Before deciding on the location of a store, you would first like to understand the need, whether it is for one store or many stores, the reporting pattern to which department – manufacturing or materials department, the transport facilities to be used, the need for future expansion, and the need and types of materials to be used in the organization.

Nevertheless, following principles serve as guidelines for stores location:

- Stores should aim at maximising service to user departments at an optimum overall cost.

- Minimal material handling and transportation costs should be prioritized.

- In-built flexibility should be accommodated to meet future requirements.

- Proper communication linkages should be in place.

- Adequate safety measures should be made available.

- The type and quantity of materials should be decided beforehand.

- The number of end users and vendors should be taken into account.

- Economy and efficiency are the key determinants for proper stores layout.

- An underutilized warehouse indicates capital wastage, including time and labour.

- The objective should be based on ascertaining a continual, uninterrupted workflow across the stores such that there are smooth operations and optimal services in place.

- The store space utilisation should be decided basis material handling and maximum speed of movement.

- The items should be traceable easily with less of efforts and expenditure.

- Develop adequate lighting, colour schemes and ventilation.

- Safety appliances, such as aprons, hand gloves, goggles, etc. should be readily accessible.

- Ensure the stores department refrains from unauthorized access.

A retail store layout (whether physical or digital) is the strategic use of space to influence the customer experience. The interior retail store layout has two important components:

- Store Design: The use of strategic floor plans and space management, including furniture, displays, fixtures, lighting, and signage. Website designers and user experience (UX) researchers use space management techniques and web design principles to optimize e-commerce websites. We’ll further discuss a variety of popular retail floor plans later in this article.

- Customer Flow: This is the pattern of behavior and way that a customer navigates through a store. Understanding customer flow and the common patterns that emerge when customers interact with merchandise based on the store layout is critical to retail management strategy. Physical retailers are able to track this using analytics software and data from in-store video and the Wi-Fi signal from smartphones.

While the exterior retail store layout includes exterior store design and customer flow, it also includes the following factors:

- Geographic location of the retail store (real estate)

- Size of the building and length of the walkways accessible from the entrance and exit

- Use of furniture and exterior space for people to gather and interact

- Style of architecture of the retail building

- Color of paint and choice of exterior building materials

- Design of the physical entrance and exterior window displays

Store Floor Plan

A good retail store layout starts on paper, where you work out building specs, customer traffic flow, product placement, and more, before ever installing a single display. Thoughtful planning lets you explore options and create a store layout that encourages customers to browse and buy.

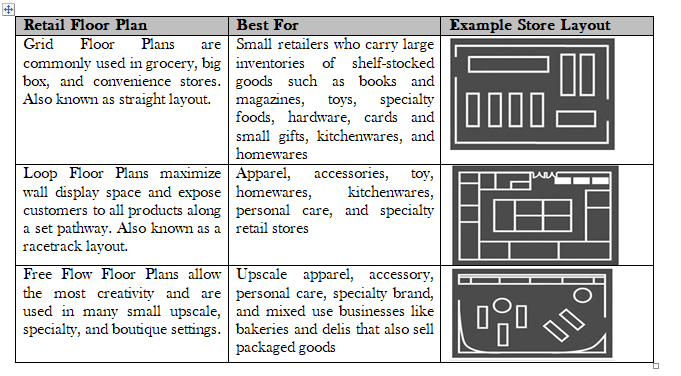

Large or small, most retail stores use one of three basic types of retail store layouts. Here’s a quick look at each, and we’ll explore all three in detail below.

Remember, your retail store layout guides product placement, directs customer flow, and defines the overall look and feel of your store, so it deserves plenty of thought. Many factors will affect your floor plan choice, including the size and shape of your sales floor, the types of products you sell, and even the customers you hope to attract. Keep these factors in mind as we explore each floor plan option in detail.

Steps for Store Layout

Step 1: Decide on a Retail Store Floor Plan

Step 2: Put Your Floor Plan Down on Paper – If you haven’t settled on your store layout, or even if you have, the first thing you need to do is work your plan out on paper. But before you start, remember! Many small retailers find that a mix of floor plan and layout styles works best.

Step 3: Consider Traffic Flow in Your Store Layout – Whichever store layout you choose, you need to arrange your store’s pathways, aisles, and display fixtures with traffic flow in mind. To do this, you must to understand three key customer behaviors.

Store Material Storage and Handling

In a warehouse setting, there are different types of storage media for product handling, manipulation or picking, emanating from four categories – Bulk Storage, Pallet Rack, Shelving and Carton Flow.

