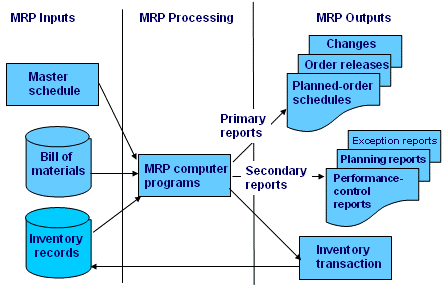

Let’s learn more about MRP and MRP II. With the help of information retrieved from the bill of materials, master schedule and inventory records file, the MRP system indicates the total requirement for raw materials, parts and components, and subassemblies against each period on the planning sphere. At first, MRP processing determines gross material requirements, then deducts the inventory in hand, and adds it back to the safety stock, for the computation of net requirements.

The MRP outputs can be in the form of primary reports as well as secondary reports. There are three kinds of primary reports, viz. planned order schedules, order releases and changes to planned orders. Planned order schedules delineate the quantity as well as timing of future material orders. Order releases give authorizations on orders to be made. Changes to planned orders may include revisions or cancellations of the time frame or quantity. On the other hand, secondary reports of MRP can also be of three kinds, viz. performance control reports, planning reports and exception reports. Performance control reports are used to keep a track of problems, such as delivery dates and stock outs that have been missed out, in order to assess system performance. Planning reports are used to forecast future inventory requirements. Exception reports are used to divert the attention of managers toward key issues such as late orders, excessive scrap rates, etc. Though working on a backward direction from the production plan to get a finished product to understand the component requirements appears a simple process, it can indeed be extremely complex, particularly in the event of raw materials being used for a variety of different products. Matters can become further complicated in product design, order quantities and production schedule. The significance of computer power is apparent when the number of material schedules that need to be tracked is considered.

MRP II

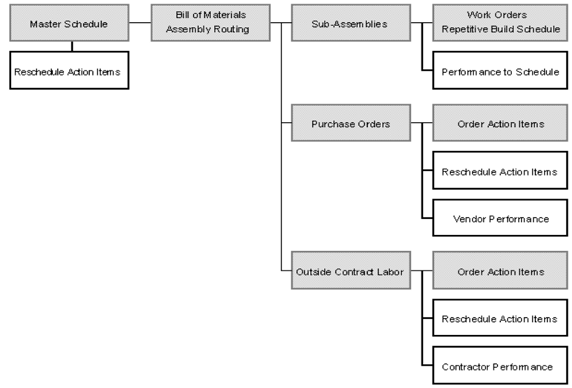

During the 80s era, the MRP technology was enhanced to formulate a new approach, known as MRP (Manufacturing Resource Planning) II that encompassed techniques to facilitate providing valid production schedules that further enables better planning and control of other resources. Often the areas of finance, marketing and human resources get affected by any improvements in customer delivery commitments, HR management projections and cash flow projects. The invention of MRP II has not replaced MRP, or is an improved version of MRP, but it does expand the scope of production resource planning and engages other functional areas, such as finance, marketing, purchase, HR and engineering, in the planning stage of an organization. In MRP II, the functional areas are inputs to the master production schedule. With this, MRP generates material requirements through which production managers plan the capacity. MRP II systems generally consist of simulation capabilities for the managers to be able to assess alternate options.

In the MRP II (or MRP2) concept, fluctuations in forecast data are taken into account by including simulation of the master production schedule, thus creating a long-term control. A more general feature of MRP2 is its extension to purchasing, to marketing and to finance (integration of all the function of the company), ERP has been the next step.

Manufacturing Resource Planning (MRP II) is an integrated information system used by businesses. Manufacturing Resource Planning (MRP II) evolved from early Materials Requirement Planning (MRP) systems by including the integration of additional data, such as employee and financial needs. The system is designed to centralize, integrate and process information for effective decision making in scheduling, design engineering, inventory management and cost control in manufacturing.

Manufacturing resource planning (MRP II) is an integrated method of operational and financial planning for manufacturing companies. MRP II serves as an extension of MRP (closed loop manufacturing resource planning, also abbreviated as CLMRP).

The typical MRP II system employs a modular organizational structure. Modules keep track of, and regulate, specific characteristics and functions of the entire organization. Examples include, but are not limited to, the following:

- Product design

- Product specifications

- QC (quality control)

- QA (quality assurance)

- Shop floor control

- Order management

- Purchasing

- Inventory

- Cost calculation

- Cost reporting

- General accounting

- Cash flow

- Tax calculation

- Tax payments

It process is carried out by a synergistic combination of computer and human resources. The MRP II differs fundamentally from point contact planning, in which individual characteristics and functions have their own dedicated systems.

The system integrates these modules together so that they use common data and freely exchange information, in a model of how a manufacturing enterprise should and can operate. It approach is therefore very different from the “point solution” approach, where individual systems are deployed to help a company plan, control or manage a specific activity. It is by definition fully integrated or at least fully interfaced.

- This systems can provide:

- Better control of inventories

- Improved scheduling

- Productive relationships with suppliers

MRP II systems have been implemented in most manufacturing industries. Some industries need specialised functions e.g. lot traceability in regulated manufacturing such as pharmaceuticals or food. Other industries can afford to disregard facilities required by others e.g. the tableware industry has few starting materials – mainly clay– and does not need complex materials planning. Capacity planning is the key to success in this as in many industries, and it is in those that MRP II is less appropriate.

This is not exclusively a software function, but a marriage of people skills, dedication to data base accuracy, and computer resources. It is a total company management concept for using human resources more productively.