Lot Size Reorder Point Policy

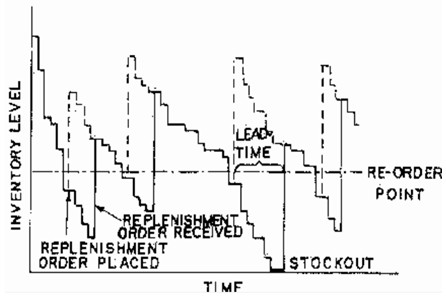

Under this operating policy the inventory status is continuously reviewed and as soon as the inventory level falls to a prescribed value called `Reorder Point’. A fresh replenishment order of fixed quantity called Economic Order Quantity (EOQ) is initiated. Thus the order size is constant and is economically determined. This is one of the very classical types of inventory policies and a lot of mathematical analysis has appeared on this type of policy. Figure I show the typical stock balance under this type of inventory policy. The solid line in this figure represents the actual inventory held in practical situation with a finite lead time, the lead time being defined as the time delay between the placing of a replenishment order and its subsequent receipt. The broken line indicates the inventory that would be held in the ideal situation if no lead time existed. Lot size and reorder point are the two decision variables involved in the design of the policy.

Figure 1: Typical Inventory Balances for EOQ- Reorder Point Policy

Fixed Order Interval Scheduling Policy

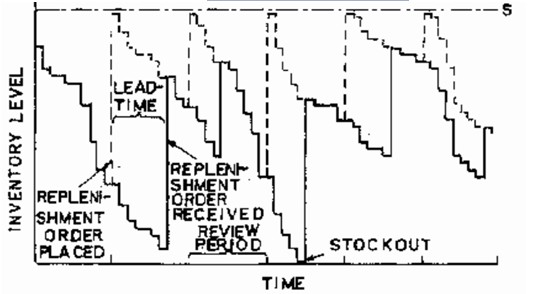

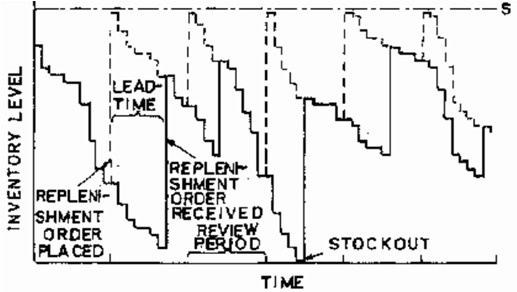

Under this policy the time between the consecutive replenishment orders is constant. There is a maximum stock level(s) prescribed and the inventory status is reviewed periodically with a fixed interval (T). At each review an order of size Q is placed which takes the stock on hand plus an order equal to the maximum stock level. Thus order quantity could vary from period to period. This policy ensures that when the level of stock on hand is high at review, a smaller size replenishment order is placed. Figure II shows the typical stock balances under this fixed reorder cycle policy. S, the maximum stock level and T the review period are the decision variables under this policy.

Figure II: Fixed Reorder Cycle Policy

Fixed Order Interval Scheduling Policy

Under this policy the time between the consecutive replenishment orders is constant. There is a maximum stock level(s) prescribed and the inventory status is reviewed periodically with a fixed interval (T). At each review an order of size Q is placed which takes the stock on hand plus an order equal to the maximum stock level. Thus order quantity could vary from period to period. This policy ensures that when the level of stock on hand is high at review, a smaller size replenishment order is placed. Figure II shows the typical stock balances under this fixed reorder cycle policy. S, the maximum stock level and T the review period are the decision variables under this policy.

Figure II: Fixed Reorder Cycle Policy

Optional Replenishment Policy

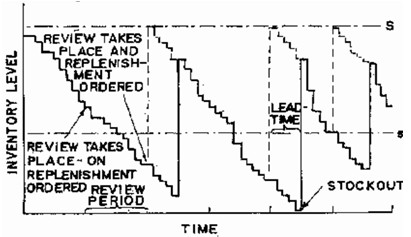

This is very popularly known as the (s, S) policy. Figure III shows the typical stock balance under this policy. The status of stock is periodically reviewed and maximum stock level (S) and minimum stock level (s) are prescribed.

Figure III: Typical Inventory Balances in (A, S) Policy

If at the time of review, the stock on hand, is less than or equal to s, an order of size Q is placed so that stock on hand plus on order equals the maximum stock level S. If stock on hand at review is higher than s, no order is placed and the situation is reviewed at the time of next review period. S, s and T (review period) are the decision variables in the design of such inventory policy

Other Types of Inventory Systems

There may be other policies which may be special cases of the policies mentioned above or may be a combination of these policies. As a special case of (s, S) policy we may have (S-1, S) policy or one-for-one order policy when the maximum stock level may be up to S and whenever there is demand for one unit, a replenishment of one unit is ordered. Such a policy may be quite useful for slow moving expensive items. We may use a combination of lot size reorder point policy and fixed interval order scheduling policy. Yet another variation of inventory policy could be multiple reorder point policy where more than one reorder point may be established.

Other types of inventory systems may be static inventory systems when a single purchase decision is to be made which should be adequate during the entire project duration. Such decisions are not repetitive in nature. Other initial provisioning decisions may be with respect to repairable assemblies such as engines, gearboxes etc. in a bus which may have to be overhauled and for which we have to find adequate number of spare engines to be provided initially.

The right choice of an inventory policy depends upon the nature of the problem usage value of an item and other situational parameters. We must first select an operating policy before determining optimal values of its parameters.