Freight management involves logistics planning, which includes a generalized approach to corporate strategic planning is outlined, and this is linked to a specific logistics design strategy. It involves product characteristics, the product life cycle, packaging and unit loads.

The process of exchanging something of value between two parties (e.g., producers and suppliers, producers and consumers, producers and distributors, or distributors and consumers) that are distant from each other often triggers transportation activities. Although this process can take place anywhere in between the respective locations of those two parties, its location can either boost or undermine transportation activities.

However, if that remote location of the marketplace can offer a diverse range of product assortments due to its scale (size), it may still draw consumers from longer distances. In other words, the location and size of the trading area can dictate transportation activities. This concept can be explained by the Central Place Theory. It helps explain reasons why people gather together in cities and towns to exchange their goods, services, and ideas.

The use of a unit load enables goods and packages to be grouped together and then handled and moved more effectively using mechanical equipment. Two familiar examples are the wooden pallet and the large shipping container, both of which, in their different ways, have revolutionized physical distribution and logistics. From the product point of view, it is possible to introduce unit load systems to alter the characteristics of a product and thus make more effective e logistics possible.

Concept of Unit Load

Principle of Unit Load states that, “it is quicker and economical to move a lot of items at a time rather to move each one of them individually”. In other words, this principle suggested that, the larger the load handled, the lower the cost per unit handled.

For small parts, or parts where machines are engaged for handling, movements are made in containers. When machines are used for materials handling, units can be made machine size rather man size. Unit load principle implies that materials should be handled in most efficient, maximum size unit, mechanical means to reduce the number of moves needed for a given amount of material.

A number of items, or bulk material, so arranged or restrained that the mass can be picked up and moved as a single object too large for manual handing, and which upon being released will retain its initial arrangement for subsequent movement.

Characteristics of a Unit Load

- There should be minimum number of handlings.

- Manual handling should be eliminated.

- Materials are assembled into a unit load for economy of handling and storage.

- Redesign packages, containers etc. for better assembly into unit loads and retain them to prevent product damage.

- Unit load should be as large as possible within the constraints of building, equipment etc.

Types of Unit Loads

These are the key to most unit load applications, and are made of wood, plywood, steel, light weight metals, plastic etc. These are constructed either a rigid one or collapsible to permit their return by common carrier in a minimum space.

Unit Load on a Platform

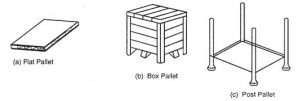

- Pallet: Pallet is a horizontal portable platform device used as a base for handling materials in a unit load. Pallet is basically a portable platform, with or without superstructure, and consists of two decks separated by bearers or a single deck supported by small feet and handled by means of fork lift trucks and pallet trucks. The pallets may be flat pallets, box pallets and post pallets, as shown below

- Skid: These are non-stackable, single-faced device elevated above the floor to allow lifting by lift trucks. Goods may be loaded on the skids and then picked up with lift trucks. The skid can be loaded as a unit and transferred from position to position without subsequent loading and unloading like pallets as shown

Unit Load on a Sheet

- Flat Sheets: The sheet may be plain or corrugated, and made of cardboard, chip board or plywood.

- Molded Sheets: These are especially formed to facilitate building the load. These sheets are made in such way that they have hollow spaces for fork entry.

Unit Load on a Rack or Trays

These racks or trays are designed to hold parts in a desired position and may have wheels. These are provided with inserts, holes or pegs or dividers for ease of handling and inspection etc.

Unit Load in a Container

Containers are made in the form of full or partial enclosures to suit requirements. Containers include boxes, bins, crates etc.

Self-contained Unit Load

These do not require auxiliary aids. Examples of such unit loads are bundles, bales, interlocked unit loads and fastened unit loads.

Securing the Unit Load

Commonly used methods of securing the unit loads (unitizing) are:

- Steel trap.

- Cloth or paper tape.

- Chip board or paper sheet.

Designing the Unit Load System

Factors considered for designing:

For designing (planning) the unit load system following factors should be considered:

- Material and its characteristics.

- Quantity to be handled and duration.

- Starting point and destination.

- Loading and unloading techniques.

- Objective of space utilisation.

- Environment, storage requirements in route.

