Receiving goods-in or in-handling is a crucial process within the warehouse. Ensuring that the correct product has been received in the right quantity and in the right condition at the right time is one of the mainstays of the warehouse operation. These elements are often termed as supplier compliance.

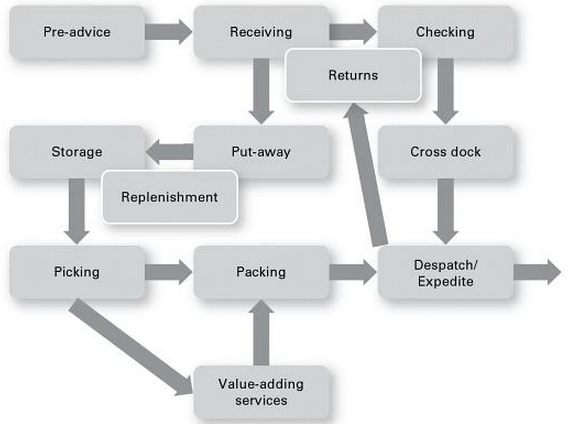

Figure: Warehouse Processes

The receipt of goods into a warehouse needs to be a carefully planned activity. In most large warehouses, incoming vehicle loads are booked in advance so that the appropriate resources can be allocated to the activity. On arrival, drivers report to the gatehouse, where staff check the vehicle documentation and direct the driver where to go, either directly to an unloading bay or to a parking area.

The vehicle, or container, doors may be sealed, particularly in the case of imported goods. Where this occurs, the seal number needs to be checked against that advised by the sender so that it can be ascertained whether the doors have been opened during transit (and hence there may be the possibility of loss).

On unloading, the goods are normally checked to ensure that they are the correct items and of the required quantity and quality. This may be undertaken by cross-checking against purchase orders, but this can be very time-consuming. An alternative method is for the sender to transmit an advance shipping notice (ASN) by EDI and for this to be related automatically to the appropriate purchase order. The goods can then be checked specifically against the ASN for that vehicle. For approved and trusted suppliers, it may be that the quantity and quality can be assumed to be correct as per the ASN, in which case the goods can be unloaded and transferred immediately to storage.

The unit loads then need to be checked, particularly if they are to be put away into an automated storage and retrieval system. For example, pallets may be weigh-checked on a conveyor and then passed through a dimension checking device, which would register any protrusions outside the permitted dimensions by means of photoelectric cells. Any pallets that do not conform (eg because the cartons have shifted in transit) are then sent to a reject spur on the conveyor for manual rectification.

When the goods are ready for placing into storage, they may be put away and the computer system advised of the location number or, more normally, the warehouse management system would identify the most appropriate location and issue a put-away instruction (eg on a paper put-away sheet or transmitted to a truck driver’s radio data terminal).

A key objective in designing the receiving process is to enable the goods to be put away to the required location in the warehouse with the minimum handling and minimum delay possible. This oft en requires close co-ordination with suppliers, in terms of procurement agreements and the timing of deliveries.