Lean focuses on lean philosophy which is about elimination of waste in all forms at the workplace. Specific lean methods include just-in-time inventory management, Kanban scheduling systems and 5S workplace organization.

Many of these concepts were developed by a Japanese company, Toyota which is an automobile manufacturer in the 1940s and these concepts became widespread for removing waste thus, graduating as best practices in many industries beyond automotive companies. Applying these principles to production has the potential for both improved profitability and increased complexity.

Lean Origins

Lean Manufacturing has evolved over times. In 1890’s Frederick W. Taylor began to look at individual workers and work methods. Frank Gilbreth added Motion Study and invented Process Charting. Lillian Gilbreth introduced psychology by studying the motivations of workers and how attitudes affected the outcome of a process. These ideas led to waste elimination, a key component of JIT and Lean Manufacturing.

In 1910, Henry Ford developed and implemented the first comprehensive Manufacturing Strategy by arranging all the elements of a manufacturing system like people, machines, tooling and products, in a continuous system or an assembly line for manufacturing the Model T automobile.

Toyota Production System

During 1949 and 1975, in Toyota Motor Company, Taichii Ohno and Shigeo Shingo, began to incorporate Ford production and other techniques into an approach called Toyota Production System or Just In Time. But, they found flaws in the Ford system, especially with treatment towards employees as Ford used employees only for muscle power.

The Toyota Production System (TPS) focuses on muri and muda. Muri focuses on the preparation and planning of the process, or what work can be eliminated in the design process. Muda are those waste steps and processes that add cost. Muri is used in new product design and muda is used to improve existing operations.

Lean Concept and Tools

Lean is not just usage of few techniques or processes but a journey in itself which takes a holistic view of the organization and involves various phases which make use of various techniques and processes. The process for lean manufacturing involves following steps

- Define value from the customer’s perspective

- Map the value stream

- Create flow by removing causes of waste

- Create pull if flow is difficult to achieve

- Measure and validate

- Practice continuous improvements

Lean Process

There are four key Lean concepts: identifying value, the value stream, pull, and perfection. There are four key Lean concepts, which can be visualized as a pyramid. The base of the pyramid being identifying value, the value stream as the next level, then pull as the third level, and the topmost level being perfection.

Identifying value

Identifying value should always start with the customer, who you ship the product or service to, or the downstream process customers. If an activity doesn’t add value for a customer, then it’s a sign that it’s a process that needs to be improved. Identifying value is important, as it defines direction for the organization. Examples of activities that don’t add value include wasted movement, re-work, or extra inspection time because you don’t trust the process to get it right the first time. Then think about what it is that creates value in a process or product. A good way to do this is to look at it from the customer’s point of view to see what they perceive as value and then try to determine what brings the most value for the organization.

The value stream

The next Lean concept is called the value stream, which is any series of activities and processes that create value in an organization. To determine the value stream, you use the technique called value stream mapping. Value stream mapping requires that you capture lots of data such as cost and quality data. The data gathering should include suppliers and customers as well. Once all the information is processed, you can decide whether any activities or processes need to be restructured in order to improve overall performance. One technique that you can use is to create current state maps with data, and then think about future state maps and look at the differences between the two.

The pull system

The next important concept is the notion of pull. This is the idea that instead of pushing inventory through planning into the system, you actually allow the customer to trigger a pull through of inventory or information to support downstream processes based on consumption. By doing that, you can greatly reduce and eliminate wait time that’s associated with traditional planning processes. In addition, this will lead to minimal inventory being required.

Perfection

The final concept is perfection. A dedication to continuous improvement is absolutely critical in the practice of Lean. All organizations would quickly agree that from a safety perspective, the only acceptable goal for safety would be zero – zero injuries, deaths, lost time, accidents, or even near misses. You need to have to have the same attitude toward waste and defects in your processes. Zero is the only acceptable goal. You may never actually get to zero but there needs to be committed, continuous improvement to drive perfection. It’s also important that the customer’s voice is heard regarding the elimination of waste and in determining what value-add means.

Value in Lean

Value is how well a product or service actually meets your customer’s requirements. It’s very important to work out early on if a customer is willing to pay for the product or service. If the answer to that is clearly a yes, then you can say that this has value. Therefore value-added would be activities that actually add value to the end product and drive what your customer is willing to pay for in that product or service.