Bulk Storage is also known by the name of ‘floor stacked’, and is the most fundamental form of warehousing that comprises the building square footage, and no physical storage medium. Products are directly stored on the warehouse floor deeply inside various pallets and may also be stacked depending upon the type of product. This is a comparatively low cost method, and is most ideal for stacking pallets, while the products are also not susceptible to First-In-First-Out (FIFO) sequencing and storage density. Some of the challenges, however, could low space utilisation, increased risk of product damage with stacking and ineffective product identification and picking owing to cumbersome product access.

Pallet Rack comprises a set of upright frames interlinked in different ways through horizontal beams to accommodate palletised or non-palletised products according to rack configuration and the use of beam supports.

Shelving is of two kinds, viz. Wide Span Shelving and Industrial Shelving. Wide span shelving is a lighter duty version of standard pallet rack, ideal for cartons, tote storage, hand stacked storage, etc. It offers similar versatility, sizing and access as selective pallet rack, and can also be stacked to create shelf-supported mezzanine structure to maximise vertical storage. Industrial shelving offers multiple storage levels or picking in a quite small footprint, with a storage capacity of 300-1000 lbs per shelf level. Industrial shelves can be dividers or drawers that are mostly used in automotive and electronic industries for picking small parts.

Carton Flow usage depends on factors such as overall footprint availability, product size and weight consistency, SKU quantity and velocity, and so on. After proper estimation of the benefits and drawbacks related to making use of valuable space for setting up a carton flow picking area, the next step is to decide on the carton flow type to be used. The weight, size and consistency of such variables will depict the best carton flow type for application. There are lots of differences in requirements for carton flow for a warehouse picking the product, with that of box weight and sizes and a warehouse where shape and size differ hugely. In addition, warehouse environmental conditions also play a pivotal role in the product to be chosen.

There are few fundamental kinds of carton flow, which manufacturers provide different versions of, to distinguish themselves from their competitors. Let’s take a look at the following basic ones:

- Wheel track

- Full width roller

- Skate wheel

These types can be either configured as standalone units, or rows combined together into a new pick module.

Wheel Track – This carton flow type normally comprises a frame or shelf assembly, rails or wheel tracks and dividers. The frame is bolted, bracketed or welded, where the wheel tracks measure about 1 inch wide roll formed channels with amalgamated plastic wheels on approximately 2 inch centers, and the wheels may or may not have axles. Dividers are also mostly full length and adjustable. Wheel tracks and dividers are adjustable so as your product mix changes you can modify the carton flow, and can also be replaced when damaged or degraded as they do not constitute a part of a composite unit. Shelves can also combine different accessories for product presentation, and are not bound by the storage media capacity, which enables ergonomic shelf positioning, wherever applicable. Extra tracks can be added to facilitate ease of product travel.

Full Width Roller – This carton flow type normally comprises gravity roller conveyor tracks of different widths, roller capacities and centers. Similar to the wheel tracks, full width rollers depend on pallet rack or standalone supports to accommodate the structural support, and makes use of standard pallet rack beams for installation. The tracks can be limited to the racking depth through rack beams being used as end stops or mounting areas for accessories, or attach atop the beams allowing for more depth, accessory and ergo options. Some need brackets to enable the track to be attached to the beam, while others just lay in place and are safe as is. In case deep lane applications, additional beams may be required for support beyond and above the in-feed and discharge zones, though it is generally achieved through using intermediated beams inside the normal pallet rack structure. Some manufacturers also provide a frame or a shelf allowing accessories to be installed and depth correction beyond beam supports. Full width rollers allow more surface area contact along with better conveyance for products with high humidity environments or flimsy bottoms. Roller centers and track widths can be made adjustments thereof to maintain a balance between functionality and cost. At times, any product overhang is also permitted. Even tracks can be easily installed as new product or in a retrofit. Full width rollers involve in-feed and discharge brackets, along with a lay in section of conveyor, used primarily for rack beam installation.

Skatewheel – This carton flow type is a combination of both the concepts stated above, viz. full width roller and wheel track, and integrates into a fixed width bed of skatewheel. The entire bay width can be covered with the insertion of beds such that there are no gaps left. Lanes are separated through lane entry guides and full length dividers. Even, the wheels can be aligned or staggered as per the manufacturer requirements, and are generally much larger than those present on wheel track rails. There is no loss of pickable space either, as the entire bay is one big carton flow section. Secondly, lane entry guides can be adjusted to accommodate various product sizes or other changes, whereas, the number of wheels per foot can also be adjusted by changing axle centers to lessen costs. Larger wheels offer a low coefficient of friction and are more aligned with full width roller surface area contact, reducing the possibility of boxes that are formed around the wheel in high humidity. Skatewheels are easy to install, and are more identifiable with full width roller installation.