In it the image is produced by the direct scanning of a laser beam across the printer’s photoreceptor. Xerox, Hewlett-Packard, and Canon were pioneers in developing the laser printer technology. Scientists at Xerox developed the process in 1971 and first desktop laser printer was introduced by HP in 1984.

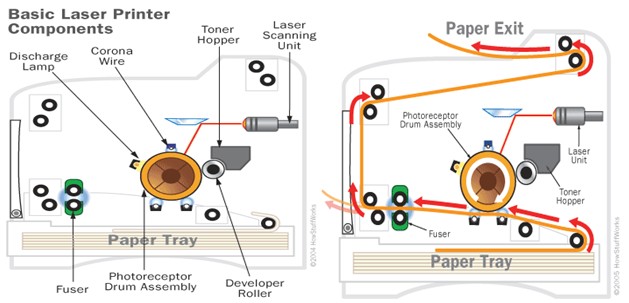

Laser Printer Parts

Laser technology consists of the toner cartridge, laser scanner, high-voltage power supply, DC

power supply, paper transport assembly (including paper-pickup rollers and paper-registration rollers), transfer corona, fusing assembly, printer controller circuitry, and ozone filter.

Toner cartridge – It holds the toner which is a black carbon substance mixed with polyester resins and iron oxide particles to make the toner attracted to the photosensitive drum and of melting into the paper. Toner also has a medium also called the carrier which carries the toner until it is used. It also has the print drum which is coated with photosensitive material to hold a static charge when not exposed to light (but cannot hold a charge when it is exposed to light). Finally, the drum contains a cleaning blade that continuously scrapes the used toner off the photosensitive drum to keep it clean.

Laser Scanning Assembly – The photosensitive drum can hold a charge if it’s not exposed to

light. Laser scanning assembly scans the laser across the photosensitive drum.

High-Voltage Power Supply – Laser printing needs high-voltage electricity. The high-voltage power supply (HVPS) provides the high voltages used during printing. This component converts house AC current (120V, and 60Hz) into higher voltages that the printer can be used to energize both the charging corona and the transfer corona.

Paper-Transport Assembly – It is responsible for moving the paper through the printer. It has a motor and many rubberized rollers like the feed roller, or paper-pickup roller which rotates against the paper and pushes paper sheet into the printer and other roller is the registration roller which synchronize the paper movement. Both rollers are operated with an electric motor called electronic stepper motor which move in very small steps and it powers all the paper-transport rollers and the fuser rollers.

Corona Assembly – It is given a high-voltage charge, which is transferred to the paper which pulls the toner from the photosensitive drum. It also has a static-charge eliminator strip to drain away the charge imparted to the paper by the corona, else paper will stick to cartridge and jam the printer. There are two types of corona assemblies: those having a corona wire and those with a corona roller. The transfer corona wire is a small diameter wire charged by the high voltage power supply and is located in the floor of the laser printer and the corona roller is a roller rather than a wire but with same function but roller supports higher speeds and corona wire is no longer used.

Fusing Assembly – The toner in the toner cartridge stick to paper because toner has a negative static charge and most objects have a net positive charge but can be removed by brushing. Fusing assembly uses two rollers to apply pressure and heat to fuse the plastic toner particles to the paper that’s why pages come out warm.

Printer Controller – It is a circuit board which converts signals from PC to signals for various assemblies in printer, using a process known as rasterizing. It is mounted under the printer and has connectors for each type of interface and cables to each assembly. When PC prints to a laser printer, it sends a signal through a cable to the printer controller which formats data into a page’s worth of line-by-line commands for the laser components and sends commands to each of the components.

Print Process

Before printing, the controller senses of printer being ready to start printing by checking presence of toner cartridge, fuser warmed, covers being in place and other checkpoints it checks before initiating the printing process.

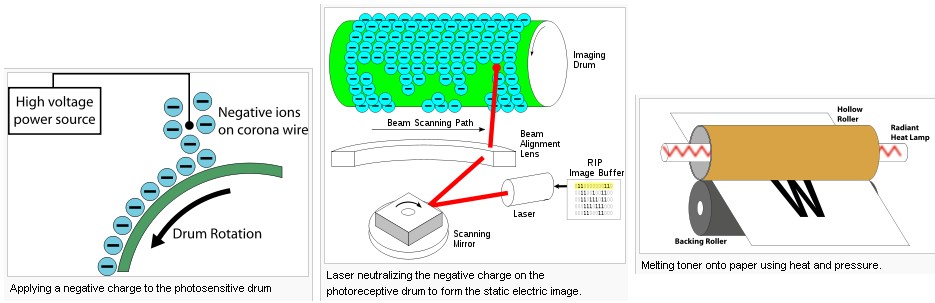

The primary principle at work in a laser printer is static electricity, the same energy that makes a lightning from cloud to ground. Objects with opposite static electricity fields are attracted to each together. Laser printer uses this principle as “temporary glue.” The main part of printer is the photoreceptor, which is a revolving drum and is made of photoconductive material that is discharged by light photons.

Initially, the drum is given a total positive charge by the charge corona wire, a wire which is running through it. (Some printers use a charged roller instead of a corona wire.) As the drum revolves, the printer shines laser beam across the surface to discharge certain points. In this way, the laser “draws” the letters and images to be printed as a pattern of electrical charges — an electrostatic image.

After the pattern is set, the printer coats the drum with positively charged toner — a fine, black powder. Since it has a positive charge, the toner clings to the negative discharged areas of the drum, but not to the positively charged “background.” This is like writing on a bottle with glue and then rolling it on flour: flour sticks only to glue-coated part of bottle.

With the powder pattern affixed, the drum rolls over a sheet of paper, which is moving along a belt below. Before the paper rolls under the drum, it is given a negative charge by the transfer corona wire (or charged roller). This charge is stronger than the negative charge of the electrostatic image, so the paper can pull the toner powder away. Since it is moving at the same speed as the drum, the paper picks up the image pattern exactly. To keep the paper from sticking to the drum, it is discharged by the corona wire immediately after picking up the toner.

Finally, the printer passes the paper through the fuser, a pair of heated rollers. As the paper passes through these rollers, the loose toner powder melts, fusing with the fibers in the paper. The fuser rolls the paper to the output tray, and you have your finished page. The fuser also heats up the paper itself, of course, which is why pages are always hot when they come out of a laser printer. The paper does not burn because the paper passes through the rollers so quickly that it doesn’t get very hot.

After depositing toner on the paper, the drum surface passes the discharge lamp. This bright light exposes the entire photoreceptor surface, erasing the electrical image. The drum surface then passes the charge corona wire, which reapplies the positive charge.

Apply for IT Support Certification

https://www.vskills.in/certification/certified-it-support-professional