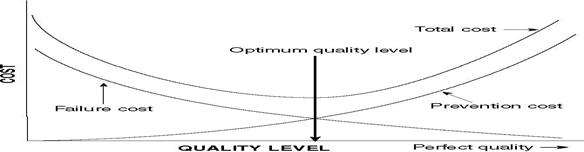

The “cost of quality” isn’t the price of creating a quality product or service. It’s the cost of not creating a quality product or service. Every time work is redone, the cost of quality increases. Cost of quality is the sum of various costs as that of appraisal costs, prevention costs, external failure costs, and internal failure costs. It is generally believed that investing in prevention of failure will decrease the cost of quality as failure costs and appraisal costs will be reduced. Understanding cost of quality helps organizations to develop quality conformance as a useful strategic business tool that improves their product, services & brand image. This is vital in achieving the objectives of a successful organisation.

COQ is primarily used to understand, analyze & improve the quality performance. COQ can be used by shop floor personnel as well as a management measure. It can also be used as a standard measure to study an organization’s performance vis-à-vis another similar organisation and can be used as a benchmarking indices.

Various types of Quality Costs are

Appraisal Costs: The costs associated with measuring, evaluating or auditing products or services to assure conformance to quality standards and performance requirements. These include the costs of

- Inspection of software requirements

- In-process and final inspection

- Product and process audits

Prevention costs: Prevention Costs are any costs that are incurred in an effort to minimize appraisal and failure costs. This category is where most quality professionals want to live. They say an ounce of prevention is worth a pound of cure and they are what this category is all about. This includes the activities that contribute to creation of the overall quality plan and the numerous specialized plans. Examples are costs associated with Quality planning, formal technical reviews, test equipment, training.

Failure costs: The costs resulting from products or services not conforming to requirements or customer/user needs. Failure costs are divided into internal and external failure categories.

- Internal failure costs: Incurred when an error is detected in a product prior to shipment; Include rework, repair, and failure mode analysis

- External failure costs: Involves defects found after the product has been shipped

- Include complaint resolution, product return and replacement, help line support, and warranty work.

Examples of the various costs are

- Prevention – Training Programme, Preventive Maintenance

- Appraisal – Depreciation of Test/ Measuring Equipment, Inspection Contracts

- Internal Failure – Scrap, Rework, Downtime, Overtime

- External Failure – Warranty, Allowances, Customer Returns, Customer Complaints, Product Liability, Lawsuits, Lost Sales

Identifying COQ can have several benefits, as

- It provides a standard measure across the organisation & also inter-organisation

- It builds awareness of the importance of quality

- It identifies improvement opportunities

- Being a cost measure, it is useful at shop floor as well as at management level