Material Handling in Supply Chain Management

Material Handling in Supply Chain Management is the main activity of every manufacturing organisation. It is approximated that nearly 15 to 25% of the cost of the product is attributable to material handling activities and as such it warrants consideration in every branch of manufacturing operation i.e. setting up the factory, planning the facilities, selecting the manufacturing methods, mechanisation, purchasing, receiving and storage, inspection, warehousing and distribution of the final product.

Material Handling Principles in Supply Chain Management

Material handling principles are grouped into five categories –

- Planning Principles

- Operating Principles

- Equipment Principles

- Costing Principles

- General Principles

Product Availability

The level of product availability is a very important component of the supply chain’s responsiveness towards its customers. The level of product availability can be calculated using the cycle service levels and the fill rate and is also called the ‘customer service level’. The higher the customer service level, the better responsiveness a firm can provide to attract customers. With the help of higher customer service levels, a firm can increase its revenue by increasing its sales.

In order to have optimal levels of product availability a firm needs to strike the right balance between the level of inventories held and the cost of holding these inventories. Thus, with the help of optimal levels of product availability, a firm can maximise its overall profitability.

Improving Supply Chain Profitability

Now that we are clear with the factors affecting the optimal level of product availability, let us concentrate on how the chain manager can improve the supply chain profitability by taking certain actions. The two most important areas of concern in a supply chain to increase the overall profitability are:

- Increase the salvage value of each unit, which in turn increases the overall profitability of the firm.

- Decrease the margin lost due to stock-outs, thereby increasing the overall profitability.

Optimal Cycle Service Level

It is defined as a function of the ratio of the cost of overstocking and cost of understocking. One of the measure that a supply chain manager can use in order to maximise profitability is the reduction of demand uncertainty. With reduced uncertainty, he can better match the supply and demand by reducing both overstocking and understocking. The following strategies can be applied to reduce demand uncertainty –

- Efficient forecasting

- Quick response

- Postponement

- Tailored sourcing

Retails Supply Chain Management

Retail SCM offers efficient, cost-effective and flexible supply chain solutions and services to retailers around the world. The customers benefit from proven expertise and a range of solutions that address key business issues such as on-shelf availability, supply chain agility, effective use of infrastructure and global sourcing.

Retail SCM provides focused solutions for retailers seeking to –

- Increase customer satisfaction through better matching of supply and demand

- Maximize the potential benefits from global sourcing

- Optimise their supply chain and release capital to be invested closer to the customer

- Expand through entering new markets and accessing new channels to market

Distribution to Stores Management

In Retail SCM, distribution to store solutions are focused on helping retailers create efficient and flexible supply chains to deliver product to retail outlets at high levels of service. Retail SCM seeks to help customers –

- Design, structure (or re-structure) their distribution networks to achieve required service levels at minimum cost

- Increase capacity and throughput of existing warehouse platforms

- Increase productivity and quality from warehouse and transport operations

- Deliver products in a store friendly format to create efficient operations in-store

Distribution Channel

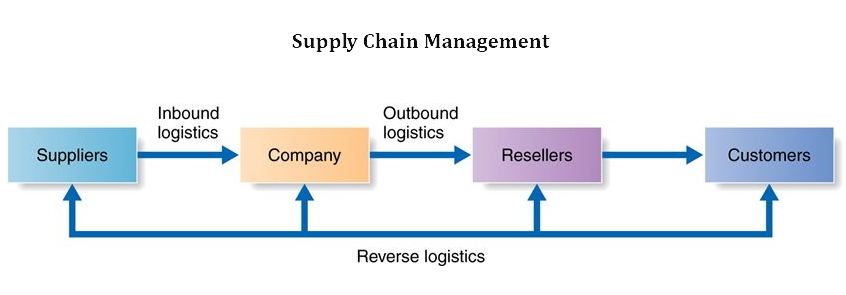

Frequently there may be a chain of intermediaries, each passing the product down the chain to the next organisation, before it finally reaches the consumer or end-user. This process is known as the ‘distribution chain’ or the ‘channel.’ Each of the elements in these chains will have their own specific needs, which the producer must take into account, along with those of the all-important end-user.

A number of alternate ‘channels’ of distribution may be available –

- Selling direct, such as via mail order, Internet and telephone sales

- Agent, who typically sells direct on behalf of the producer

- Distributor (also called wholesaler), who sells to retailers

- Retailer (also called dealer), who sells to end customers

Channel members

Distribution channels can thus have a number of levels. Kotler defined the simplest level, that of direct contact with no intermediaries involved, as the channel.

The next level, the ‘one-Zero/’ channel, features just one intermediary; in consumer goods a retailer, for industrial goods a distributor, say. In small markets (such as small countries) it is practical to reach the whole market using just one and zero-level channels.

In large markets (such as larger countries) a second level, a wholesaler for example, is now mainly used to extend distribution to the large number of small, neighbourhood retailers.

Channel management

The channel decision is very important. In theory at least, there is a form of trade-off; the cost of using intermediaries to achieve wider distribution is supposedly lower. Indeed, most consumer goods manufacturers could never justify the cost of selling direct to their consumers, except by mail order. In practice, if the producer is large enough, the use of intermediaries (particularly at the agent and wholesaler level) can sometimes cost more than going direct. The channel decision is very important. In theory at least, there is a form of trade-off; the cost of using intermediaries to achieve wider distribution is supposedly lower.

Vertical marketing

This relatively recent development integrates the channel with the original supplier – producer, wholesalers and retailers working in one unified system. This may arise because one member of the chain owns the other elements (often called ‘corporate systems integration’); a supplier owning its own retail outlets, this being ‘forward’ integration. It is perhaps more likely that a retailer will own its own suppliers, this being ‘backward’ integration

The intention of vertical marketing is to give all those involved (and particularly the supplier at one end, and the retailer at the other) ‘control’ over the distribution chain. This removes one set of variables from the marketing equations.

Horizontal marketing

A rather less frequent example of new approaches to channels is where two or more noncompeting organisations agree on a joint venture – a joint marketing operation – because it is beyond the capacity of each individual organisation alone. In general, this is less likely to revolve around marketing synergy.

Distribution – Channel Strategy

Factors that influence the choice of distribution channel by a business –

Market factors

- Buyer Behavior

- Buyer Need

- Markup/commission

Producer Factors

- Resources to perform functions

- Customer Based Distribution Skills

- Producers Control over price