Logistics management is the part of supply chain management that plans, implements, and controls the efficient, effective forward, and reverse flow and storage of goods, services, and related information between the point of origin and the point of consumption in order to meet customer’s requirements.

The appreciation of the scope and importance of logistics and the supply chain has led to a more scientific approach being adopted towards the subject. This approach has been aimed at the overall concept of the logistics function as a whole and also at the individual sub-systems. Much of this approach has addressed the need for, and means of, planning logistics and the supply chain, but has also considered some of the major operational issues.

According to the Council of Logistics Management, logistics contains the integrated planning, control, realization, and monitoring of all internal and network-wide material-, part- and product flow including the necessary information flow in industrial and trading companies along the complete value-added chain (and product life cycle) for the purpose of conforming to customer requirements.

Logistics is the art and science of managing and controlling the flow of goods, energy, information and other resources. (Wikipedia, 2006)

Logistics management is the planning, implementation and control of the efficient, effective forward and reverse flow and storage of goods, services and related information between the point of origin and the point of consumption in order to meet customer requirements. (CSCMP, 2006)

Parallel to the growth in the importance of distribution, logistics and the supply chain has been the growth in the number of associated names and different definitions that are used. Some of the different names that have been applied to distribution and logistics include

- physical distribution;

- logistics;

- business logistics;

- materials management;

- procurement and supply;

- product flow;

- marketing logistics;

- supply chain management;

- demand chain management;

- and there are several more.

Logistics is a diverse and dynamic function that has to be flexible and has to change according to the various constraints and demands imposed upon it and with respect to the environment in which it works.

These many terms are used, often interchangeably, in literature and in the business world. One quite widely accepted definition that uses some of these terms also helps to describe one of the key relationships. This is as follows

Logistics = Materials management + Distribution

Major emphasis is now placed on the importance of information as well as physical flows and storage, and an additional and very relevant factor is that of reverse logistics – the flow of used products and returnable packaging back through the system.

It is interesting to detect the different biases – military, economic, academic, etc. An appropriate modern definition that applies to most industry might be that logistics concerns the efficient transfer of goods from the source of supply through the place of manufacture to the point of consumption in a cost-effective way whilst providing an acceptable service to the customer.

Logistics Role and 7R’s

Logistics and the supply chain finally became recognized as an area that was key to overall business success. Indeed, for many organizations, changes in logistics have provided the catalyst for major enhancements to their business. Leading organizations recognized that there was a positive ‘value added’ role that logistics could offer, rather than the traditional view that the various functions within logistics were merely a cost burden that had to be minimized regardless of any other implications.

Thus, the role and importance of logistics continued to be recognized as a key enabler for business improvement.

The purpose of logistics is to plan, organize, coordinate, and implement the bridging of the dimensions of time and space within a system. Logistics is thus one of the most important functions of the economy. This ranges from the procurement of raw materials to their processing and to the delivery of the goods to the end-user.

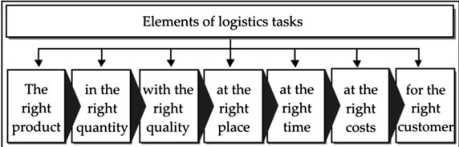

The central tasks of logistics can be graphically described by the so-called seven R’s, as depicted in figure below

There are not any clear-cut definitions as to what constitutes right. The right thing to do always individually results from the particular elements involved in the logistical task, i.e. from the products, the quantity, the spatial relations, the customer requirements etc.

Logistics of Services

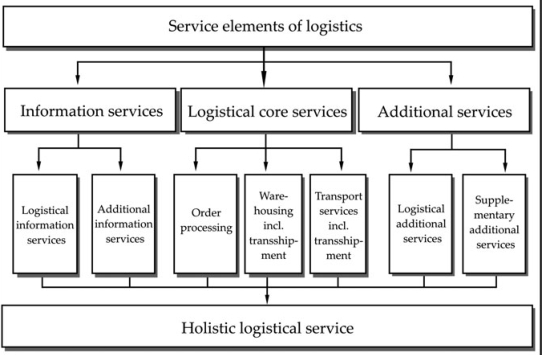

The logistical system of services features a wide range of system components, which are illustrated in figure below

The core services of logistics, such as order processing, storage and transport, are directly supported by the logistical information services and the additional services necessary for the logistics process. In practice, the element of transshipment is rarely dealt with separately since it is usually closely connected to storage and transport. The core element of order processing is some-what virtual in nature but constitutes an indispensable element for the initiation and monitoring of logistics processes. It is the order processing which gives logistics its dynamic character. Order processing comprises the processing and monitoring of the order data from the time of order until the arrival of the goods at the customer’s site and of the return of the shipment documents. In many cases this includes the initiation of invoicing processes, e.g. by simultaneously delivering the invoice together with the goods.

The core element of storage denotes the warehousing of goods, which have mostly been produced for an anonymous market to offset the quantitative and chronological divergence of production (supply) and sales (demand). It has to be noted at this point that the functions of picking and packing, which are closely connected to the core element of storage, fall into the category of additional services. Picking means the compilation of sellable articles according to individual customer orders to form package and shipping units.

Finally, the core function of transport bridges the spatial distance from the site of production to the storage location to the delivery location at the customer’s site. Thus, it offsets the spatial divergence of supply and demand. Again it has to be pointed out that both storage and transport include the function of transshipment. Logistical information services produce and utilize data about the goods being transported within the logistics system. This data includes information about the forwarder, the recipient, the type of goods, order number, quantity, weight, volume etc. The logistical information is the key to planning, monitoring and supervising the provision of the actual logistics service. A data-driven logistical activity closely connected to the core service of storage is the inventory management.

Additional services of logistics include, for instance, picking, palletizing of goods for economical shipping (easier loading and transport), additional packaging for protection, identification and easier handling of goods and commodities, repackaging of goods from bulk packaging into smaller package units etc. Supplementary information services and additional services can usually be incorporated into the logistical core process without expanding further organizational effort. In this way, substantial additional value can occasionally be created for the contractor of the logistical service.

Case Study: Module Assembly – BMG (a module assembly company) is a fully owned subsidiary of the logistics provider Schnellecke. BMG has been entrusted by Volkswagen Braunschweig with the assembly of the modules Subframe and Cornermodule, pertaining to the car models Golf and Passat, for Volkswagen Sachsen Ltd. in Zwickau [additional service]. The service provider is also responsible for the disposition and storage of the primary material [logistical core service] and for the delivery of the assembled modules to the assembly line [logistical core service]. The assembly and delivery for each particular production sequence is carried out according to the logistics planning of Volkswagen Sachsen Ltd