Methods of Taguchi

Taguchi methods stress that companies should focus their quality efforts on the design stage. In addition, it is much cheaper and easier to make changes during the product design stage than later during the production process.

- Moreover, using Taguchi methods for applying concepts like the design of an experiment to product design. And, this method is an engineering approach that is on the basis of developing a robust design.

- Above all, Taguchi has also had a large impact on today’s view of the costs of quality. And, the traditional view of costs of conformance to specifications is incorrect, and that brought a different way to look at these costs.

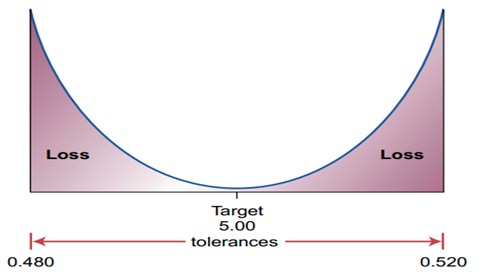

For example, recall that conformance to specification specifies a target value for the product with tolerances, say 5.00 +/- 0.20. According to the traditional view of conformance to specifications, losses in terms of cost occur if the product dimensions fall outside of the specified limits. For this, see the below figure,

Dr.Taguchi Assumptions

- Dr. Taguchi said from the customer’s view that there is little difference whether a product falls just outside or just inside the control limits.

- However, by pointing out that there is a much greater difference in the quality of the product between making the target and being near the control limit.

- And, on the basis of this, he defines the following: as conformance values move away from the target, loss increases as a quadratic function. This is the Taguchi loss function. See the below figure for this,

Taguchi-Three step Approaches

For assigning nominal values and tolerances for product and process parameters there are three approaches,

- System design – the application of scientific engineering and technical knowledge to produce a basic functional prototype design.

- Parameter design – the identification of the settings of product or process parameters that reduce the sensitivity of the designs to sources of variation.

- Tolerance design – the determination of tolerances around the nominal settings identified by parameter design.

Classification of the variables that affect the performance

- This is divided into two categories:

- Firstly, design parameters.

- Secondly, sources of ‘noise’.

Moreover, the sources of noise are all the variables that cause the performance characteristics to deviate from the target values. And, the key noise factors are those that represent the major sources of variability. And, these should be identified and included in the experiments to design the parameters. Above all, this is done by systematically varying the design parameter settings and comparing the effect of the noise factors for each experimental run.

Learn and enhance your knowledge about Taguchi methods. Become a Certified TQM Professional Now!