- Limitations of aisles, doors, height, column, machine arrangement, and storage space dimensions, etc.

- Weight limitations.

- Volume limitations.

- Cost of handling equipment and other handling aids.

- Cost of consumable (expendable) unitizing materials.

- Labour cost.

- Time consumed in preparing the unit load.

- Cost of entire handling system.

Criteria for unit load design:

- Mechanical strength.

- Low cost.

- Optimum size.

- Universal in application.

- Easy to store.

- Ease of unitising or de-unitising.

- Low maintenance

After having understood the factors and criteria for unit load design, next step is to design (or plan) the unit loads. A logical approach must be followed to solve the unit load problem.

Guidelines for Unit Load

- Whether unit load concept is necessary: First of all it is necessary to determine whether there is need for unitizing at all? For this purpose size, volume, frequency of movement, distance, equipment used, cost justification, and customers’ acceptance are the main considerations.

- Selection of type of unit load: Type of unit load is selected by considering the materials whether it can withstand load, and whether its irregular shape is strong enough to support the load.

- Establish distribution requirement: Objective of designing a unit load is more efficient shipping and subsequent handling, storage and disbursement.

- Determining the size of unit load: Size and shape of the unit load is decided considering the size and shape of the product, size of the shipping container.

- Configuration of the unit load: This includes the shape and pattern of the loading, shape and dimensions of the items to be unitized and whether the items are unstackable, whether auxiliary attachments like sides, ends or corners, or some kinds of container can be provided to unitize the load.

- Method of building the unit load: Method of building the load is decided considering different factors along with some additional factors, like, unitising aids, methods of building unit load i.e. manual, semi-mechanised or palletizers, and method of securing the unit load e.g. steel strap, wire, rope, tape of cloth or paper, adhesives, chip board or paper sheets, rubber bands, filament tapes, storage aids, interlocking etc.

Shippers often work under the assumption that the way they ship freight (and the associated costs) are pretty much fixed and can’t change. A smart approach opens the door to savings that can reach as high as 50% of “business as usual” freight charges. Few suggestions are listed

- Contract steady lane volume. If your carrier knows he is going to work with you every day, and is going to get a regular flow of freight in the same lane, he can market those backhauls and build out his network. As a result, you’ll pay less because the carrier is more efficient. Furthermore, when capacity tightens, these carriers will focus on moving the freight of the people who are loyal and have reliable freight volumes.

- Ship on off-peak days. Shipping a day later or earlier can yield measurable savings. Friday is typically an off-peak day for shipping consumer goods because most customers try to get their product to store by Thursday, so it can be shelved Friday and ready for sale at the weekend. Mondays also tend to be low-volume days when carriers are typically looking for freight. Obviously, it depends on the cargo – canned goods, e.g. have more of a window than fresh goods. Shipping off-peak is certainly a great option for shippers of non-consumer type products.

- Find a consolidation program near you to handle smaller shipments. Freight consolidation is a no-brainer – you combine your LTL (Less than truckload) shipments with other nearby companies shipping to the same mass retailers and grocery chains for direct delivery, and everyone wins. Suppliers like you pay only for your share of a less-expensive TL shipment. And retailers receive loads on time and get the same volume of goods in fewer, fuller loads to keep their dock bays open and cut labor costs. Where can you find suitable shipper-partners? Local Chambers of Commerce or other business organizations are one place. You can also work with a 3PL with a retail consolidation program that serves multiple companies shipping to the same retail customers.

- Develop relationships. When shippers develop more strategic, longer-term carrier relationships, they create transportation management advantages that have bottom line implications. Longer term contracts give the carrier time to mine for other customers in the area to create a more efficient network with minimal deadhead miles. A carrier that is maximizing assets is more profitable and can afford to give you better rates. A longer term deal, say 3 years, also locks in that rate for the contract period, instead of changing – and maybe going up – every year. Oh, and you get better service, too, from a carrier you’ve committed to long-term. Hard to put a price on that, but it’s significant.

- Increase delivery lead times. Any time you can introduce planning into the supply chain, and maximize the advance notice to the carrier about future loads, they are able to maximize assets, including trucks, drivers and warehousing space. An advance shipping notice allows a carrier to line up the assets and resources, plain and simple. One of the biggest costs for carriers is paying for a trailer to sit idle at someone’s facility, waiting to load up. Having better planning allows carriers to reduce those costs, and then pass some of them on to you. Planning can be improved on all aspects of the supply chain – pick up, staging, live-loading. The longer the notice, the more carriers can do behind the scenes to be more efficient and come to you with a better price.

