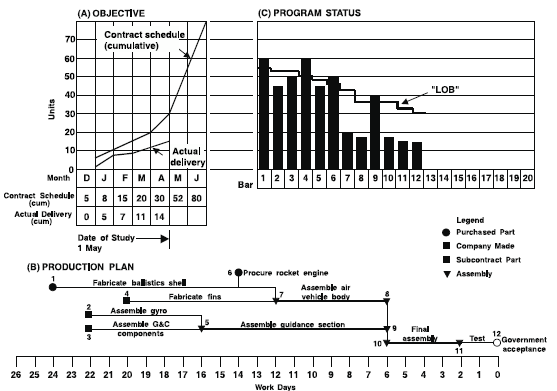

Line of Balance (LOB) is a management control process for collecting, measuring and presenting facts relating to time (see Schedule Control), cost and accomplishment – all measured against a specific plan. It shows the process, status, background, timing and phasing of the project activities, thus providing management with measuring tools that help:

- Comparing actual progress with a formal objective plan.

- Examining only the deviations from established plans, and gauging their degree of severity with respect to the remainder of the project.

- Receiving timely information concerning trouble areas and indicating areas where appropriate corrective action is required.

- Forecasting future performance.

The LOB itself is a graphic device that enables a manager to see at a single glance which activities of an operation are “in balance” – i.e., whether those which should have been completed at the time of the review actually are completed and whether any activities scheduled for future completion are lagging behind schedule. The LOB chart comprises only one feature of the whole philosophy which includes numerous danger signal controls for all the various levels of management concerned.

To do LOB, the following is needed:

- A contract schedule, or objective chart;

- A production plan or lead-time chart for the production process itself;

- Control points cumulative inventories; and

- A program status chart on which to plot LOB and the cumulative quantities of units that have passed through the control points of the assembly/production process.