normally finished goods, to intermediate storage locations or to final customer. In the multi-echelon model for distribution, there are levels of warehouses, starting with the Central Warehouse(s), regional warehouses services by the central warehouses and retail warehouses at the third level services by the regional warehouses and so on.

The objective of warehousing management is to help in optimal cost of timely order fulfillment by managing the resources economically. Warehouse management is basically management of storage of products and services rendered on the products within the four walls of a warehouse.