With the purchase requisitions and specifications as inputs from the departments and sections of the organizations, the restraints from the external environment and the factors about the demand pattern, the purchasing department has to make several decisions. Some are purely operational while some relate to policy formulation having far-reaching impact on the long-term success of the organization. In this section we shall discuss the operational decisions. Policy related decisions will be covered in later sections.

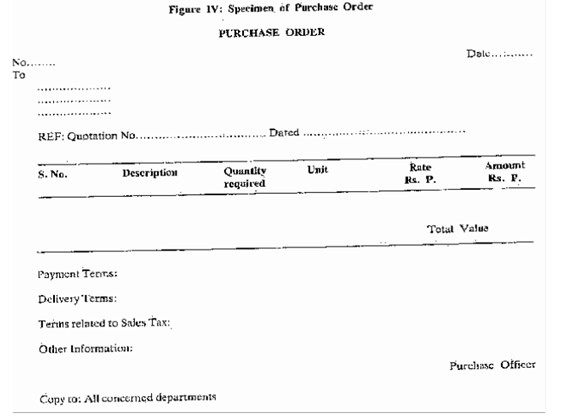

From purchase requisitions, the purchasing department generates purchase orders which are a legal document. Purchase order forms vary in their format and their routing through the organization. A purchase order should contain at least the following:

- Purchase order number (for identification).

- Date of issue.

- Name and address of supplier receiving the order

- Quantity and description of item(s)

- Required delivery date

- Shipping instructions

- Price and payment terms

- Other conditions governing the order

A sample of the purchase order is shown in Figure IV

We shall now discuss some of the decision function leading to preparation of the purchase order.

Supplier Selection

Information on external sources of supply can be obtained from numerous references: (a) industrial advertisements of the supplier appearing in newspapers and periodicals, (b) supplier catalogues, (c) supplier salesmen, (d) trade journals, (e) yellow pages of telephone directory, (f) trade directories prepared by government agencies and trade associations, (g) list of suppliers approved by the government agencies, (h) enquiries through advertisements or individual communications, and (i) records of the organizations past purchases.

After compiling the information about suppliers for the needed item, relative proficiency of each potential supplier must be assessed on the basis of comparative quotations of price, quality, quantity, delivery, and other services. Other relevant variables are the supplier’s management capability, technical ability, production capacity, depth of service, and financial stability. The purchase order is then issued to the most promising supplier. The information about other suppliers can be stored for future references.

Timing of Purchases

An organization is primarily interested in an adequate supply of material at the best price consistent with quality requirements. Timing is not a critical concern when the purchases are made in price stable market but it becomes critical in unstable price market situation. Following approaches may be adopted while trying to time the purchases in response to market conditions:

Speculative Buying: It involves purchasing in excess of foreseeable requirements in order to make profit (or imputed profit) from rising prices. Opportunities arise for such a purchase when price falls temporarily and the organization has sufficient working capital to finance such speculative purchases.

Forward Buying: It involves purchasing in economical quantities exceeding current requirements, but not beyond actual, foreseeable requirements. This approach is often used when prices are stable over time. It is adopted to obtain a favorable price, to get quantity discounts, to secure items when they are available, and to protect against prospective shortages. It, however, assumes the risk of increased inventory holding cost which ties up working capital.

Hand to mouth Buying: This practice is resorted to satisfy only immediate current requirements and may be uneconomical. This may be suitable in case of high-value items. It is not recommended for normal operations.

There are inherent risks in all these approaches in the environment of fluctuating market and price instability. Two techniques may be used to reduce the financial risk.

Time budgeting Purchases: Using time-budgeting purchases, an organization can frequently purchase an item over a long periodic cyclic fluctuation at an average price very close to average market price. This is accomplished by purchasing small quantities over short operating periods of equal length.

Hedging: The organization purchases the required quantity on the spot or open market and at the same time sells the same quantity in the future market contracting to deliver at a future date in order to mitigate the risk associated with fluctuating prices. This approach, however, can be used in case of those items for which organized commodity markets or exchanges exist.

Price Determination

Price per unit of an item comprises the unit purchase price, transportation cost, handling cost, inspection, insurance and the administrative variable cost. The right price simply means the lowest possible total price for the organization.

