Transportation confers ‘time utility’ and ‘place utility’ to the product; it determines the company’s customer service; it also has a crucial bearing on the other elements of physical distribution and marketing, like warehousing, inventory control and channel management. Finally, transportation is also a very important cost element in most businesses.

Main Tasks in Transportation Management

- Main Tasks in Transportation Management

- Assessment of the transportation requirement

- Choosing the ‘mix’ of transport modes

- Deciding the routing

- Development of operational plans

- Implementation/review

- Control of transportation costs

Basically transportation management involves decisions on:

- How much to move?

- When to move?

- Where to move?

- By what mode, or combination of modes to move?

The considerations in making these decisions are:

- The lead time for stock replenishment

- Sales expected in the territory in the intervening time

- The normal cycles of inventory build up at the warehouse/ dealer points.

If a firm can estimate these factors fairly accurately, it can make the basic decisions on transportation. In a fundamental sense, transportation has to be based on the sales forecast. Decisions on when to move, how much to move and where to move will essentially depend on the sales forecast

In the first place, a transport manager makes an assessment of the transportation requirements based on the sales forecast, sales plan and schedules. He also watches the actual sales performance vis-a-vas the forecast and updates the transportation.

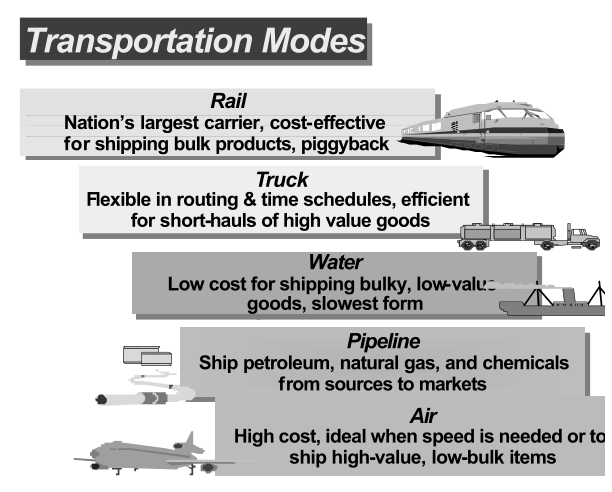

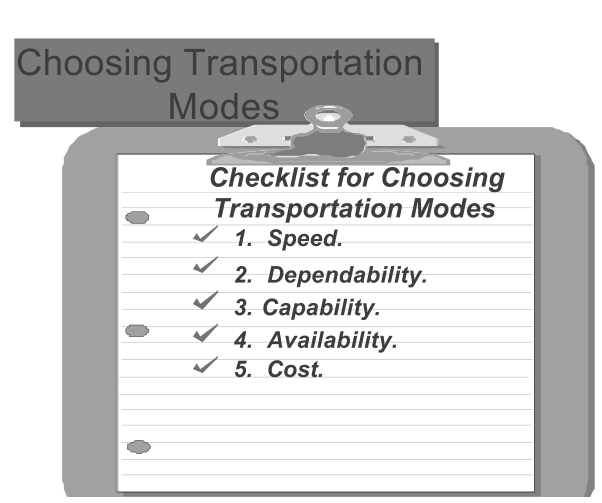

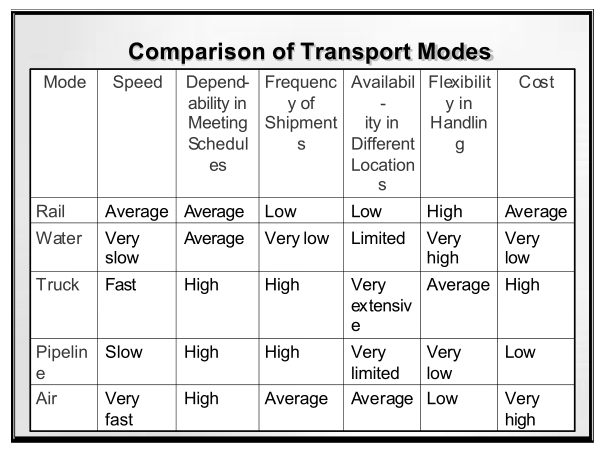

Mix of Transport Modes Depending on the product, the market and the cost factors, firms select the transport mode, or the combination/’mix’ of modes. The name of the game is optimization. A number of considerations, as listed below, are involved in the determination of the optimal mix of modes:

- How do the different modes compare in ‘speed’ and ‘costs’?

- What is the extent of ‘user orientation’ of the modes?

- What is the ‘availability’ of the modes? Is it adequate? Is it timely?

Routing has two dimensions: First, systematic assignment of territories to each production/supply point; Second, the actual sequence in which a delivery vehicle should move and service the retail points. When a firm has more than one production location or supply point, it should clearly demarcate the marketing territory to be serviced by each location. Similarly, for each warehouse/stock point too, it should demarcate the territory. Transportation effectiveness depends very much on systematic assigning of territories to each source. When there is a strong need for drawing supplies from a source other than the designated one, it can be done, but only on the basis of strong justification.

Secondly, equal care should be taken in deciding the actual sequence a delivery vehicle should take in supplying stocks to the various retail points that come under its service territory. Intelligent routing, covering both the above aspects, is an integral part of effective transportation. Optimization of transport lead, reduction of transport time and optimization of costs are the objectives in effective routing.

Developing Operational Plans: The transport manager must work out detailed operational plans from the overall transportation plan. Detailed plans/ schedules must be developed for each product and each supply point/warehouse, month-by-month and week-by-week. The plans must indicate the made/combinations of modes. They must also be properly dovetailed with the warehouse plans. Once the plan in all its details is ready, the task becomes one of creating the required transportation capacity and securing the required linkage between transportation schedules and wan house space procurement.

Implementation of Plans: The transportation job does not end with the preparation of plans, the determination of optimal modal mix, development of operational plans and putting in place the required service contracts. In fact, it begins there. The smooth movement of the product and efficient execution of the whole plan, with minimum deviation, is the real task. Many practical problems may crop up in the process. Sometimes, transport capabilities do not become available for executing the plan. Often, the rates overshoot the budgeted figures. Due to seasonal factors and pulls from competing products, which can afford to pay a higher rate, securing effective transport capacity becomes difficult. Factors like climate, road condition, labour situation, octroi rules and problems of interstate movement all affect the availability.

Controlling Transportation Costs As mentioned earlier, transport cost is a major element of distribution costs in most businesses, and it has been increasing constantly in recent years. As such, it is essential that the transportation costs are controlled tightly. Also, this has to be done without sacrificing the minimum guaranteed distribution service level to the channel and consumers. Saving in transportation can be realized by: (a) optimizing the mix of the transport modes, (b) reducing the transport lead and the lead-time through effective routing and other means, and (c) eliminating multiple and wasteful transfer, and handling of products. The transport controller has to have an overall appreciation of the whole range of physical distribution activities and the costs thereof. He cannot remain confined to the narrow role of freight rate negotiator, or a transport liaison man. He has to view transport as a total back-up capability, supporting the marketing function and a source of competitive advantage for the firm in the marketplace.