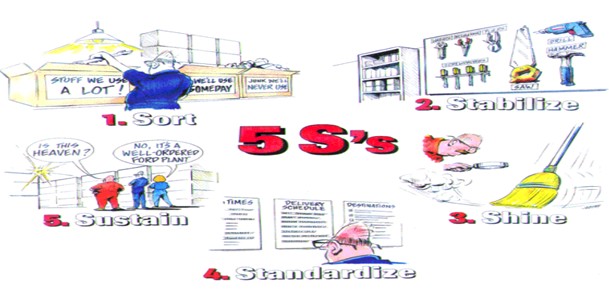

5S are the principles of work environment improvement. Companies usually initiate with 5S, for their lean manufacturing program. Five S is a manageable process which people easily grasp and adapt to it. This technique focuses on standardized cleanup of the workplace but, involves much more than that.

Five S is a method to organize and manage the workspace and work flow for improving efficiency by eliminating waste, improving work flow and reducing process inefficiencies. Five S is a reference to five Japanese words that have been translated into English. The 5S’s are, Sort (Seiri), Straighten (Seiton), Sweep (Seiso), Standardize (Seiketsu) and Sustain (Shitsuke).

Cleanliness and order are important issues in a manufacturing or processing environment. The core idea is to increase productivity, improve the level of quality and raise work ethic which is reached when the working environment is clean and in good order. 5S is a practical tool for maintaining these as, it helps to find and eliminate issues in time. The 5S-model is flexible as it can be applied in to an office as well as in the production environment of a company for developing systematic and disciplined operations.

The employee’s workstation is an important part in the employees’ daily life which should be clean, in good order and safe. 5S also focuses on making it an efficient and comfortable as well. Employees must be at ease to simplify processes resulting in fewer accidents, low rejection or discards, waste running, stoppages and mistakes. The various stages are discussed as

Phase 1 – Sort (Seiri)

The first phase is called Sort and it focuses on to sort everything. Every tool, object and instrument is noted and their demands are evaluated. This phase also includes a task of criteria creation which, differentiate amongst useful and useless products. Removable products are sorted and disposed later on. Useful products are sorted and places are created for them after sorting.

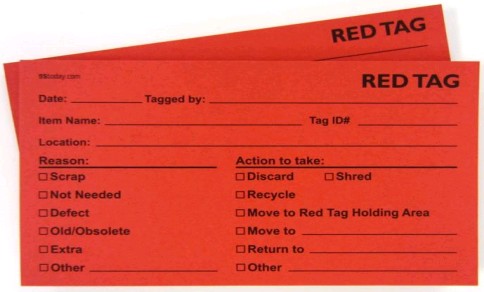

Most used method in sorting is the “Red-tag”-program in which the removable products are marked with a red tag as in the figure below. The tag has information on name of the inspector, date, demand, reason of the tag, storage place and disposition date. Jigs, moulds, junk and work-in process items are used stored all over the workplace and this phase gets rid of all these by moving the tagged products into red tag-area and after that, either positioned again or disposed off.

Removing useless items clears working environment and adds more space to act. This phase also helps to keep places clean and in good order. Moving and safety at work gets better by saving and increasing space and clarifying processes. The sorting should be conducted on a daily, weekly and monthly manner depending upon the requirement. The idea is to ensure that everything left in the workplace is related to work and even necessary items are absolute minimum.

Phase 2 – Set in Order (Seiton)

This phase finds storage space for every needed tool or instrument and the spaces are properly marked. The organization of the storage space is in a way so that those can be found easily when needed. Setting in order also ensures finding the item by anyone else also easy and placing back at marked space. This marking remove useless searching, improves safety at work and make working environment better. Tools and wires are also marked or color coded for easy access and usage. Marking off the floor and dividing it into stations is also undertaken to make passages and simplify movements in the production areas. When pulling the lines, it is useful to mark places for pallets, pallet jacks and garbage cans at the same time. Color-codes and signs are used to prevent equipments getting mixed-up.

Time used into taking something to its own place or getting it, is pointless when thinking from works point of view. Because of that, pointing places is critical. Belongings needed rarely are moved beyond and equipments needed daily are staying near the stations. If everyone has quick access to an item or materials, work flow becomes efficient, and the worker becomes productive. The correct place, position, or holder for every tool, item, or material must be chosen carefully in relation to how the work will be performed and who will use them.

Phase 3 – Shine (Seiso)

The first and second phase address issues related to space but dirt which is present everywhere, is addressed by the third phase. Dirt wear down machines and makes quality worse. Seiso focuses on cleaning up everything. Floors, tools, tool racks, devices and especially machines are cleaned of dirt. Machinery life increases and everything is ready in top condition for use when needed. This results in user maintenance and making it easier to identify possible errors and deviations. Seiso consists of cleaning up the workplace and giving it a ‘shine’. Everyone should see the ‘workplace’ through the eyes of a visitor – always thinking if it is clean enough to make a good impression.

Clean environment creates optimal working environment as, everybody watches out mistakes and from the other hand, even the smallest mistakes are easier to register. Oily and dirty floors can cause slips and objects in wrong places can be fatal which are addressed in this phase. Cleanliness manual or instructions should be created for maintaining it.

Phase 4 – Standardize (Seiketsu)

Without daily discipline and clear follow-up and operation routines it is too easy to return into old habits and fall back to inefficiencies. This phase centers on standardization by emphasizing creation of procedures and routines. The purpose of this phase is to use and maintain what was achieved in earlier three phases (sorting, stabilizing and shining ) into continuous and developing course of actions. By creating the methods into standards, employees are expected to obey them. Mundane tasks are established and are followed precisely. Instructions should be clear and easy to understand so that anyone could check the workstation with the help of those.

It consists of defining the standards by which personnel must measure and maintain ‘cleanliness’. Seiketsu encompasses both personal and environmental cleanliness and starts with personal tidiness. Visual management is an important ingredient of seiketsu. Color-coding and standardized coloration of surroundings are used for easier visual identification of anomalies in the surroundings. Check lists are created in standardization phase which also helps in monitoring of the level of operation model.

Phase 5 – Sustain (Shitsuke)

Shitsuke, means ‘Discipline’ and denotes commitment to maintain orderliness and to practice the first 4S as a way of life. The emphasis of shitsuke is elimination of bad habits and constant practice of good ones. Once true shitsuke is achieved, personnel voluntarily observe cleanliness and orderliness at all times, without having to be reminded. Sustaining the progress as in this phase, enables method becoming a part of daily actions and development. Creating competition amongst departments can also motivate the employees and as well as help in sustenance.

Internal audit lists are created in this phase and conducted at regular intervals. The results of audits are gathered and put on to bulletin boards so that everyone can see and follow up the development of 5S-actions. Evaluation should include implemented changes and comparison to earlier months. Audit is essential tool in progress of pushing cleanliness and sustaining a creditable level of order.