The channel performance is evaluated on the basis of the following criteria.

Financial evaluation

Under financial evaluation the channel members accepts low level of channel performance in the short run. In the long run there must be positive financial returns to sustain channel relationship.

Working relationship

Following factors must be considered when evaluating channel performance

- Channel power such as reward power, legitimate power, export power, referent power, coercive power, channel leader power.

- Channel conflict

- Channel cooperation

Legal and ethical issues

- Ensure no laws are violated

- Whether any exclusive territory is set-up

- Whether any exclusive dealing arrangements are made

- Whether resellers are bound to typing contracts

Level of market exposure

Intensive Exposure: It involves selling through all responsible and suitable wholesalers and retailers who will stock and/or sell the product.

Selective Exposure: It involves selling through only those middlemen who will give the product special attention. In case of selective distribution avoid dealing with middlemen who have poor credit standing or make too many returns or require service often or places small order. Note this is a less expensive method of distribution than intensive distribution.

Exclusive Exposure: It involves selling through only one middleman in a particular geographic region.

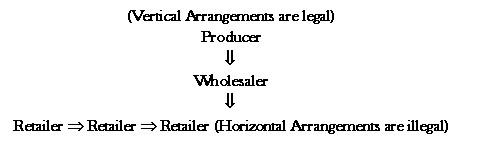

Figure: Cooperative arrangement in exclusive distribution

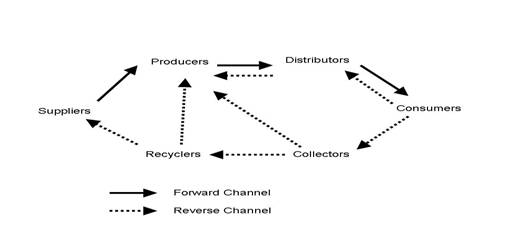

Forward and Reverse Channels of Distribution

The conventional forward channel in freight distribution is well understood with raw materials, parts and finished goods flowing from suppliers to producers, distributors and, finally, to consumers. In many cases, there is also a reverse channel where wastes, packages, and defective/obsolete products climb back the supply chain. In some cases (such as a defective product), distributors will take back the merchandises, but in many others, a specialized segment of the distribution industry aims at collecting and then recycling goods and parts. Thus, reverse logistics (or reverse distribution) is concerned about the movements of previously shipped goods from customers back to manufacturers or distribution centers due to repairs, recycling or returns.

Examples of situations of reverse channel of distribution

- Return of products to be recycled (bottles, paper etc.)

- Return of products customers order online

- Return of product under warranty

- Return of unsafe products

- Return of wrong order

Drop shipping is a supply chain management technique in which the retailer does not keep goods in stock, but instead transfers customer orders and shipment details to either the manufacturer or a wholesaler, who then ships the goods directly to the customer.

Physical Distribution Management System

Physical distribution management system is concerned with ensuring the product is in the right place at the right time. When a distribution channel or a network of intermediaries is organized, several decisions are undertaken for the smooth management of goods as they move from the producer to the consumer. Each channel member in the distribution system must be carefully selected and the company must decide the type of relationship it seeks with each of its intermediate associates. Once a network is established, the organization must then consider the procedure of transferring the goods efficiently in the physical sense i.e., it involves transformation from the place of manufacture to the place of consumption.

The cost and customer satisfaction can be optimized using business logistical techniques to the Physical Distribution Management system. The cost/service balance is a basic problem that physical distribution managers faces like there is no point cutting the cost of distribution if in the long run, sales are lost because of customer dissatisfaction or providing a level of service that leads to erosion of profits and are not required by the customer.

The increasingly demanding nature of the business environment has led to the growth of Physical Distribution Management system. The companies used to hold large inventories of raw materials and components initially. But nowadays, stock levels are kept to a minimum possible although industries and individual firms differ widely in their stockholding policies. It is believed that holding huge amount of stock leads to wastage of the potential working capital as it is not making money for the company.

Components of Physical Distribution Management system

There are primarily four components of PDM system, namely

- Order processing: The efficiency of order processing has a direct impact on lead times i.e., the time taken to reach the destination. Orders are received from the sales team that is processed through the sales department. The companies tend to set up regular supply routes that remain relatively stable over a period of time ensuring that the supplier performs satisfactorily. Often contracts are drawn and repeat orders are made at regular intervals during the contract period.

- Partnership Sourcing: This is an agreement between the buyer and seller to supply a particular product or commodity as and when required without the necessity of negotiating a new contract every time an order is placed. Order-processing systems should function rapidly and accurately such that other departments in the organization are informed immediately that an order has been placed and consequently the customer must be confirmed about the order’s receipt and the precise delivery time. Even before products are manufactured and sold the level of office efficiency is a major contributor to a company’s image. An unrecognized source of discrepancy between buyers and sellers is the incorrect ‘paperwork’ and slow reactions by the sales office. For efficient order processing the stock levels and delivery schedules should be automatically updated so that the management can rapidly obtain an accurate analysis of the sales position. There are various procedures designed to shorten the order processing cycle and simultaneously maintain the accuracy quotient.

- Inventory: Since stock levels have a direct effect on levels of service and customer satisfaction it plays a key role in the physical distribution system. The type of market in which the company operates determines the optimum stock level required to be maintained. In case stock-outs happen frequently then market share will be lost to more efficient and competent competitors, therefore the firm must ascertain the re-order point. Holding stock at levels below the re-order point might lead to a stock-out, whereas too high stock levels cause unnecessary expenses. Stocks of inventory represent opportunity costs that occur because the company engages its capital in holding stocks due to limited resources and intense competition. Thus If a company intend to hold high level of stock then it should be justified by a profit contribution that will exceed the additional stock carrying costs.

- Warehousing: Various companies enable dispatching of goods directly to customers function from their own on-site warehouses. It becomes more logical to locate warehouses strategically around the country in case a firm markets goods that are ordered regularly, but in small quantities. Transportation can be carried out in bulk from the place of manufacture to respective warehouses where stocks wait ready for further distribution to the customers. This system is used by large retail chains, except that the warehouses and transportation are owned and operated for them by logistics experts. An optimum strategy must be established that reflects the desired level of service which will of course increase when number of warehouse locations increases such that the cost will increase accordingly.

- Transportation: Transportation refers to the cost of bulk material distribution that is generally easy to calculate as it is directly related to numbers of units or weight. Costs associated with the mode of transport selected amongst alternatives must be controlled and constantly reviewed. Usually when the volume of goods being transported reaches a certain level some companies purchase their own vehicles, rather than using the services of haulage contractors. It must be noted that the chosen transportation mode must protect the goods effectively from damage in transit. Damaged goods not only affect profits, but also frequent claims increase insurance premiums and causes inconvenience to customers. This jeopardizes future business activities and transactions.