The typical approaches for price determination are published price lists, competitive bidding, and negotiation. Price lists published by the suppliers give initial indication of the price. In competitive bidding, the requests for bids are sent to several suppliers. Usually the lowest bidder gets the order. Normal practice requires at least three competitive quotations wherever possible. Generally competitive bidding is most applicable to standardized products that are widely used and are produced to stock. Bids are normally secured when the size of an order exceeds some minimum amount.

Negotiation is the approach resorted to when time is too short, the number of bidders is too small, value of purchase is high, willingness to compete is lacking, or the specifications are too vague. In such circumstances, the buyer contacts the potential supplier and negotiates for the fair price and prompt delivery. An advance planning and analysis are expected to bring satisfactory results out of negotiation.

While determining the price, shipping terms should also be clarified. The shipping terms established (1) who will pay the freight charges, (2) when does the buyer takes the legal title to the goods, and (3) who will prosecute loss and damage claims against carriers. There are numerous terms of shipment, but the most common ones are:

F.O.B. (Free on Board) Buyer’s Plant: The buyer takes the title to the goods when the goods are delivered at his plant and supplier pays all transportation charges and processes all claims against the carrier for damages or loss of goods.

F.O.B. Seller’s Plant: The buyer takes the title when goods are loaded onto the carrier and he pays all transportation charges as well as negotiates all freight damage claims with the carrier.

F.O.B. Seller’s Plant-Freight Allowed: Legal responsibilities same as in F.O.B. seller’s plant, but the supplier pays the freight charges.

C.I.F. Contracts: The price includes cost of materials, insurance and freight.

F.A.S. (Free Alongside Ship): Used in shipping by sea where supplier is responsible for getting goods to the ship, and the buyer takes title as well as all responsibilities thereafter.

Further, purchase contracts can be of fixed price (quite common), cost plus contract (no definite limit to costs) or blanket order (for six months or one year) type.

Discounts: An important aspect of price determination involves discounts that can be secured. Following types of discounts are common:

- Trade Discount: To protect certain distribution channel when it is economical to Purchase System and Procedure buy from the distributor than the manufacturer,

- Quantity Discount: For purchasing worth beyond certain amount of money.

- Seasonal Discount: For purchasing in off-season.

- Cash Discount: For prompt and full payment.

Quality and Quantity

The process of determining right quality in purchasing implies striking a balance between technical specifications and economic considerations. The right quality has no absolute meaning but is specified in relation to a purpose. As mentioned above most of the technical specifications are decided by the requisitioning department. The purchasing department should be instrumental in making the quality decisions by making, to the requisitioning departments, available various market grades, trade names, commercial standards etc. and corresponding prices and sources of supply to enable them to specify quality of items. Once the quality standards are specified, the purchasing department makes arrangement in collaboration with the requisitioning department for the inspection of the items after delivery. Sometimes, inspection is performed by an organizational representative in the vendor’s plant. On-site inspection can save time and money while minimizing operational delays from the inferior quality. For normal items supplied in lots, inspection for acceptance is carried out by sampling.

Procedures should be established for handling inferior quality. Should the shipment be returned to the supplier and contract cancelled? Should the buyer rework the item to an acceptable quality and bill the supplier? Should only rejected items he returned for replacement and acceptable items retained? Such issues must be resolved in advance to maintain a long-term relationship.

After determining the quality, the next important step is to determine how much quantity to buy and when. For items continuously used, the purchasing department can collect the projected demands from various departments and then can incorporate these details into the blanket purchase order. For large single orders, there is not much to decide about the quantity. Small-value purchases are made as and when need arises. For normal purchases usually two quantities govern the ordering decision: reorder-point an order quantity. When the stock goes to or below reorder-point an order for quantity equal to order quantity is placed.

Reorder-point = Safety stock + average demand during the lead-time

Order quantity =

Where

A = fixed cost of ordering (Rs. /order) D = average annual demand (unit/year)

h = holding cost (Rs./unit/year)

Safety stock depends on the variation of demand and can be taken as 3 times the standard deviation.

In case of production components, the determination of right quantity can he linked with the concept of Materials Requirement Planning (MRP).