Order processing: The distribution process is activated by a customer order. The order cycle includes the time spent in processing the order as well as the time taken by the physical motion and therefore depends on the speed and efficiency of (hest.: operations, Electronic systems are now available to reduce the time needed for the flow of information and communications.

- Order processing is the receipt and transmission of sales order information.

- Efficient order processing facilitates product flow.

- There are three main tasks in order processing.

- Order entry begins when customers or salespersons place orders by mail, telephone, or computer.

- Order handling involves several tasks.

- Transmission of orders to the warehouse

- Verification of product availability

- Checking of prices, terms, and customers’ credit ratings

- Instructions to the warehouse to fill the order

- Order delivery

- The warehouse schedules pickup with an appropriate carrier

- Premium transportation is used if the customer is willing to pay for rush service.

- The customer is billed; inventory records are adjusted; and the order is delivered.

- Methods of order processing

- Manual order processing suffices for a small volume of orders and is more flexible in special situations.

- Electronic data interchange (EDI) integrates order processing with production, inventory, accounting, and transportation.

- EDI is an information system for the supply chain.

- Many companies are pushing their suppliers toward EDI to reduce distribution costs and cycle times.

- The Internet is another opportunity for EDI systems.

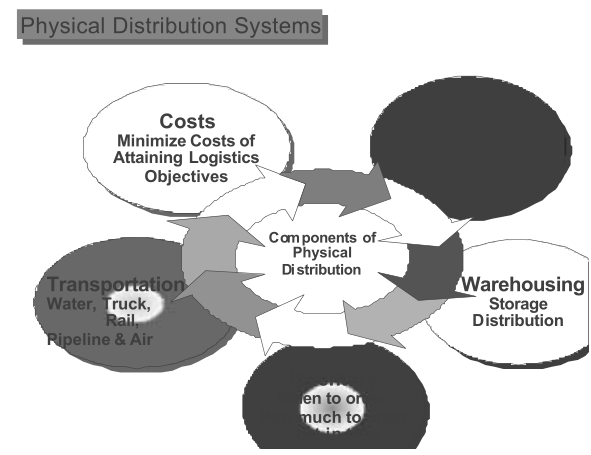

Since the costs of physical distribution can amount to more than a quarter of sales price at manufacturing level and the necessary assets can amount to as much as a third of the corporate assets, it is important for management to keep these costs down. It is possible to keep visible costs, such as ware- housing, inventory and transport, down when the logistics functions are integrated. The invisible costs are due to customer dissatisfaction caused by late deliveries, lost sales/orders, etc. Control of these costs, both visible and hidden, is very difficult owing to the effect of any changes on customer service levels. Improvement of the latter can increase costs and a decrease in costs may mean a drop in the quality of the service. Physical distribution management provides guidelines for keeping a balance between cost and service levels

Transport

Transport is an important part of logistics since inadequate transport provision can increase inventory costs prohibitively, as well as the investment in inventory; it can also cause customer dissatisfaction and increase the invisible costs dramatically. Therefore the selection of the right mode of transport, which is efficient and dependable, is essential for the achievement of distribution objectives. The five modes are: rail, road, sea/ waterways, air and pipeline, plus combinations of some or all of these. The possibilities must be considered for cost, reliability and possibility of risk/damage.

Warehousing

This can be either company-owned or leased/rented from others. The advantages of company-owned warehousing are: greater flexibility and control, better information feedback and potentially lower unit costs. Regional distribution centres serving regional markets are a new development in the Europe of today; if they are highly automated and can cater for packaging of orders, maintenance of full inventory and combining products from different production centres, they can go a long way towards achieving improved efficiency and increased customer satisfaction. For example, some companies are considering locating regional distributor centres in Maastricht in the Netherlands, Calmar in Alsace and in Bavaria. These regions are also developing the type of infrastructure needed for the functioning of such centres.

The advantages of leasing are: location and space flexibility, and possibly lower costs for seasonal businesses. There is also wider choice available for the type of warehousing needed, e.g. special commodity warehouses for storing agricultural products or refrigerated warehouses. Warehousing firms may also offer a variety of extra services to compete with each other.

It is possible to reduce the need for warehousing by choosing a slower form of transport, e.g. storage in transit. The number and location of warehouses is decided by their purpose and the level of customer service to be provided. They should be so positioned that they will yield the desired service level after all the variables are considered. This solution is unique to each business. The transportation costs decrease as the number of warehouses increases; while the inventory and warehousing costs increase at a diminishing rate.

The locations of the warehouses affect the customer service level and the total costs; they also have a significant effect on the competitive powers of the business. A number of models have been developed to help management make better decisions. The significant factors are the estimates of lost sales due to the distance of the warehouses from the customers, and the costs of operation and of transport.

Inventories may be held in the material management cycle to supply the production function or in the distribution function to meet customer demand. Inventory control in the latter is crucial to efficient physical distribution. Inventory represents the largest single investment for manufacturers of packaged consumer goods, amounting up to a third of their asset investment. High inventory levels are necessary in competitive conditions where the market segments are diverse in nature and customers are used to obtaining goods quickly.

The objective of inventory control is to minimize total inventory costs subject to demand and service level constraints. The main costs are due to holding inventory, ordering and the risks of stock outs. The system has to figure out how much to re order, when to re-order and how to control stock outs at the minimum cost.

There are a number of inventory control systems available, depending on the type of business. Distribution requirements planning (DRP) systems deal with connecting the production process with the other inventory levels further down the channel. They operate on the assumption that they are managing inventories intended to resupply other inventories.

An accurate forecast of future demand is obviously essential for any inventory control system, Lack of such a forecast or inaccuracies can wreck havoc throughout the physical distribution channels. Unpredicted increases also cause stock outs and loss of orders in the future, Every firm and every channel member has to balance the costs of holding higher inventory levels against the costs of stock outs.