P’s and R’s of Logistics

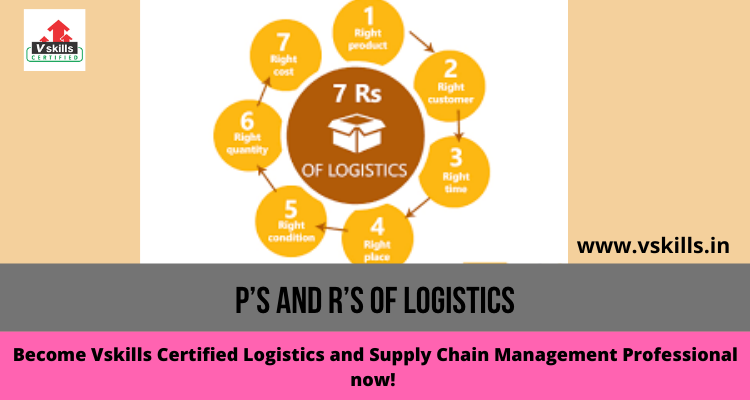

Let’s learn more about P’s and R’s of Logistics. In the quest to provide quality service and satisfy customers, world-class companies along the supply chain are guided by the Seven Rights of Fulfillment.

- The Right Product

- To the Right Customer

- At the Right Time

- At the Right Place

- In the Right Condition

- In the Right Quantity

- At the Right Cost

Logistics provide a link between two primarily functions in a manufacturing organization – Marketing & Operations and the following 5P structure helps in deciding on the fundamentals for a sustainable efficiency in the system.

- Product: The product is the physical product or service offered to the consumer. In the case of physical products, it also refers to any services or conveniences that are part of the offering. Product decisions include aspects such as function, appearance, packaging, service, warranty, etc.

- Price: Pricing decisions should take into account profit margins and the probable pricing response of competitors. Pricing includes not only the list price, but also discounts, financing, and other options such as leasing.

- Promotion: Promotion decisions are those related to communicating and selling to potential consumers. Since these costs can be large in proportion to the product price, a break-even analysis should be performed when making promotion decisions. It is useful to know the value of a customer in order to determine whether additional customers are worth the cost of acquiring them. Promotion decisions involve advertising, public relations, media types, etc.

- People: People decisions are those related to customer service. The function of people to present an appearance, an attitude, etc

- Place: Place (or placement) decisions are those associated with channels of distribution that serve as the means for getting the product to the target customers. The distribution system performs transactional, logistical, and facilitating functions. Distribution decisions include market coverage, channel member selection, logistics, and levels of service.

Logistics of Services

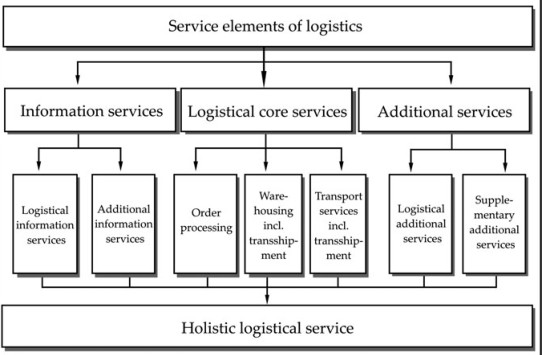

The logistical system of services features a wide range of system components, which are illustrated in figure below.

The core services of logistics, such as order processing, storage and transport, are directly supported by the logistical information services and the additional services necessary for the logistics process. In practice, the element of transshipment is rarely dealt with separately since it is usually closely connected to storage and transport. The core element of order processing is some-what virtual in nature but constitutes an indispensable element for the initiation and monitoring of logistics processes. It is the order processing which gives logistics its dynamic character. Order processing comprises the processing and monitoring of the order data from the time of order until the arrival of the goods at the customer’s site and of the return of the shipment documents. In many cases this includes the initiation of invoicing processes, e.g. by simultaneously delivering the invoice together with the goods.

The core element of storage denotes the warehousing of goods, which have mostly been produced for an anonymous market to offset the quantitative and chronological divergence of production (supply) and sales (demand). It has to be noted at this point that the functions of picking and packing, which are closely connected to the core element of storage, fall into the category of additional services. Picking means the compilation of sellable articles according to individual customer orders to form package and shipping units.

Finally, the core function of transport bridges the spatial distance from the site of production to the storage location to the delivery location at the customer’s site. Thus, it offsets the spatial divergence of supply and demand. Again it has to be pointed out that both storage and transport include the function of transshipment. Logistical information services produce and utilize data about the goods being transported within the logistics system. This data includes information about the forwarder, the recipient, the type of goods, order number, quantity, weight, volume etc. The logistical information is the key to planning, monitoring and supervising the provision of the actual logistics service. A data-driven logistical activity closely connected to the core service of storage is the inventory management.

Additional services of logistics include, for instance, picking, palletizing of goods for economical shipping (easier loading and transport), additional packaging for protection, identification and easier handling of goods and commodities, repackaging of goods from bulk packaging into smaller package units etc. Supplementary information services and additional services can usually be incorporated into the logistical core process without expanding further organizational effort. In this way, substantial additional value can occasionally be created for the contractor of the logistical service.

Case Study: Module Assembly – BMG (a module assembly company) is a fully owned subsidiary of the logistics provider Schnellecke. BMG has been entrusted by Volkswagen Braunschweig with the assembly of the modules Subframe and Cornermodule, pertaining to the car models Golf and Passat, for Volkswagen Sachsen Ltd. in Zwickau [additional service]. The service provider is also responsible for the disposition and storage of the primary material [logistical core service] and for the delivery of the assembled modules to the assembly line [logistical core service]. The assembly and delivery for each particular production sequence is carried out according to the logistics planning of Volkswagen Sachsen Ltd.