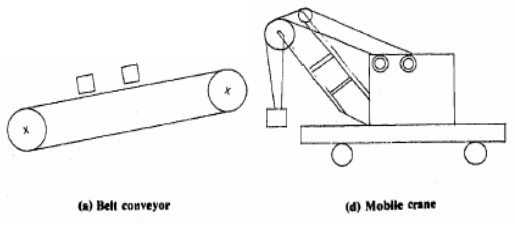

After the simplification of the handling method the selection of equipment is important with respect to the different objectives of speed, efficiency-cost etc. There are both the manual and powered kind of handling equipments. Some of the typical handling equipments arc shown in Figure VIII Apple (1977) has classified the handling equipments into four basic types, viz., conveyers, cranes and hoists, trucks, and auxiliary equipment.

Conveyers

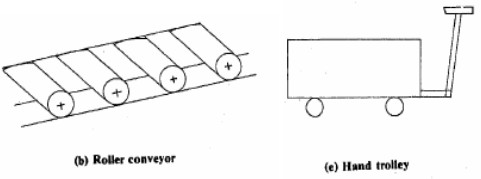

These are gravity or powered devices commonly used for moving uniform loads from point to point over fixed paths, where the primary function is conveying. Commonly used equipment under this category are:

- Belt Conveyer

- Roller Conveyer

- Chain Conveyer

- Bucket Conveyer

- Trolley Conveyer

- Screw Conveyer

- Pipeline Conveyer

- Vibratory Conveyer

Cranes, Elevators and Hoists

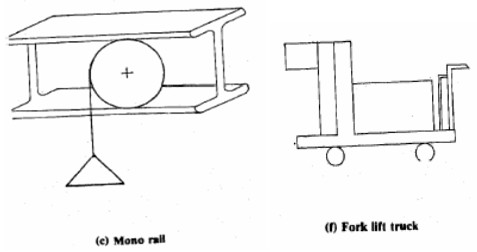

These are overhead devices used for moving varying loads intermittently between points within an area, fixed by the supporting and binding rails, where the primary function is transferring or elevating. Some common examples are:

- Overhead traveling crane

- Gantry crane

- Jib crane

- Elevators

- Hoists

- Stacker crane

- Winches

- Monorail

Industrial Trucks and Vehicles

These are hand operated or powered vehicles used for movement of uniform or mixed loads intermittently over various paths having suitable running surfaces and clearances where the primary function is maneuvering or transporting. These include:

- Fork lift truck

- Platform truck

- Industrial tractors and traitors

- Industrial cars

- Willkie truck

- Two wheeled hand truck or trolley

- Hand stacker

Auxiliary Equipment

These are devices or attachments used with handling equipment to make their use more effective and versatile. Some common examples are:

- Ramps

- Petitioners

- Pallets and skids

- Pallet loaded and unloaded

- Lift truck attachments

- Dock boards and levelers

- Containers

- Below the hook devices

- Weighing equipment