TQM Frameworks

In the early 1980s when organizations in the West started to be seriously interested in quality and its management, many attempts to construct lists and TQM frameworks to help this process.

In the West the famous American ‘gurus’ of quality management like W. Edwards Deming, Joseph M. Juran and Philip B. Crosby, started to try to make sense of the labyrinth of issues involved. Morever, it included the tremendous competitive performance of Japan’s manufacturing industry.

Above all, Deming and Juran had contributed to building Japan’s success in the 1950s and 1960s. However, it was appropriate that they should set down their ideas for how organizations could achieve success.

Juran’s ten steps to quality improvement

- Firtly, building awareness of the need and opportunity for improvement.

- Then, set goals for improvement.

- After that, organizing to reach the goals (establish a quality council, identify problems, select projects, appoint teams, designate facilitators).

- Then, providing training.

- Morever, carrying out projects to solve problems.

- Then, reporting progress.

- Giving recognition.

- Communicating with results.

- Keeping score.

- Lastly, maintaining momentum by making annual improvement part of the regular systems and processes of the company.

Four absolutes of Phil Corsby as a Quality Director of ITT

- Firstly, definition – conformance to requirements.

- Then, system – prevention.

- After that, performance standard – zero defects.

- Lastly, measurement – price of non-conformance.

He also offered management 14 steps to improvement:

- Make it clear that management is committed to quality.

- Form quality improvement teams with representatives from each department.

- Determine where current and potential quality problems lie.

- Evaluate the cost of quality and explain its use as a management tool.

- Raise the quality awareness and personal concern of all employees.

- Take actions to correct problems identified through previous steps.

- Establish a committee for the zero defects program.

- Train supervisors to actively carry out their part of the quality improvement program.

- Hold a ‘zero defects day’ to let all employees realize that there has been a change.

- Encourage individuals to establish improvement goals for themselves and their groups.

- Encourage employees to communicate to management the obstacles they face in attaining their improvement goals.

- Recognize and appreciate those who participate.

- Establish quality councils to communicate on a regular basis.

- Do it all over again to emphasize that the quality improvement program never ends.

Basics TQM Framework

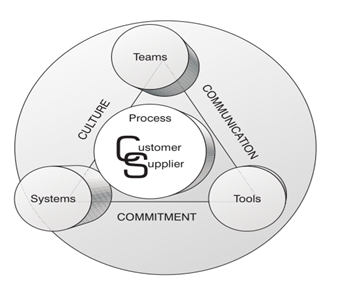

TQM approaches to the direction, policies and strategies of the business or organization. Moreover, these ideas were captured in a basic framework . Above all, the TQM model was in demand in the UK through the activities of the Department of Trade and Industry (DTI) programs. And, the customer/supplier or ‘quality chains’ and the processes that were within them was the core of this TQM model.

Above all, this simple framework was useful and it was helpful for groups of senior managers throughout the world get started with TQM. Moreover, the key was to integrate the TQM activities, based on the framework, into the business or organization strategy

Learn and enhance your knowledge in TQM frameworks skills. Become a Certified TQM Professional Now!