System availability is determined by reliability (the probability of the system not failing) and maintainability (the ability to restore the system to service). The various availabilities depend on the downtimes that are included in the total time with the failure rate of the system is assumed to be constant.

Achieved availability – It is very similar to inherent availability with the exception that PM downtimes are also included. Specifically, it is the steady state availability in an ideal support environment (i.e. readily available tools, spares, personnel, etc.) The achieved availability is sometimes referred to as the availability seen by the maintenance department (does not include logistic delays, supply delays or administrative delays).

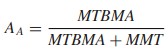

Achieved availability can be computed by looking at the mean time between maintenance actions MTBMA (both preventive and corrective) and the mean maintenance time, MMT

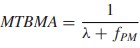

Assuming constant failure rate MTBMA can be calculated as:

where: λ = the failure rate (assuming all failures are repaired).

fPM = the frequency of preventive maintenance, the reciprocal of PM Cycle.

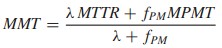

The mean maintenance time MMT can be further decomposed into the effects of preventive and corrective maintenance as:

where MTTR is the mean CM time and MPMT is the mean PM time.

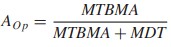

Operational Availability – It is a measure of the ‘real’ average availability over a period of time in an actual operational environment. It includes all experienced sources of downtime, such as administrative downtime, logistic downtime, and so on

where: MDT= Mean maintenance downtime.

MDT= MMT+ (logistics delay time) + (administrative delay time).