Total Cost Perspective

Total logistics costs consider the whole range of costs associated with logistics, which includes transport and warehousing costs, but also inventory carrying, administration and order processing costs.

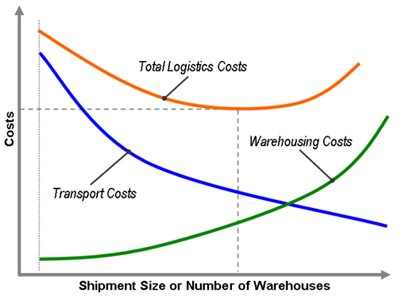

The above graph portrays a simple relationship between total logistics costs and two important components; transport and warehousing.

Based upon the growth in the shipment size (economies of scale) or the number of warehouses (lower distances) a balancing act takes place between transport costs and warehousing (inventory carrying) costs. This function differs according to the nature of freight distribution.

There is a cutting point representing the lowest total logistics costs, implying an optimal shipment size or number of warehouses for a specific freight distribution system. Finding such a balance is a common goal in logistical operations.

Trade-offs

Generally the cost trade-offs within the logistics system are assessed in two ways.

- From the point of view of their impact on total costs and

- Their impact on sales revenue.

For example it may be possible to trade-ff costs in such a way that total costs increase, yet because of the better service now being offered, sales revenue also increases. If the difference between revenue and costs is greater than before, the trade-off may be regarded as leading to an improvement in cost effectiveness.

Zero Sub-optimization

Zero Sub-optimization is a term applied to the situation in which one distribution function is optimized resulting in the impairment of another distribution function.

For example, until recently, logistics activities had one primary focus—to minimize unit transportation costs for shipments to downstream customers. To achieve a company would decide to sit on inventory in order to build a optimum transportation load and thereby obtain a lower freight rate.

This approach is okay if the accounting for the cost of inventory is not taken into consideration. But if the cost of having inventory to sit on the warehouse floor for a few more days is evaluated, the real cost of the decision will emerge.

Again trying to minimize inventory costs by maintaining significantly low inventory levels can lead to stock-outs, loss of sales, increased transportation and loss of customers. This kind of sub-optimization is a by-product of a functional orientation.

Systems Perspective (Supply Chain Management)

The systems approach is a critical concept in logistics. Logistics is, in itself, a system; it is a network of related activities with the purpose of managing the orderly flow of material and personnel within the logistics channel.

The systems approach is a simplistic yet powerful paradigm for understanding interrelationships. The systems approach simply states that all functions or activities need to be understood in terms of how they affect, and are affected by, other elements and activities with which they interact. The idea is that if one looks at actions in isolation, he or she will not understand the big picture or how such actions affect or are affected by, other activities. In essence, the sum of outcome of a series of activities is greater than its individual parts.

The systems approach is key to understanding the role of logistics in the economy, its role in the organization, including its interface with marketing, the total cost concept, and logistics strategy.