Value addition can be gauged by breaking down each activity in the process, using value stream mapping. Then for each step, ask these questions

- Does it fulfill your customer’s need or preference?

- Does it physically change something about the product or service?

- Is it done right the first time?

If you can’t answer yes to all the questions, then the step may not actually be adding any value in the process.

Mudas and 3Ms

Muda is a Japanese term meaning “waste” as, lean manufacturing is an Japanese management philosophy hence, Japanese terms and concepts are used extensively. There are 7 mudas or seven types of waste that are found in a manufacturing process which are

- Overproduction – Producing more than the customer requires is waste causing other wastes like inventory costs, manpower and conveyance to deal with excess product.

- Needless Inventory – Inventory at any point is a no value-add as it ties up financial resources of the company and is exposed to the risk of damage, obsolescence, spoilage, and quality issues. It also needs space and other resources for proper management and tracking.

- Defects – Defects and broken equipment results in defective products and subsequently customer dissatisfaction, which need more resources for solving.

- Non-value Processing – It is also called over-processing, for which more resources are wasted in production, their wasted movement and time. Any processing that does not add value to the product is waste like in-process protective packaging due to extra manufacturing steps.

- Excess Motion – Unnecessary motion due to poor workflow, poor layout, housekeeping, inconsistent work methods or lack of standardized procedures, is a waste.

- Transport and Handling – It is shipping damage and includes pallets not being properly stretch wrapped (wasted material), or a truck is not loaded to use floor space efficiently.

- Waiting – These are wastages in time, due to broken machinery, lack of trained staff, shortages of materials, inefficient planning and waiting for material.

3Ms

When Japanese companies talk about waste they usually talk about the three Ms; Mura, Muri and Muda. While most people who have had contact with lean manufacturing will have been made aware of the 7 wastes and Muda they often have not been introduced to Muri and Mura at all. Yet these wastes are often far more important to tackle than Muda and often are the underlying causes of the Muda that you observe within your processes.

While Muda is the non-value adding actions within your processes; Muri is to overburden or be unreasonable while Mura is unevenness. There are 8 distinctive types of muda which all lead to waiting times, and therefore longer lead times in a process. Simply taking out the muda does not work. Usually, there is a reason why the muda is there and this reason often has to do with the other two enemies: muri and mura. This means the three enemies of Lean are interrelated and should therefore be taken into account simultaneously. The three enemies of lean can be found in both production and office processes.

Mura is the waste of unevenness or inconsistency. Mura creates many of the seven wastes that we observe, Mura drives Muda! By failing to smooth our demand we put unfair demands on our processes and people and cause the creation of inventory and other wastes.

Muri is to cause overburden, by this we mean to give unnecessary stress to our employees and our processes. This is caused by Mura and a host of other failures in our system such as lack of training, unclear or no defined ways of working, the wrong tools, and ill thought out measures of performance. Again Mura causes Muda, the seven wastes are symptoms of our failure to tackle Mura and Muri within our processes not the root cause!

Waste Elimination Techniques

Various waste elimination techniques which are used in lean manufacturing are listed, as

- Pull System – It is the technique for producing parts as per the customer’s demand. Companies need to have a Push System or building products to stock as per sales forecast, without firm customer orders.

- Kanban – It is a method for maintaining an orderly flow of material. Kanban cards are used to indicate material order points, how much material is needed, from where the material is ordered, and to where it should be delivered.

- Total Quality Management – It is a management system for continuous improvement in all areas of a company’s operation. It is applicable to every operation of the organization and involves employees.

- Quick Changeover (or SMED – Single Minute Exchange of Dies) – It is the technique for reducing changeover time to change a process from running a specific product manufacture to another. It enables flexibility in final product offerings and also to address smaller batch sizes.

- 5S or Workplace Organization – It is a systematic method for organizing and standardizing the workplace and is applicable to every function in an organization.

- Total Productive Maintenance – It focuses on proactive and progressive maintenance of equipments by utilizing the knowledge of operators, equipment vendors, engineering and support persons to optimize machine performance thus, drastically reducing breakdowns, unscheduled and scheduled downtime which results in improved utilization, higher throughput, and better product quality.

- Takt time is a measure of customer demand expressed in units of time and is calculated as Takt time = Available time per shift / Demand per shift or Cycle time/Number of People

- Visual Controls – They provide an immediate understanding (usually thirty seconds) of a condition or situation like what’s happening with regards to production schedule, backlog, workflow, inventory levels, resource utilization, and quality. It includes kanban cards, lights, color-coded tools, lines delineating work areas and product flow, etc.

