Target costing is an approach to determine a product’s life-cycle cost which should be sufficient to develop specified functionality and quality, while ensuring its desired profit. It involves setting a target cost by subtracting a desired profit margin from a competitive market price. A target cost is the maximum amount of cost that can be incurred on a product, however, the firm can still earn the required profit margin from that product at a particular selling price. Target costing decomposes the target cost from product level to component level. Through this decomposition, target costing spread the competitive pressure faced by the company to product’s designers and suppliers. Target costing consists of cost planning in the design phase of production as well as cost control throughout the resulting product life cycle. The cardinal rule of target costing is to never exceed the target cost. However, the focus of target costing is not to minimize costs, but to achieve a desired level of cost reduction determined by target costing process.

Process of target costing

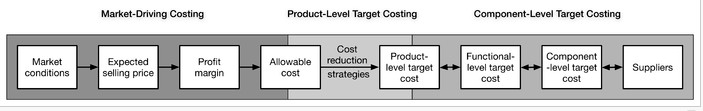

The process of target costing can be divided into three sections: the first section involves in market-driven target costing, which focuses on studying market condition to identifying product’s allowable cost in order to meet company’s long-term profit at expected selling price; the second section involves in performing cost reduction strategies with the product designer’s effort and creativity to identify the product-level target cost; the third section is component-level target cost which decomposes the production cost to functional and component levels to transmit cost responsibility to suppliers.

Market-driven target costing

Market driven target costing is the first section in target costing process which focuses on studying market condition and determining company’s profit margin in order to identify allowable cost of a product. Market driven costing can go through 5 steps including: establish company’s long-term sales and profit objective; develop the mix of products; identify target selling price for each product; identify profit margin for each product; and calculate allowable cost of each product.

Company’s long-term sales and profit objective are developed from extensive analysis of relevant information relating to customers, market and products. Only realistic plan is accepted to process the next step. Product mix is designed carefully to ensure that it satisfies many customers, but also does not contain too many products to confuse customers. Company may use simulation to explore the impact of overall profit objective to different product mixes and determine the most feasible product mix. Target selling price, target profit margin and allowable cost are identified for each product. Target selling price need to consider to the expected market condition at the time launching the product. Internal factors such as product’s functionality and profit objective, and external factors such as company’s image or expected price of competitive products will influence target selling price. Company’s long-term profit plan and life-cycle cost are considered when determining target profit margin. Firms might set up target profit margin based on either actual profit margin of previous products or target profit margin of product line. Simulation for overall group profitability can help to make sure achieving group target. Subtracting target profit margin from target selling price results in allowable cost for each product. Allowable cost is the cost that can spend on the product to ensure meeting profit target if selling it at target price. It is the signal about the magnitude of cost saving that team need to achieve.

Product-level target costing

Following the completion of market-driven costing, the next task of the target costing process is product-level target costing. Product-level target costing concentrates on designing products that satisfy the company’s customers at the allowable cost.

The first step is to set a product-level target cost. Since the allowable cost is simply obtained from external conditions without considering the design capabilities of the company as well as the realistic cost for manufacturing, it may not be always achievable in practice. Thus, it is necessary to adjust the unachievable allowable cost to an achievable target cost that the cost increase should be reduced with great effort. The second step is to discipline this target cost process, including monitoring the relationship between the target cost and the estimated product cost at any point during the design process, applying the cardinal rule so that the total target costs at the component-level does not exceed the target cost of the product, and allowing exceptions for products violating the cardinal rule. For a product exception to the cardinal rule, two analyses are often performed after the launch of the product. One involves reviewing the design process to find out why the target cost was unachieved. The other is an immediate effort to reduce the excessive cost to ensure that the period of violation is as short as possible. Once the target cost-reduction objective is identified, the product-level target costing comes to the final step, finding ways to achieve it. Engineering methods such as value engineering (VE), design for manufacture and assembly (DFMA), and quality function deployment (QFD) are commonly adopted in this step.

Stay Ahead with the Power of Upskilling - Invest in Yourself!

Stay Ahead with the Power of Upskilling - Invest in Yourself!