Customers expect products to not only meet the specified parameters upon delivery but to function throughout what they perceive as a reasonable lifetime.

The study of reliability engineering is usually undertaken primarily to determine and improve the useful lifetime of products. Data are collected on the failure rates of components and products, including those produced by suppliers. Competitor’s products may also be subjected to reliability testing and analysis.

A needs assessment is a systematic process for determining and addressing needs, or “gaps” between current conditions and desired conditions or “wants”. The discrepancy between the current condition and wanted condition must be measured to appropriately identify the need. The need can be a desire to improve current performance or to correct a deficiency.

A needs assessment is a part of planning processes, often used for improvement in individuals, education/training, organizations, or communities. It can refine and improve a product such as a training or service a client receives. It can be an effective tool to clarify problems and identify appropriate interventions or solutions. By clearly identifying the problem, finite resources can be directed towards developing and implementing a feasible and applicable solution. Gathering appropriate and sufficient data informs the process of developing an effective product that will address the groups needs and wants. Needs assessments are only effective when they are ends-focused and provide concrete evidence that can be used to determine which of the possible means-to-the-ends are most effective and efficient for achieving the desired results.

There are three perspectives on need in a needs assessment; perceived need, expressed need and relative need.

- Perceived needs are defined by what people think about their needs, each standard changes with each respondent.

- Expressed needs are defined by the number of people who have sought help and focuses on circumstances where feelings are translated into action. A major weakness of expressed needs assumes that all people with needs seek help.

- Relative needs are concerned with equity and must consider differences in population and social pathology.

Reliability Engineering Tools

Reliability engineering tools help the design engineer work more efficiently and effectively in various ways, as various terms used are

- Mean Time Between Critical Failure (MTBCF) – The mean time between failures of mission-essential functions, calculated as the ratio of active hours (those excluding scheduled maintenance) and the number of critical failures.

- Mean Time Between Downing Events (MTBDE) – A measure calculated as the total uptime over the number of downing events.

- Mean Time Between Failure (MTBF) – The mean equipment operating time between failures of any type, calculated by dividing uptime by the total number of failures.

- Mean Time To Failure (MTTF) – A system, subsystem or device’s mean time to failure, as calculated at a specific point in time. This differs from MTBF in that it changes over time as the system is maintained.

- Mean Time To First Failure (MTTFF) – The Mean Time to Failure starting from when the system is first made to be Mission Capable.

- Mean Time to Repair (MTTR) – The total amount of time spent performing all corrective maintenance repairs divided by the total number of those repairs.

One of the most crucial reliability function is the anticipation of possible failures and the establishment of reliability acceptance goals that will limit their occurrence and consequent costs. Once component, product, and system reliability goals have been set, a testing protocol should be implemented to provide validation that these goals will impact the failure rates and the associated consequences as planned.

Reliability engineers take the long-term view and develop cost-effective ways to reduce lifecycle costs. These may range from design techniques such as redundancy and adhering to specification of manufacturing parameters such as burn-in-time. Increased reliability sometimes means increased manufacturing cost and selling price. Properly implemented, however, the result will be a decrease in lifecycle cost.

Prototyping

A prototype is an early sample, model, or release of a product built to test a concept or process or to act as a thing to be replicated or learned from. It is a term used in a variety of contexts, including semantics, design, electronics, and software programming. A prototype is designed to test and try a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one. In some workflow models, creating a prototype (a process sometimes called materialization) is the step between the formalization and the evaluation of an idea.

There is no general agreement on what constitutes a “prototype” and the word is often used interchangeably with the word “model” which can cause confusion. In general, “prototypes” fall into two basic categories:

- Proof-of-Principle Prototype (Model) (in electronics sometimes built on a breadboard). A Proof of concept prototype is used to test some aspect(s) of the intended design without attempting to exactly simulate the visual appearance, choice of materials or intended manufacturing process. Such prototypes can be used to “prove” out a potential design approach, such as range of motion, mechanics, sensors, architecture, etc. These types of models are often used to identify which design options will not work, or where further development and testing is necessary.

- Form Study Prototype (Model). This type of prototype will allow designers to explore the basic size, look and feel of a product without simulating the actual function or exact visual appearance of the product. They can help assess ergonomic factors and provide insight into visual aspects of the product’s final form.

Quality Function Deployment (QFD)

Quality Function Deployment is a method for prioritizing and translating customer inputs into designs and specifications for a product, service, and/or process. While the detail of the work involved in QFD can be both complex and exhaustive, the essentials of the QFD method are based on common-sense ideas and tools. QFD is a planning tool that relates a list of delights, wants, and needs of customers to design technical functional requirements.

