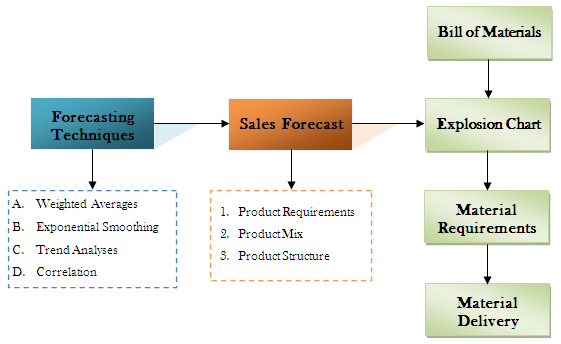

The prime tool or technique of material planning is the Bill of Material Explosion, illustrated below:

Figure 1: Material Planning

Material planning is based on the demand planned for end products. Forecasting tools, such as weighted average method, time series method and exponential smoothing are some of the widely known methods used for material planning. Upon demand forecasting, the material planning activity is pursued. Bill of Materials is the document that details the requirement for a list of materials, unit consumption and code numbers for each product location. Explosion Chart is a chain of bills of materials clustered in a matrix, such that the combined requirements for varied components can be met. Materials requirement can be derived from demand forecast through explosion charts using bill of materials. Therefore, MRP leads to the development of delivery schedule of materials and hence, the purchase of those material requirements.