Let’s learn more about PDCA. W. Edwards Deming in the 1950’s proposed that business processes should be analyzed and measured to identify sources of variations that cause products to deviate from customer requirements. He recommended that business processes be placed in a continuous feedback loop so that managers can identify and change the parts of the process that need improvements. As a teacher, Deming created a (rather oversimplified) diagram to illustrate this continuous process, commonly known as the PDCA cycle.

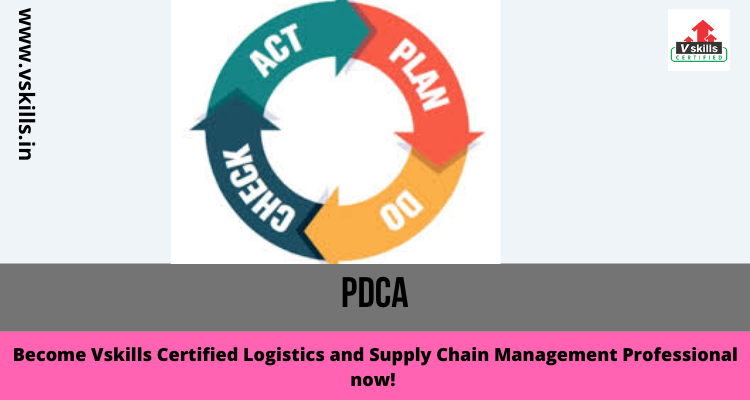

The plan–do–check–act cycle (Figure 1) is a four–step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement.

Figure 1: Plan-do-check-act cycle

When to Use Plan–Do–Check–Act

- As a model for continuous improvement.

- When starting a new improvement project.

- When developing a new or improved design of a process, product or service.

- When defining a repetitive work process.

- When planning data collection and analysis in order to verify and prioritize problems or root causes.

- When implementing any change.

Plan–Do–Check–Act Procedure

- Plan: Recognize an opportunity and plan a change.

- Do: Test the change. Carry out a small-scale study.

- Check: Review the test, analyze the results and identify what you’ve learned.

- Act: Take action based on what you learned in the study step: If the change did not work, go through the cycle again with a different plan. If you were successful, incorporate what you learned from the test into wider changes. Use what you learned to plan new improvements, beginning the cycle again.

A fundamental principle of the scientific method and PDCA is iteration—once a hypothesis is confirmed (or negated), executing the cycle again will extend the knowledge further. Repeating the PDCA cycle can bring us closer to the goal, usually a perfect operation and output.

Another fundamental function of PDCA is the “hygienic” separation of each phase, for if not properly separated measurements of effects due to various simultaneous actions (causes) risk becoming confounded.

In Six Sigma programs, the PDCA cycle is called “define, measure, analyze, improve, control” (DMAIC). The iterative nature of the cycle must be explicitly added to the DMAIC procedure.

Rate of change, that is, rate of improvement, is a key competitive factor in today’s world. PDCA allows for major “jumps” in performance (“breakthroughs” often desired in a Western approach), as well as Kaizen (frequent small improvements). In the United States a PDCA approach is usually associated with a sizable project involving numerous people’s time, and thus managers want to see large “breakthrough” improvements to justify the effort expended. However, the scientific method and PDCA apply to all sorts of projects and improvement activities.