- Reduce Dunnage. A lot of products require air bags, strapping, blocking and bracing to prevent them knocking together during a trip across the ocean or on a long-distance truck ride. But sometimes shippers go overboard in trying to protect a product. Carriers can help you skinny down on that dunnage and reduce shipping costs – without increasing damage. Don’t be afraid to seek their advice.

- Develop a reputation for loading quickly. When carriers develop pricing, they typically assume a 2-hour load window. But if the carrier knows they’re picking up at a place where cargo will get loaded in an hour that affects the price. It also inclines the carrier to work with that shipper. Shippers with consistent load time performance can even get these favorable load times baked into the rate. This avoids the need to chase down assessorial charges – a huge time drain. A shipper that operates efficiently saves money and has carriers lining up to serve them – a two-fold benefit!

- Offer night pick-ups. This may give carriers an opportunity to make your load into a backhaul by offering them pick-up times after most other shippers have closed the dock – 6-12 p.m. E.g. a carrier might turn down a load that’s requested for a mid-afternoon pick-up because it conflicts with another run. But a later pick-up allows him to make the delivery and fill his backhaul with your freight. This is yet another way of helping the carrier maximize utilization of assets, especially on longer hauls.

- Minimize the number of pallet spaces needed when shipping LTL. Maximizing the cube of a product, stacking the product so you take fewer pallet spots, even boxing it differently, all help make it easier to get more cargo packed onto a pallet and into a trailer. For instance, if you put a small component in a large box, you can’t get that many on a pallet, but if you have them in small boxes, you can load the pallet out and save pallet spaces. Ask your carrier for a recommendation on building more efficient pallets. The recommendation will depend on the type of product being shipped.

- Ship more products, less often. Encourage customers to take larger orders. It’s a lot cheaper to ship six pallets at once than to send two pallets every two days. But retailers tend to look for smaller shipments more often, so you need to create incentives to take more inventory than they think they need. One way is to agree to share freight savings with the retailer. Another is to consider Vendor Managed Inventory, where the retailer is not charged for the item until it’s on the shelf.

- Use a load board. If you have a one-off shipment and you throw it on a load board, then you’ll probably catch a low rate, especially if the carrier can handle it as a backhaul. Many smaller shippers, who are in the manufacturing business and not in the freight business, don’t have freight logistics people on staff, so they are unfamiliar with load boards. Carriers love backhauls because they’re making money when they would otherwise incur costs for empty miles. For a backhaul, many are willing to offer a rate that simply covers fuel costs, plus a little bit extra.

- Look for carriers based near your ship-to points. That way your load is more likely to become a backhaul for them and you’ll get a lower rate. Filling empty miles is the way carriers make better money, and a great way for you to reduce freight costs. It’s surprising how many shippers don’t investigate carrier terminals near their frequent ship-to locations.

- Get logistics involved earlier in decisions about product design, packaging, and carton selection. These are all things that impact the ability to max out the cube of your trailers. What many companies don’t realize is that packaging is the smallest cost segment in the supply chain, comprising less than 10% of each supply chain dollar. In contrast, warehousing is about 25% of the cost and transportation 60% of the cost. So it makes sense to design packaging and to spec carton sizes with freight efficiency in mind. The marketers currently making these decisions won’t have this mindset. Most companies just don’t think about getting logistics people involved in packaging decisions.

- Outsource your transportation department. For smaller companies especially, freight management is not a core competency. Hiring, training and maintaining a transportation staff, and keeping up with systems requirements, can be expensive and time-consuming. Outsourcing freight management transfers the financial burden of staffing and capital expenditures and also opens the door to innovative solutions that on-the-ball carriers should be suggesting. Also, carriers will simply operate more efficiently than you because they can buy things, like fuel, in bulk. If you own your own trucks, consider parking them and investigate outsourcing freight to outside experts.

Stay Ahead with the Power of Upskilling - Invest in Yourself!

Stay Ahead with the Power of Upskilling - Invest in Yourself!