Sigma Level

To better understand the sigma level, you need to know the DPMO numbers and the corresponding sigma values. A DPMO of 690,000 equates to 1.0 sigma; a DPMO of 308,000 is 2.0 sigma; 66,800 is 3.0 sigma; 6,210 is 4.0 sigma; 320 is 5.0 sigma; and 3.4 is 6.0 sigma. In the example with the DPMO calculation of 15,000, the sigma level falls between 3 and 4. On a bell-shaped curve, that’s plus or minus three standard deviations to the left and to the right of the mean.

The Six Sigma method measures the capability of a process using the ‘sigma level’. The aim is to achieve a sigma level of at least six, which equates to less than 3.4 DPMO.

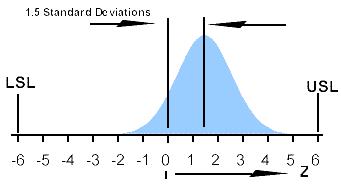

The Sigma level is calculated using the normal distribution. The idea is that the span between the upper and lower specification limits should be at least 12 standard deviations (six standard deviations on each side). Because it is not usually practical to set the processes mean exactly on target, and the mean of most processes is subject to drift, a 1.5 standard deviation offset is assumed in converting between DPMO and Sigma Level.

Other sigma levels are:

| Sigma Level | Parts Per Million (PPM) |

| 3 | 66811 |

| 4 | 6210 |

| 5 | 233 |

| 6 | 3.4 |