The traditional view of manufacturing management began in eighteenth century when Adamsmith recognised the economic benefits of specialization of labour. He recommended breaking of jobs down into subtasks and recognises workers to specialized tasks in which they would become highly skilled and efficient. In the early twentieth century, F.W. Taylor implemented Smith’s theories and developed scientific management. From then till 1930, many techniques were developed prevailing the traditional view. Production Management became the acceptable term from 1930s to 1950s. As F.W. Taylor’s works become more widely known, managers developed techniques that focused on economic efficiency in manufacturing. Workers were studied in great detail to eliminate wasteful efforts and achieve greater efficiency. At the same time, psychologists, socialists and other social scientists began to study people and human behaviour in the working environment. In addition, economists, mathematicians, and computer socialists contributed newer approaches. With the 1970s emerged other two distinct changes. The most obvious of these, reflected in the new name Operations Management was a shift in the service and manufacturing sectors of the economy. As service sector became more prominent, the change from ‘production’ to ‘operations’ emphasized the broadening of field to service organizations. The second, more suitable change was the beginning of an emphasis on synthesis, rather than just analysis, in management practices.

A brief account of development of operations and production management is as

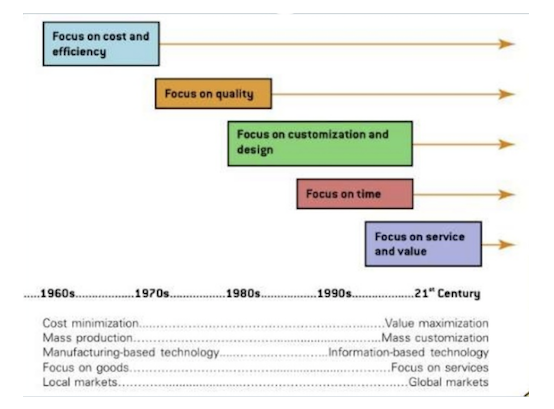

In the last century, operations management has experienced more changes than any other functional area of business and is the most important factor in competitiveness. This is a chronology of major themes that have changed the scope and direction of operations management:

The evolution of operation management (OM) in terms of changes in approaches for manufacturing and operations, can be summarized as

Focus on efficiency

OM has it’s roots in the Industrial Revolution that occurred during the late 18th and early 19th centuries in England. Until that time, goods had been produced without the aid of mechanical equipment. During the Industrial revolution many inventions came into being that allowed goods to be manufactured with greater ease and speed; it lead to the development of modern factories. As international Trade grew the emphasis on operations efficiency and cost reduction increased. Many companies moved their factories to low-wage countries. Technology was viewed primarily as a method of reducing costs and distracted from the importance of improving quality.

Quality revolution

US consultants told Japanese executives that continual improvement of quality would open world markets, free up capacity and improve the economy. They embarked on a massive effort to train the workforce, using statistical tools to identify causes of quality problems and fix them; so that the made steady progress in reducing defects and paid attention to consumer needs. Thanks to this progress Japanese good were seen as more reliable and better met consumer needs, then Japanese firms captured major shares of world market. Therefore, quality became an obsession with top managers.

Customization and design

As the goals of low cost and high quality became given , companies began to emphasize innovative designs and product features to gain a competitive edge. Quality meant much more than simply defect reduction; quality meant offering consumer new and innovative products , not only meeting their needs but surprising and delighting them . Inflexible mass production methods that produced high volumes of standardized goods and services using unskilled or semiskilled workers and expensive single-purpose equipment, thought very efficient and cost effective, were inadequate for the new goals of increased G&S variety and improvement .

Time–based competition

Companies have to respond quickly to changing customer needs to win competitive advantage. That task includes developing products faster than competitors, speeding ordering and delivering process, rapidly responding to changes in customers’ needs and improving the flow of paperwork. As information technology matured, time became an important source of competitive advantage.

Service revolution

While the goods-producing industries were getting all the attention in the business community, the popular press and in business school curricula, service industry were quietly growing and creating many jobs. Today about four out of five jobs in the US are in the service sector.