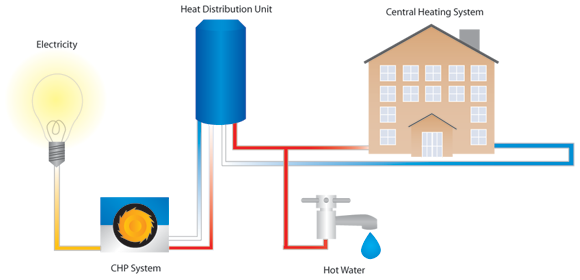

Biomass fuels are typically used most efficiently and beneficially when generating both power and heat through a Combined Heat and Power (or Cogeneration) system. A typical CHP system provides

- Distributed generation of electrical and/or mechanical power.

- Waste-heat recovery for heating, cooling, or process applications.

- Seamless system integration for a variety of technologies, thermal applications, and fuel types into existing building infrastructure.

CHP systems consist of a number of individual components—prime mover (heat engine), generator, heat recovery, and electrical interconnection—configured into an integrated whole. The type of equipment that drives the overall system (i.e., the prime mover) typically identifies the CHP unit.

Prime movers for CHP units include reciprocating engines, combustion or gas turbines, steam turbines, microturbines, and fuel cells. These prime movers are capable of burning a variety of fuels, including natural gas, coal, oil, and alternative fuels to produce shaft power or mechanical energy.

A biomass-fueled Combined Heat and Power installation is an integrated power system comprised of three major components

- Biomass receiving and feedstock preparation.

- Energy conversion – Conversion of the biomass into steam for direct combustion systems or into biogas for the gasification systems.

- Power and heat production – Conversion of the steam or syngas or biogas into electric power and process steam or hot water