With the application of QFD, possible relationships are explored between quality characteristics as expressed by customers and substitute quality requirements expressed in engineering terms. In the context of DFSS, these requirements critical-to characteristics, which include subsets such as critical-to-quality (CTQ) and critical-to-delivery (CTD). In the QFD methodology, customers define the product using their own expressions, which rarely carry any significant technical terminology. The voice of the customer can be discounted into a list of needs used later as input to a relationship diagram, which is called QFD’s house of quality.

One major advantage of a QFD is the attainment of shortest development cycle, which is gained by companies with the ability and desire to satisfy customer expectation. The other significant advantage is improvement gained in the design family of the company, resulting in increased customer satisfaction. QFD is a robust method having many variations in applications, as

- Prioritize and select improvement projects based on customer needs and current performance

- Assess a process’s or product’s performance versus competitors

- Translate customer requirements into performance measures

- Design, test, and refine new processes, products, and services

QFD uses various other methods like Voice of the Customer input to Design of Experiments, to work well. A special multidimensional matrix, also called as the “House of Quality,” is the best-known element of the QFD method. A full QFD product design project will involve a series of these matrices, translating from customer and competitive needs to detailed process specifications. QFD concept involves two core concepts, which are

The QFD Cycle – An iterative effort to develop operational designs and plans in four phases of

- Translate customer input and competitor analysis into product or service features.

- Translate product/service features into product/service specifications and measures.

- Translate product/service specifications and measures into process design features.

- Translate process design features into process performance specifications and measures.

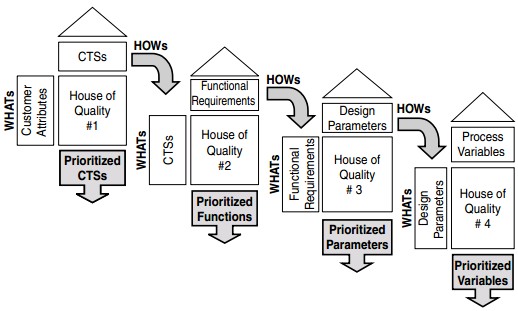

QFD is accomplished by multidisciplinary DFSS teams using a series of charts to deploy critical customer attributes throughout the phases of design development. QFD is usually deployed over four phases. The four phases are phase 1—CTS planning, phase 2—functional requirements, phase 3—design parameters planning, and phase 4—process variables planning, as shown in the figure below.

Prioritization and Correlation – Detailed analysis of the relationships among specific needs, features, requirements, and measures. Matrices like the House of Quality or the simple L-Matrix keep this analysis organized and document the rationale behind the design effort.

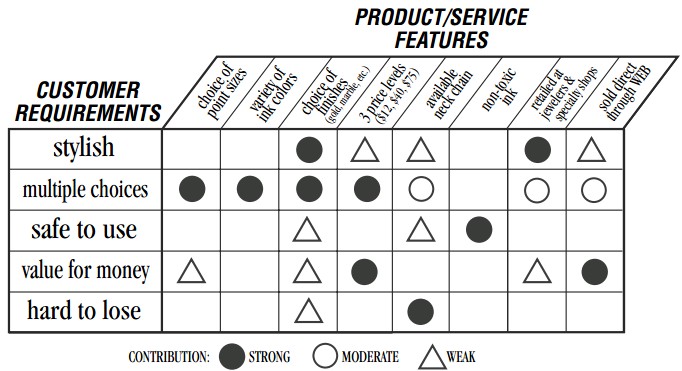

The QFD Cycle develops the links from downstream Ys (Customer Requirements and Product Specifications) back to upstream Xs (Process Specifications) in the design process itself. With an existing process or product, it can be used to clarify and document those relationships if they’ve never been investigated before. Another benefit of the House of Quality is a “diagonal” relationship test afforded by the matrix, testing combinations that may not have been considered by our standard human “linear” thought processes. An example is shown below

QFD analysis is conducted in six steps as

- It starts with the articulation of customer requirements. Techniques used could be interviewing, observation, prototyping, conceptual modeling, etc. The data from marketing research are also used. These requirements are also known as the “What’s”.

- In the second step, the company’s current product is ranked against the competitors.

- Next, the team looks at Product/Process Characteristics, in other words, the “How’s” of meeting the customer requirements. Candidate CCR’s are listed across the top and for each their relevance is considered and ranked as to which will address customer needs.

- Then, the team relates customer and technical requirements with ratings such as “high”, “moderate”, “low”, and “no” correlation. The team evaluates the degree to which customer wants and needs are addressed by the product or process characteristics.

- In the fifth step, the roof of the “House” focuses on relationships among product/process characteristics. It shows whether the “How’s” reinforce or conflict with one another.

- In last, the team summarizes the key conclusions. It ranks the relevance of product or process characteristics to the attainment of customers’ wants or needs.