This manual form of operation has led to an increase in the use of technology. The lists of benefits are stated as being very comprehensive. They include,

- increased accuracy

- increased productivity

- reduction in paper usage

- reduction in errors through elimination of re-keying data

- improved safety through hands- and eyes-free operation

- reduction in damage

- real-time stock updates leading to fast and accurate

- replenishment

- real-time updates regarding potential shortages

- increased time on the warehouse floor

- reduced training times

- multilingual, accommodating a diverse workforce

- easy to integrate with other systems

- potential reduction in employee turnover

- normally a quick ROI

This system has become prevalent in the food service and grocery retail sector. It is particularly suitable for both chilled and frozen environments where gloves hamper the use of radio data terminals (RDTs) and paper, while the hands-free aspect of the system has major advantages over paper pick lists, labels and barcode scanning. Increased accuracy can negate the need for additional checks at dispatch. The reduction in picking errors is significant in most of the companies who have adopted this technology. Some companies have introduced a failsafe by scanning the item once picked. For high-volume operations, even small improvements in accuracy can produce a substantial payback. For example, a warehouse that picks half a million cases per week with a 99.8 per cent accuracy level (two errors per thousand) incurs 52,000 errors per annum. Increasing accuracy to 99.96 per cent or 0.4 per thousand, for example, will reduce errors by 41,600 per annum.

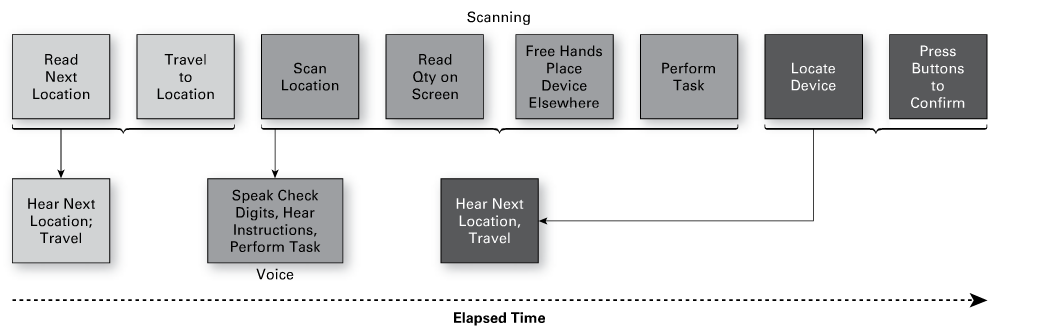

Following figure displays why voice outperforms scanning.

Voice needs to be supplemented by some form of scanning or image-capture technology for 100% accuracy. Some companies have supplemented voice confirmation of quantity with product recognition by repeating the last four digits of the barcode.

Voice technology thus helps in improving accuracy, increasing productivity and improving ergonomics, which reduces staff illness and, leads to improved customer service. A number of manufacturers have introduced a combined voice and automated guided vehicle (AGV) or laser-guided forklift truck system.

The AGVs feature a laser navigation steering system which charts the picker’s route. At the first location the voice system instructs the picker as to which item should be loaded onto the empty pallet. The picker informs the system what has been picked and loaded and the truck continues to the next location without the operator having to control it.