Production control is the activity of monitoring and controlling a large physical facility or physically dispersed service. It is a “set of actions and decision taken during production to regulate output and obtain reasonable assurance that the specification will be met.” The American Production and Inventory Control Society, nowadays APICS, defined production control in 1959 as:

Production control is the task of predicting, planning and scheduling work, taking into account manpower, materials availability and other capacity restrictions, and cost so as to achieve proper quality and quantity at the time it is needed and then following up the schedule to see that the plan is carried out, using whatever systems have proven satisfactory for the purpose.

Production planning and control in larger factories is often run from a production planning department run by production controllers and a production control manager. Production monitoring and control of larger operations is often run from a central space, called a control room or operations room or operations control center (OCC).

The emerging area of Project Production Management (PPM), based on viewing project activities as a production system, adopts the same notion of production control to take steps to regulate the behavior of a production system where in this case the production system is a capital project, rather than a physical facility or a physically dispersed service.

Production control is to be contrasted with project controls. As explained, project controls have developed to become centralized functions to track project progress and identify deviations from plan and to forecast future progress, using metrics rooted in accounting principles.

PAC

Production activity control (PAC) is responsible for executing the master production schedule and the material requirements plan. At the same time, it must make good use of labor and machines, minimize work-in-process inventory, and maintain customer service.

The material requirements plan authorizes PAC: to release work orders to the shop for manufacturing, to take control of work orders and make sure they are completed on time, to be responsible for the immediate detailed planning of the flow of orders through manufacturing, and to manage day-to-day activity and provide the necessary support. The activities of the PAC system can be classified into planning, implementation, and control functions.

The flow of work through each work center must be planned. PAC must ensure that the required resources are available to manufacture the components as needed and develop a load profile for each work center to ensure the timely completion of orders by the scheduled date.

Next we implement the plan. PAC will gather the information needed by the shop floor to make the product and release orders to the shop floor as authorized by the material requirements plan (dispatching).

Monitor the process and determine the necessary corrective action. PAC will rank the shop orders in desired priority sequence by work center and establish a dispatch list, track actual performance to plan and take corrective action by replanning, rescheduling, or adjusting capacity to meet delivery.

Understand the characteristics and differences between flow, intermittent and project manufacturing .

With the help of the Production Activity Control, one can easily meet the timely completion of the various orders by starting the various operations in time as per the plan. Effective Production Activity Control is also responsible for meeting the delivery commitments. Production Activity Control acts as the modules of the MRP/ERP systems, and involves mainly four procedures – releasing, scheduling, monitoring, updating.

According to McMahon, a simple Production Activity Control architecture consists of the following five building blocks –

- Scheduler

- Dispatcher

- Monitor

- Mover

- Producer

Functions of the Production Activity Control

- Helps in the planning.

- Helps in the execution of the plan.

- Ensures availability of the resources.

- Releases the shop orders.

- Schedules start and completion dates of the jobs.

- Collects required information for the shop order.

- Helps in controlling the operations.

- Establishes order priority.

- Maintains order priority.

- Checks actual performance.

- Monitors and controls WIP, lead times.

- Reports work center performance.

Role of the Production Activity Control

- Manages the shop floor production task.

- Controls the production work flow.

- Aims achievement of the production plans.

- Prepares the schedules.

PAC Process

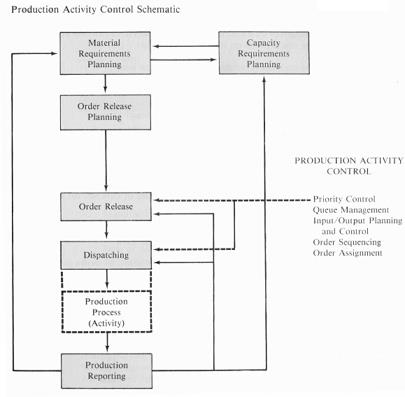

The time arrives when plans must be executed, when material requirements planning and capacity requirements planning have been completed and the detail purchasing and production schedules must be determined and released for execution. The function of production activity control (PAC)–often called shop floor control (SFC)—is to have activities performed as planned, to report on operating results, and to revise plans as required to achieve desired result

Order release, dispatching, and progress reporting are the three primary functions of PAC. Dispatching is the activation of orders per original plans. Dispatching decisions are affected by queue management, I/O control, and priority control principles and techniques that are intertwined and mutually supportive. They are useful in the management of lead-time, queue length, work center idle time, and scheduled order completion. Reports on the status of orders, materials, queues, tooling, and work center utilization are essential for control. Many report types with various information are possible. Examining a given situation will reveal which reports and information are required.

Production activity control (PAC) is responsible for executing the MPS and the MRP. At the same time, it must make good use of labor and machines, minimize work-in-process inventory and maintain customer service.

The MRP authorizes PAC:

- To release work orders to the shop for manufacturing;

- To take control of work orders and make sure they are completed on time;

- To be responsible for the immediate detailed planning of the flow of orders through manufacturing, carrying out the plan and controlling the work as it progresses to completion;

- To manage day-to-day activity and provide the necessary support.

Planning – The flow of work through each of the work centers must be planned to meet delivery dates, which means PAC must do the following:

- Ensure that the required materials, tooling, personnel and information are available to manufacture the components we needed;

- Schedule start and completion dates for each shop order at each work center so the scheduled completion date of the order can be met. This will involve the planner in developing a load profile for the work centers.

Implementation – Once the plans are made, PAC must put them into action by advising the shop floor what must be done. Usually instructions are given by issuing a shop order. PAC will:

- Gather the information needed by the shop floor to make the product;

- Release orders to the shop floor as authorized by the MRP. This is called dispatching.

Control – Once plans are made and shop orders released, the process must be monitored to learn what is actually happening. The results are compared to the plan to decide whether corrective action is necessary. PAC will do the following:

- Rank the shop orders in desired priority sequence by work center and establish a dispatch list based on this information;

- Track the actual performance of work orders and compare it to planned schedules. Where necessary, PAC must take corrective action by replanning, rescheduling or adjusting capacity to meet final delivery requirements;

- Monitor and control work-in-process, lead times and work center queues;

- Report work center efficiency, operation times, order quantities and scrap.

Dispatch list – Once all the operations are scheduled and the material has been picked and delivered to the work center, you can print a dispatch list to keep track of work order and work center status. A dispatch list (or query) displays by work center all work orders with operations scheduled for that work center in the following order:

- All work orders, completed but not yet moved to another work center.

- All active (started) work orders (in-process and in-setup).

- All work orders which are ready to start (in queue and coming).

- All work orders on hold.