Role of Inbound Supply Chain Management

Inbound Supply Chain Management can be defined as the process by which companies acquire raw materia!, parts, components, different products and services from various suppliers in order to carry out their operations. Such a process is also called as procurement.

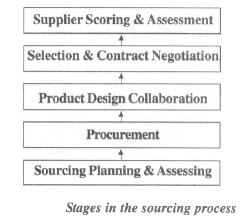

- Supplier scoring and assessment means rating the supplier’s performance.

- Supplier contract need to be formulated and negotiated with the suppliers. Here it is important to keep in mind that the primary objective of the supply chain is to maximise profitability and also benefit both the contracting parties

- While performing Product design collaboration it is important to ensure that these designs are communicated effectively to all the parties involved in the production and operation departments.

- In Procurement design stage the supplier sends the products in response to the orders placed and delivered on schedule at the lowest possible costs.

- Source planning and assessing involves the identification of opportunities where the buyers are able to decrease the overall cost of the product.

Supplier Scoring and Assessment

Large number of firms make the mistake of focusing on the prices quoted by the suppliers, ignoring various other factors that affect the total cost of the supplier. It is very important that buyers or sourcing agents take note of the following characteristics of the supplier. Factors to be considered at the time of supplier scoring and assessment having a a great impact on the total supply chain cost –

- Replenishment lead time

- Scheduled performance

- Supply flexibility

- Delivery frequency

- Supply quality

- Transportation costs

- Pricing

- Coordination of information

- Product design capability

- Exchange rates, taxes and duties

- Supplier viability

Supplier Selection

Selection of suppliers is the next stage in the inbound SCM process. Once the supplier scoring and assessment is over, and all the relevant information is available, it is time for supplier selection. The firm needs to decide whether it will use single sourcing or will have multiple suppliers from which to source the product. Once the firm is able to decide this, contracts need to be structured between the buyer and every supplier.

Contracts

Contracts between the suppliers and the buyer are made keeping in mind two basic aspects of supply chain profits and product availability. There are three types of basic contracts that are best suited to both the suppliers and the buyers:

- Buyback or return contracts – Buyback contract is one that allows the retailer to return the unsold goods upto a certain specified amount at an agreed price.

- Revenue sharing contracts – Buyer pays only a minimal amount for each unit purchased from the supplier, but shares a fraction of the revenue for each unit sold.

- Quantity Flexibility contracts – buyer is allowed to modify the order within certain limits as notified by the supplier as and when the demand visibility inches closer to the point of sale.

- Contracts for supply chain costs co-ordination – In order to keep a check and control over the supply chain costs, the supplier and buyer can enter into a quantity discount contract. Under a quantity discount contract, there is a reduction in the overall costs but leads to higher lot sizes, and thus, higher levels of inventory in the supply chain. It is typically suited for commodity products, where the supplier has high fixed costs per lot.

Increase in agent effort contracts

There are two basic types of contracts aimed at increasing agent effort with an aim to increase supply chain profitability and high level of product availability. These two types of contracts are:

- Two part tariff contracts – It offer the right incentives for the dealer to exert the right amount of effort.

- Threshold contracts – It offer the dealer an increase in the margin for sales exceeding a certain threshold (limit).

Performance improvement contracts – Performance improvement contracts are structured at instances where a buyer wants performance improvement from a supplier who has little incentive to do so. In this case, a shared savings contract is formulated between the buyer who is given sufficient power, and the supplier. The shared savings contract can be used to induce the performance improvement from a supplier along various dimensions like lead time, where the benefit of improvement accrues primarily to the buyer, whereas the effort for improvement comes primarily from the supplier.

Procurement

Once the suppliers are selected, contracts signed and products designed, the buyers and suppliers now begin the next stage of the procurement process together. The procurement process begins with the buyer placing the order and ends with the buyer receiving the order and making payments for the products received. It is very important to keep in mind which goods are to be procured first, whether they are direct material or indirect material.

If linked with production, the procurement process for direct material should be designed to ensure that components are available at the right place, in the right quantity and at the right time. If we focus on the procurement of indirect material, then the focus is on numerous, low value transactions. The procurement process for indirect material should focus on reducing the transaction cost of each order, which tends to be high because of the difficulty in selecting goods, getting approvals and delivering a purchase order.

Another important requirement for the procurement process, for both direct and indirect material, is to be able to aggregate orders by product and supplier. This is because the consolidation of orders improves the economies of scale at the supplier’s end and also during transportation. It also allows the firm to gain from quantity discounts that may be offered by the supplier.

Inbound Supply Chain Management Planning and Analyzing

In order to make future sourcing decisions, each firm must analyse its procurement spending and supplier performance. It is important to aggregate the spending across and within categories and suppliers. Aggregation provides visibility of what a company is purchasing and from whom. Secondly, supplier performance should be measured against a plan on all dimensions that impact total costs such as response, lead times, quality, etc as discussed at the beginning of the unit.

Inbound Supply Chain Management in Practice

Below features make sourcing easier and efficient, resulting in lower product costs and increasing the overall profitability of the firm:

- Use of multi-functional teams

- Coordination across regions and business units

- Evaluation of total cost of ownership

- Building long term relationships with the suppliers

Inbound to Manufacturing

Inbound to manufacturing is referred to as complete end-to-end logistics management of inventories, facilities and labour concerned with the inbound flow of materials from vendors and supplier origins to consumption points in manufacturers’ production lines. The service encompasses:

- Network, transportation and facility design

- Inventory optimisation

- Supplier management

- Transportation management

- In-plant services