- Poka Yoke or Mistake Proofing – Poka Yoke is a quality management concept developed by a Matsushita manufacturing engineer named Shigeo Shingo to prevent human errors from occurring in the production line as, extensive automation and computerization is expensive. Poka yoke is implemented by using simple objects like fixtures, jigs, gadgets, warning devices, paper systems, and the like to prevent people from committing mistakes.

Value Stream Mapping or VSM

Value refers to an activity for which customer will pay for or which is valued by the customer and rest are non-value activities. Value stream refers to the sequence of activities involved from

customer’s request ion to fulfillment and VSM records these activities as icons or symbols.

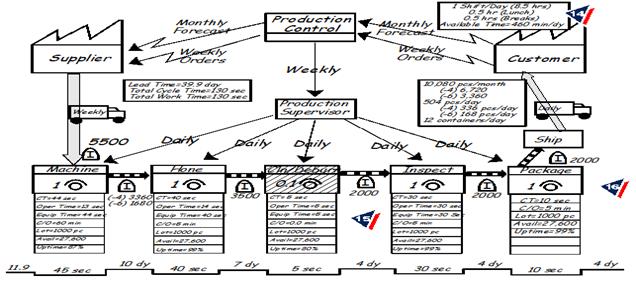

Value Stream Mapping (VSM) is a visualization tool oriented to understand and streamline work processes using icons and symbols to depict various elements and improve the flow of material and information. It helps in identifying and decreasing waste or non-value addition, in the process. It can also be used as a strategic planning tool and a change management tool other than a communication tool.

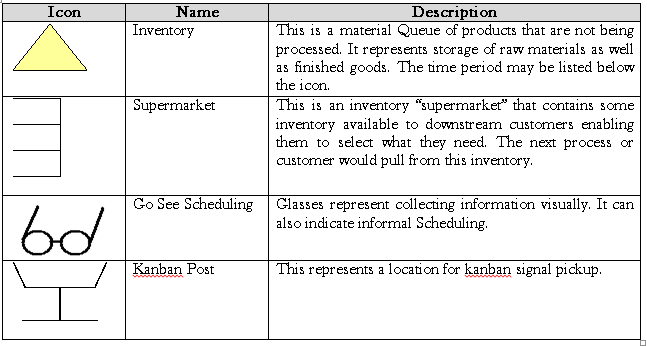

Few icons used for mapping and development of VSM, includes

Developing the VSM – VSM mapping involves step by step development of the VSM state map whether a present or of future state map and involves the following steps

- Draw customer, supplier and production control icons.

- Enter customer requirements and calculate daily production required.

- Draw outbound shipping icon and truck with delivery frequency.

- Draw inbound shipping icon, truck and delivery frequency.

- Add process boxes, in sequence, left to right, and data boxes below.

- Add communication arrows with methods and frequencies.

- Obtain process attributes and add data boxes.

- Add operator symbols, inventory locations and levels in days of demand graph at bottom.

- Add push, pull and FIFO icons.

- Add working hours, cycle times (CT) and lead times.

- Calculate total cycle lead time.

Just-in-time

One of the commonly used Lean tools is just-in-time (JIT). Just-in-time is very important because it’s a very clear and easy to execute control of inventory process. It controls the flow of materials and products to meet that customer demand drumbeat or Takt time. There is no or minimal waiting with a well-executed JIT system. As one item is used, you’re able to get another one immediately and move on. This serves to minimize waste such as storage costs.

A key feature of JIT is it’s based on the pull manufacturing approach, which is driven by various kinds of signals such as kanban, visual signals, Heijunka box, or other techniques like that. The benefit of that is it helps create synchronization between assembly lines. You can actually have visual signals to JIT, to pull in sub-assemblies and components, just when needed for finished products. This, in turn, results in a much smoother flow of production, and reduces overall inventory cost to operate the business.

Poka-yoke

Poka-yoke is another important aspect in the application of Lean in both production and service environments. Poka-yoke translates roughly in Japanese as mistake proofing. What you’re doing with error-proofing methods and poka-yoke is determining where human errors can occur in a process. Then, you need to work at continually eliminating the opportunities for mistakes and making it easy for the human being to get it right the first time. Suppose, in an assembly area, a product is going to be assembled with screws. Each product requires ten screws, so the assembly area is set up with ten screws only. Once all ten screws are used, it would be a visual signal that there are none leftover. An example in the service sector could be using color-coded forms. Or maybe the information technology system won’t allow you to exit a screen until you properly fill in only allowable values in certain fields.

