Introduction: Bellop Ltd. established in the early 1960s as a private firm, is manufacturing a number of electronic equipment items. The organization, being a fairly large one, is a pioneer in the range of products manufactured by it. The technological excellence of its products has gained it a place among organizations, which undertake complex design development work for the electronic industry as a whole. During the late eighties, the company established a unit within its present manufacturing premises, exclusively dedicated to such developmental tasks. The unit was organized to produce fabricated components on the cellular manufacturing principle.

Currently, its fabrication shop is divided into five work cells. These cells are, more or less, divided on the basis of operation layouts for components. Each cell processes a group of similar products, due to which, flexibility and economy are achieved in manufacturing. Approximately 50 to 70 percent of mechanical parts go through the paint shop to the assembly; hence, the importance of the paint shops. The present trend indicates that about 70 percent of the load in the paint shop is due to jobs related to PRC and RRA projects. The work cell sequence is maintained for all the jobs but some operations may be skipped depending upon the, routing of a job. More details about various operations in their sequence for the jobs of the particular month studied are given in Table 7.2.

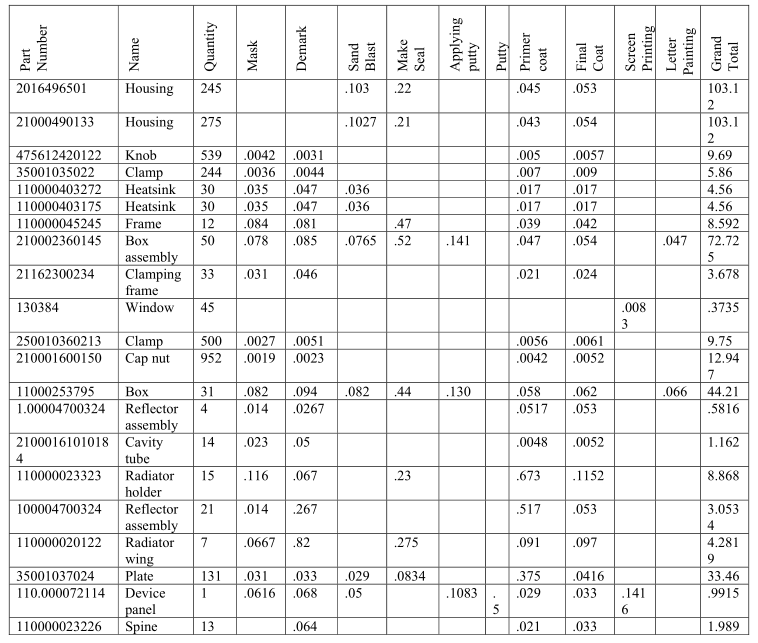

Table 7.2 Sequence of Operations for Jobs

The paint shop can be considered as a job shop inputs coming in batches of different quantities and of different types at different points in time. Yearly forecast / order booking is done by the Sales Department. The forecast gives an idea 0 how many jobs per project are to be processed during the current year. It includes any backlog 0 the previous orders as well. This forecast is considered by various project cells so as to make quarterly schedule for the number of jobs. There are five project cells which monitor the progress of various jobs produced against their requirements. These cells expedite the production in the pair shop on the basis of assembly requirements.

The job plan is divided into the categories.

- Monthly production.

- Quarterly production.

- Yearly production

The quarterly plan is broken into a monthly plan or monthly list for the parts to be delivered (which are in short supply) for the assembly requirements.

Except for RRA accessories and some critical parts of the project, due dates are generally not fixed. There is a senior planning officer whose function is to coordinate the shop floor planning and project cells. Based on his advice, the priority of urgent jobs is fixed. Once a week, the production progress for each project is reviewed by the work cells, project cells and the senior planning officer and corrective actions are decided upon.

At the overall operating level, the control is applied through a weekly review of production. Weekly production is monitored by the respective project cells. The general experience of the planning group is that, urgent jobs are always in large numbers. This leads to the disturbance of the normal operation of the production shop and consequently, the equipment utilization suffers. The shop is controlled by a shop planning cell in coordination with an assistant works manager. The shop gets a monthly open shop order for various jobs. The first batch may be a partial one. If it is a partial batch, then the rest of the batch arrives the next time. But this arrival is random. After getting the priority of a job from the project cell, the daily priority of a job order is fixed and it is launched. No completion time of the job is specified on the job order. It is solely dependent upon the discretion of the shop supervisor, who determines the quantity and what jobs are to be loaded together with the jobs with higher priority

Existing Control Procedure: The only method of controlling the system is to monitor the operations and to expedite the jobs which are urgent. Since work standardization has not been done, a due date for the completion of an operation is only tentative and how much time is required for it is decided by the workman himself.

Uttampad, the manager of the development division, was facing considerable problems of undergoing delays taking place in the paint shop, which caused heavy rescheduling of assemblies and failure in delivery date commitments; He discussed his problem with the deputy manager (finishing), Anandan, the senior planning officer, Shankar and the superintendent of paint shop, Vora. The following were the main contentions.

