S&OP is the most critical and fundamental process for any organization who is into manufacturing of products.

This process aligns both sales & operations team on a common plan, basically this process is a tool to identify constraints and resources required to execute a sales plan so as to maximize organization revenue and profit

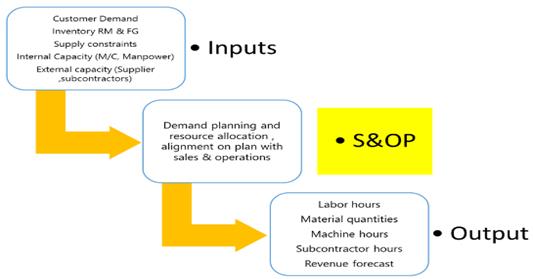

Input to S&OP process is demand plan, inventory, capacity requirements and supply constraints. The owners of the process than churns out and identify requirements for material procurement, capacity investment, man hours, estimated revenue, subcontracted capacity requirement etc.

An efficient and collaborative S&OP process is one of the most important pillar of planning process and its of paramount importance of successful operation of any manufacturing organization

Frequency of S&OP process depends on scale and complexity of operations. It can be weekly, biweekly or monthly.

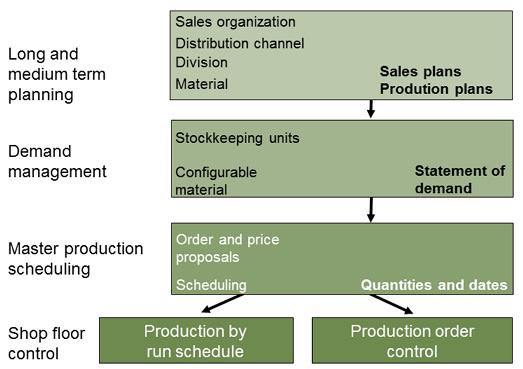

Sales and Operations Planning (SOP) covers various activities including the specification of medium term and long term sales volumes and the approximate planning of the production activities that are required to meet these volumes. The enormous amount of data involved means that this is not a highly detailed form of planning with exploded bills of materials and scheduling via routing, but rather a rough estimate of the feasibility of the proposed plans.

The principle of SOP

SOP can be done at the level of finished products or using product groups. Any combinations of materials or even of product groups themselves can be grouped together into other product groups.

The exact breakdown is done at the level of the material and the plant.

Benefits

Companies that use S&OP can give a number of benefits such as a greater visibility of the demand and supply across the enterprise, improved inventory management, increased promotional planning, increased accuracy in budget forecasting, and an improved product lifecycle management process.

Tactical Planning

Whereas strategic planning looks at the company’s plan years into the future, tactical plans look at the company’s business plan over the coming year. Tactical plans take into account overall strategies of the company, which are found in the strategic plan. Sales and operations planning are aimed at helping to provide companies develop and align the tactical plans developed by the various business areas. There are two approaches that are used in sales and operations planning; top-down planning and bottom-up planning.

Top-Down Planning

Top-down planning is the simplest approach to sales and operations planning.

In this approach, there is a single sales forecast that drives the planning process. The forecast is derived from a combination of products and services that require similar resources, for example, a number of manufactured finished products. Using top-down planning, the management can create tactical plans based on the overall forecast and divide the resources across the finished foods in the plan.

Bottom-Up Planning

This approach is used by companies that do not have a stable manufacturing schedule and the number and type of finished goods can change from month to month. In this scenario, the sales forecast is not helpful for resource planning. The management needs to calculate the resources for each of the products and then amalgamate the resources to get an overall picture of resource requirements.

Production Plans

After a company has worked through their sales forecasts and calculated the resource requirements, the various alternate production plans should be generated. There are three approaches that are used for the production plan: level, chased, and mixed.

The level production plan is used where the cost of making a change in the production level is extremely expensive, while the cost of holding inventory is very low, for example in the oil industry. Using the level production plan, the production remains constant and inventory is used to absorb the differences between the sales forecast and the production.

The chase production plan is the opposite of the level production plan. In this production plan, the production is changed for each time interval of the plan to match the sales forecast for that interval.

With this approach the production is always chasing the demand, hence the name chase production plan. This approach is best used for companies who either cannot hold inventory. Otherwise, to do so is extremely expensive, while changes in production cost very little.

The mixed production plan takes elements from both the chase and level plans, where there will be variances in production and inventory levels which will produce the best production plan.

S&OP is the result of monthly planning activities. It is usually based on an Annual Operations Plan (AOP) that acts as the company’s annual target in terms of sales and supply. Therefore, the sales and operations plans are a means to gradually accomplish the AOP targets – by linking monthly sales and marketing planning directly to the operations side of a business.

The planning horizon for a typical S&OP process is long term and extends over 18–36 months. The selection of a time horizon is an important decision and there are different factors that influence this decision including type of industry, product characteristics, and the time of the year when S&OP planning takes place. Additionally, the S&OP process is conducted at an aggregate level. The focus is on commonly on product families and not every single product.

S&OP best practices share a common set of approaches:

- Rely on a phased approach: S&OP is much more an integrated set of business processes and technologies than a single, all-encompassing process or technology. If you just focus on the implementation of a new technology and think that S&OP will miraculously take shape, you’re wrong.

- Develop an “outside-in” sequence of S&OP initiatives: typically, the events that will have the most profound and negative impact on your sales and operations planning are those outside of your control. For the most part, these are due to the decisions and actions of your customers, partners, and competitors, which have a direct impact on your revenue and your competitor’s strategy.

- Focus on more information, less data: another key to successful S&OP is clean, current, and accurate data. Plans are often slowed down by the effort of gathering data that has minimal importance to the overall project. It is important to ensure that you know exactly what business problem you are trying to resolve and understand the minimum data necessary for the project.

- Provide effective leadership for the process. S&OP crosses organizational boundaries – that is its strength but also its vulnerability. Many businesses find that their attempts to implement S&OP are frustrated by internal tensions between departments. Classic best practice suggests that S&OP must be owned to the Chief Executive Officer. If that is not possible then a strong united coalition of department heads may be able to lead the process if they set clear ground rules and boundaries for working together.