Plumbing is a general term indicating the Practice, materials and fixtures used in installation or maintenance of all piping, fixtures, appliances and other appurtenances used in connection with water supply system as well as sanitary and storm water drainage system within a building and its connection to the point of public disposal. Plumbing is the system of pipes, drains fittings, valves, valve assemblies, and devices installed in a building for the distribution of water for drinking, heating and washing, and the removal of waterborne wastes, and the skilled trade of working with pipes, tubing and plumbing fixtures in such systems. Thus, plumbing usually deals with laying of pipe lines which provide a means of transportation for fluids.

Plumbing system comprises of

- Plumbing water supply system

- Plumbing drainage system

Types of distribution systems

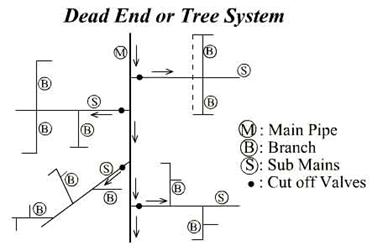

Tree/ Dead End System – In this system a single mains pipe is used and sub mains pipes branch out from this mains pipe. These sub mains are further divided into branches that supply water to various households.

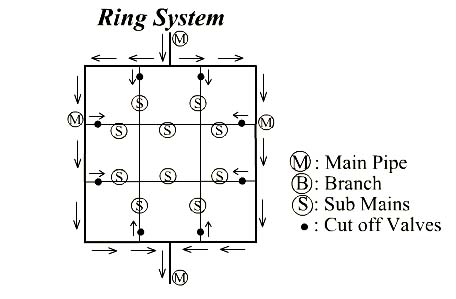

Ring System – This system is utilised in more developed cities which are planned and designed in a consistent way. Here the mains pipe circles or forms a boundary across the distribution area and subsequent sub mains emerge from the mains pipe.

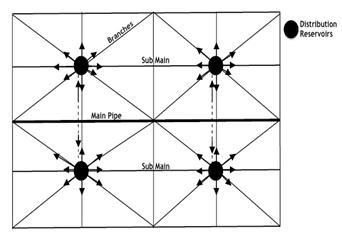

Radial system – This system is usually employed in the European cities. It is the most efficient method of water supply system. Here water is stored in distribution reservoirs that are placed at junctions (usually beneath road junctions), sub mains pipes then emerge radially from these distribution reservoirs to distribute water to the homes.

Piping and plumbing fittings

A fitting is used in pipe plumbing systems to connect straight pipe or tubing sections, to adapt to different sizes or shapes, and for other purposes, such as regulating or measuring fluid flow. The term plumbing is generally used to describe conveyance of water, gas, or liquid waste in ordinary domestic or commercial environments, whereas piping is often used to describe high-performance (e.g. high pressure, high flow, high temperature, hazardous materials) conveyance of fluids in specialized applications. The term tubing is sometimes used for lighter-weight piping, especially types that are flexible enough to be supplied in coiled form.

Elbow – An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 90° or 45° angle, though 22.5° elbows are also made. The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow. A 90 degree elbow is also called a “90 bend” or “90 ell”. It is a fitting which is bent in such a way to produce 90 degree change in the direction of flow in the pipe. It is used to change the direction in piping and is also sometimes called a “quarter bend”. A 90 degree elbow attaches readily to plastic, copper, cast iron, steel and lead. It can also attach to rubber with stainless steel clamps. It is available in many materials like silicone, rubber compounds, galvanized steel, etc. The main application of an elbow (90 degree) is to connect hoses to valves, water pressure pumps, and deck drains. These elbows can be made from tough nylon material or NPT thread. A 45 degree elbow is also called a “45 bend” or “45 ell”. It is commonly used in water supply facilities, food industrial pipeline networks, chemical industrial pipeline networks, electronic industrial pipeline networks, air conditioning facility pipeline, agriculture and garden production transporting system, pipeline network for solar energy facility, etc. Most elbows are available in short radius or long radius variants. The short radius elbows have a center-to-end distance equal to the Nominal Pipe Size (NPS) in inches, while the long radius is 1.5 times the NPS in inches. Short elbows are widely available, and are typically used in pressurized systems.

Long elbows are typically used in low-pressure gravity-fed systems and other applications where low turbulence and minimum deposition of entrained solids are of concern. They are readily available in acrylonitrile butadiene styrene (ABS plastic), polyvinyl chloride (PVC) for DWV, sewage and central vacuums, chlorinated polyvinyl chloride (CPVC) and copper for 1950s to 1960s houses with copper drains.

Coupling – A coupling connects two pipes to each other. If the size of the pipe is not the same, the fitting may be called a reducing coupling or reducer, or an adapter. By convention, the term “expander” is not generally used for a coupler that increases pipe size; instead the term “reducer” is used.

Tee – A tee is the most common pipe fitting. It is available with all female thread sockets, all solvent weld sockets, or with opposed solvent weld sockets and a side outlet with female threads. It is used to either combine or split a fluid flow. It is a type of pipe fitting which is T-shaped having two outlets, at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. A tee is used for connecting pipes of different diameters or for changing the direction of pipe runs. They are made of various materials and available in various sizes and finishes. They are extensively used in pipeline networks to transport two-phase fluid mixtures. They are categorized as

- Equal

- Unequal

When the size of the branch is same as header pipes, equal tee is used and when the branch size is less than that of header size, reduced tee will be used. Most common are tees with the same inlet and outlet sizes. Some of the industrial tees are Straight Tee, Reducing Tee, Double Branch Tee, Double Branch Reducing Tee, Conical Tee, Double Branch Conical Tee, Bullhead Tee, Conical Reducing Tee, Double Branch Conical Reducing Tee, Tangential Tee, and Double Branch Tangential Tee.

Cross – Cross fittings are also called 4-way fittings. If a branch line passes completely through a tee, the fitting becomes a cross. A cross has one inlet and three outlets, or vice versa. They often have solvent welded socket ends or female threaded ends.

Cross fittings can generate a huge amount of stress on pipe as temperature changes, because they are at the center of four connection points. A tee is more steady than a cross, as a tee behaves like a three-legged stool, while a cross behaves like a four-legged stool. (Geometrically, “any 3 non-collinear points define a plane” thus 3 legs are inherently stable.) Crosses are common in fire sprinkler systems, but not in plumbing, due to their extra cost as compared to using two tees.

Unions – A union is similar to a coupling, except it is designed to allow quick and convenient disconnection of pipes for maintenance or fixture replacement. While a coupling would require either solvent welding, soldering or being able to rotate with all the pipes adjacent as with a threaded coupling, a union provides a simple transition, allowing easy connection or disconnection at any future time. A standard union pipe is made in three parts consisting of a nut, a female end, and a male end. When the female and male ends are joined, the nuts then provide the necessary pressure to seal the joint. Since the mating ends of the union are interchangeable, changing of a valve or other device can be achieved with a minimum loss of time.

Valves – Valves are equipment designed to stop or regulate flow of any fluid (liquid, gas, condensate, stem, slurry, etc.) in its path. Valves are categorized depending on their applications like isolation, throttling, and non-return. Various type of valves are available depending upon the type of construction as follows

- Gate valve – used for isolation only

- Plug valve – used for isolation only

- Globe valve – used for throttling

- Butterfly valve – used for isolation as well as throttling

- Check valve – used for preventing reverse flow (non-return)

- Diaphragm valve – used for isolation as well as throttling

- Ball valve – used for isolation only

Learn, Certify, Succeed: A Smarter Way to become Job-Ready Now !

Learn, Certify, Succeed: A Smarter Way to become Job-Ready Now !