Anandan felt that if they compared the overall operating system with an ideal system, deficiencies were very many. Shankar, however, felt that a specific schedule had to be made, giving due dates for the completion of the operations so as to minimize the avoidable delay and determine the point of delay in the production process. By giving due dates, a higher level of control over the entire production could be achieved, because some techniques like the critical ration decision rule could be used to determine the priorities automatically. It would also minimize the effect of passing of the buck in respect of delays. A higher number of rush orders reflected a poor system that was existing.

Uttampad, however, felt that if due dates could not be given a priority, then obey would have to settle for some sort of loading of facilities with jobs, according to some dynamic priority criterion over very short intervals to utilize the capacity as fully as possible. But the paint shop superintendent, Vora, felt that the capacity of the paint shop was inadequate for the load coming on it. He wanted Khan, the industrial engineering supervisor, to correctly assess the capacity of the shop and submit a report. In his opinion, the capacity was increased, the scheduling procedures, which Shankar felt were required would be of no ask Walker, a young management graduate student (who had approached him for arranging him a project study for his degree) to study the shop and develop a scheduling procedure.

Khan made a snap work sampling study and discussed with the supervisors in the paint and finishing shops. He submitted the following report.

Khan’s Report: For analyzing the existing problems, first a snap work sampling was carried out to estimate the required capacity utilization (see Appendix to report). Then the existing paint shop was studied thoroughly. The paint shop studied could be considered as a batch type production system. The main features of the shop were:

- Intermittent and random arrival of jobs

- Different types of jobs

- Wholly manual operation.

Load and capacity were estimated in man-hour units. Load was defined as the man-hours required performing an operation at normal pace. The total load was obtained as the summation of various loads. Capacity was defined as the potential time available for work, at a work centre expressed in man-hours. For the purposes of calculation of capacity, various allowances like personal time, cleaning work station, shutdown, tool maintenance and unavoidable delays were also considered.

A load factor of 0.7 was used because only two projects were considered. Absenteeism and lunch or tea breaks were also considered in determining the capacity.

Estimation of Available Capacity:

- Net capacity for various operations is calculated as shown below

- Net capacity available per shift was calculated using the formula

- Net capacity /shift in man-hours= available hours shift x allowance factor

- x absenteeism factor x load factor

Further, it was decided to estimate the representative time per part. Based on observations, the times for different operations and their averages were computed depending on the type of job and operations. Proper allowances (fatigue, personal and others) were added to these on the basis of the standards prescribed by the International Labor Organization (ILO). In arriving at these timings the views of the workers themselves and the shop supervisions were given due weightings. Acceptance of these times by the workers facilitated their use in short interval scheduling (SIS)

Since it was not possible to observe the operations of the all the parts, Khan decided to_ extrapolate the time per operation for the remaining parts on the basis of representative parts of that category. It was assumed after discussion with the management, that a measure of the painting time could be taken as proportional to the painted area. After estimating the average time per operation for all the jobs in a month it was added up for different operations and the total load in terms of man-hours was calculated.

Capacity Utilization: The load cleared (in man-hours) for the month in the study was as follows;

Stenciling 15.49

Sand blasting 168.19

Painting 281.80

Screen printing 33.55

Sub-total 499.03

Other manual operations 818.94

Total 1317.97

Standard man-hours available = 3173.8 for the month.

Therefore,

Overall capacity utilization = 1317.9/3173.8

= 41.5%

This was comparable to the work sampling results. As compared to this, the load for the next month (in man-hours) was as follows:

Estimated for the next month

Painting 178.66

Stenciling 11.15

Screen printing 4.02

Sand blasting 35.71

Manual 673.26

The expected load capacity rations were as follows:

Painting 175/209.83=0.83

Stenciling 11.2/141.68=.079

Screen printing 35.70/141.6=0.25

Sand blasting 4.0/70.5= 0.05

Manual 673.3/1039=0.64

Therefore, the painting and manual operations were the bottleneck in the system and an extra paint booth might be required if the capacity utilization as low as in the previous months. But due to the flexible nature of manual operations, man-power could be diverted to manual work from stenciling, sand blasting and screen printing booths, and this had to be exploited in the development of any algorithm for scheduling of jobs in the paints shop.

Walker‘s Report on the Proposed Scheduling Procedure: Similarly, Walker the management graduate student studied the shop along with Khan for about one and half months and submitted a report to Uttampad as given in the following Appendix.

Appendix to Khan’s Report

Details of work sampling:

Total number of observations = 98

Total number of observations when paint

Booths were used = 20

Total number of observations when sand

Blasting booths were used = 7

Total number of observations when stenciling

Booths were used = 21

Total number of observations when

Screen painting was done = 7

(i) Utilization of point booth = 20/98

=20.4%

(ii) Utilization of sand blasting booth = 7/98

= 7.14%

(iii) Utilization of stenciling booth = 21/98

= 21.4%

(iv) Utilization of screen painting fixture = 7/98

= 7.14%

Note: For the purposes of calculating the number of observations, the following formula was use<1

b=fx, op (1-p/n) where

h =+or-1O%

1 = 1.96 for 90% confidence interval with normal distribution

Ip= 0.4, i.e. the utilization is 40%

One of the problems of scheduling or controlling in the job shop under consideration is the requirement of data on the status of the system. An associated problem is that such data pertaining to the production system may not be available. Thus, many decisions are to be based on insufficient data. Another problem is to develop a scheduling procedure which works in practice. There are two phases of controlling an intermittent job shop. The first phase is loading and the second is scheduling.