Types of poka-yoke devices

- Checklists – These are methods you can use so that you don’t forget the important things that need to happen and ensure that things are happening in the correct order to get a quality result out of the process.

- Screening – A very powerful technique that gives you the ability to force the acceptance of only legitimate values or options within a given process.

- Signaling – Andon lighting or signaling methods are very powerful with different colors of lights denoting different actions by the support team.

- Control methods – Control methods such as color coding or providing racking so that you can have smooth movement of material without injuries or safety problems. This also prevents damage to the product.

Kanban

Kanban is a Japanese term associated with the notion of a white card or a card that you can see and touch. But it could be any form of a signal that can be used to pull materials into the value stream. For example, it could be colored golf balls, bins or containers, empty spaces on the floor or shelf, lights, or sounds. Many advantages flow from using kanban and pulls associated with avoiding overproduction and by only making what’s needed when needed. By ensuring that there is enough material in the system to meet all requirements to pull things through, you will be able to reduce inventory to just the absolute minimum levels to provide buffers. This would also have the effect of improving product quality as there is lot less in the system that could require fixing. However there is also a major disadvantage – whenever there is a disruption in the delivery of materials it can cause a kanban system to break down.

The kanban pull

A simple production cycle consists of a supplier providing raw material to a production process, which in turn provides a product to a customer. When the customer, who could be the end customer or a downstream operation, uses a standard amount of material for a process, they create a kanban pull. This could be a physical ticket, a container, or a signal that’s going upstream. This authorizes the feeder operation, or production, to produce another standard amount and ship it down to the customer. When the production consumes the raw materials in turn, a second kanban pull is sent upstream to the supplier. This process simply repeats again and again over time to continually meet the requirements for materials, whether it’s between you and your customers or between you and your suppliers.

There are many applications of the physical kanban signals. For example, you could use containers or physical cards. There are some issues with cards though, especially if you’re not co-located with your suppliers and customers. If there’s long distances between you and them, then the cards have to be physically moved to a new location, scanned and emailed, or faxed. This can result in lost cards, which can be a big problem.

A modern invention that’s working extremely well is the e-Kanban system. How it works is, in the assembly plan or production facility, as a standard amount of raw materials is consumed, a bar code or RFID can be scanned to signal a pull for more materials.

5S

5S is a discipline for creating and maintaining a clutter- free, clean, organized safe and high – performance workplace in 5 steps, which are seiri, seiton, seiso, seiketsu and shitsuke.

- Seiri – Sorting out: Clean out the work area, keeping what is necessary in the work area, relocating or discarding what is not

- Seiton – Systematic arrangement / Set limits and Locations: Arrange needed items so they are easy to find, use and return

- Seiso – Shine and Sweep: Clean and care for equipment area

- Seiketsu – Standardization: Make all work areas similar

- Shitsuke – Self-Discipline / Sustain: Make these rules natural and instinctual

Theory of Constraints (TOC)

It is a methodology for identifying the most important limiting factor (i.e. constraint) that stands in the way of achieving a goal and then systematically improving that constraint until it is no longer the limiting factor. It was first published in The Goal by Eliyahu M. Goldratt and Jeff Cox in 1984. TOC conceptually models the manufacturing system as a chain, and advocates focusing on its weakest link. Goldratt defines a five-step process that a change agent can use to strengthen the weakest link, or links, which includes

- Identify the System Constraint – The part of a system that constitutes its weakest link can be either physical or a policy.

- Decide How to Exploit the Constraint – Goldratt instructs the change agent to obtain as much capability as possible from a constraining component, without undergoing expensive changes.

- Subordinate Everything Else – The non-constraint components of the system must be adjusted to a “setting” that will enable the constraint to operate at maximum effectiveness. Once this has been done, the overall system is evaluated to determine if the constraint has shifted to another component. If the constraint has been eliminated, the change agent jumps to step five.

- Elevate the Constraint – “Elevating” the constraint refers to taking whatever action is necessary to eliminate the constraint. This step is only considered if steps two and three have not been successful. Major changes to the existing system are considered at this step.

- Return to Step One, But Beware of “Inertia”