Loading: A load is the amount of work assigned to a facility and loading is the assignment of work to a facility. A chart can tell us in advance whether there is an overload or under load. Loading can be used to smooth the work load in small scheduling periods. For loading effectively information is required on the following points:

- The work assignment.

- The work content of the assignments 3. Notice of assignment completion

In the present study, work assignment was first determined. From the part production progresses and project process chart, the number and type of parts coming for the processing in the paint shop were obtained. Since the work content was not given full in the operation analysis and routing chart, it W2 is estimated with the help of shop supervisors. For example, the operation and routing chart does not_ say whether the putty is to be applied or not, how standardization of the operations and labor force. Therefore, the times for the operation were estimated on the basis of a number of observations and extrapolation to various other parts for which personal observations were not possible. By aggregation the total work content for a particular month was calculated.

The required date of completion of a part was not normally given a priority by the management. There was only a part planning system in the operation on the basis of monthly loading. Therefore, it was not possible to know in advance as to when a particular part would be required from the paint shop. Therefore, the capacity was estimated for the paint shop on the basis of a work study and the standard times of fabrication shop

Scheduling, on the other hand, can smoothen the production, minimize the inventories, shorten the lead times and eliminate bottlenecks. Since the scheduling in the time-phasing of a job, the time of its starting is required. There are various scheduling techniques applicable is the case of intermittent job shops. Priority scheduling approaches, such as shortest processing time, minimum operations etc., could not be employed because the operation times were not accurately known. Therefore, it was decided to use the available ‘man-power effectively and to improve the process time of the jobs. Thus, for this purpose, short interval scheduling (SIS) was considered the most suitable approach.

Short Interval Scheduling: The main characteristic of the approach is the short interval used to describe the work activities or operations. The usual time interval is in hours and tenths of an hour. The work to be assigned to one man is broken down into a series of short tasks to which reasonable times are assigned. The overall time for the job is the summation of SIS times assigned. The operations are assumed to be steady and at average pace. The emphasis is on the minimization of idle time. Using the SIS in its best sense, the worker should perform at or near the peak efficiency with a minimum of breaks. Thus is can optimize the performance of the point shop alone by keeping in mind the various constraints.

Workers were assigned specific jobs. Estimated times were used in SIS in order to reduce the amount of sequential mental planning required of the operator. To be fair to the workers, maximizing communication between the shop superintendent and the workers was recommended.

As a first step in establishing SIS, an operation or an occurrences sheet was prepared in which operations were listed in sequential order. After this, various data required under each source and control unit information were listed (the control unit is ‘the operations unit of production, which lists components, assemblies, drawings and other reference materials, the frequencies of operations and the times required for each operation). These were taken from historical data. In establishing times for each operation, contact between the foreman and workers had to be encouraged.

During the initial implementation there might be below par performance due to orientation in requirements. For this reason, the missed schedule report is recommended. It records all the assignments not completed in time. The key section is the column headed ‘corrective action’. In this column, the scheduler notes why the schedule was not met and what corrective action was taken. A daily or weekly performance report can also be prepared. This is similar to the missed schedule report but can also report routine or better performance. A daily performance report can be made on an individual basis while the weekly report can be made on departmental basis.

Since the operations were not standardized, this method which seems quite reasonable in the present context could not be recommended in its entirety. Therefore, only its concept was used in developing a scheduling algorithm.

The Algorithm: Having considered various available techniques, it was clear that none of them could be used in total to schedule the jobs in the paint shop. Therefore, it was decided to make a combination of these to provide a new approach in scheduling the paint shop on daily basis. An algorithm was developed to suit the present system of operation.

The algorithm is developed with the objective of using the manpower effectively, and maintaining the priority of the jobs. Scheduling of the paint shop should be done in entirely and it should not disturb the overall system.

The algorithm takes the following information as input and gives job operations personnel allocation as the output, while maintaining the priorities:

- Priority list of the jobs with specified quantity per order

- Persons available and their capability of performing an operation

- Constraints on the number of persons due to non-availability of facilities

- Hours available per shift

The algorithm has the following constraints:

- At any instance of time, at the most three paints booths or two sand blasting booths or one screen printing fixture will be in operation.

- The operation sequence cannot be altered and is to be strictly adhered to.

- Partial batch processing is not permitted.

- Partial operation is not possible.

- An incomplete batch will be given its due priority in the next shift. Whenever an operation is allocated to different workmen they would start the work simultaneously.

Assumptions: The following assumptions are made in developing the present algorithm.

- The shop supervisor will be given a specific priority list.

- The required batch quantity will be known in advance.

- There will be no delay for want of instruction.

- Material movement times will be negligible.