Are you keen to know what exactly is this 5S? The answer is here- the 5S Method is a standardized process that when implemented properly creates and maintains an organized, clean, safe and efficient workplace. Basically, borrowed from the Japanese technique while, primarily it was popularized by Taiichi Ohno, the designer of Toyota Production System and Shigeo Shingo, who also put forward the concept of poka-yoke.

Implementing the 5S Methodology .i.e. The first steps Toward Workplace Efficiency

When a company/organization decides to start down the path of the continuous improvement culture this is when one of the first tools 5S that can be applied. Therefore, a 5S implementation helps to define the first rules to eradicate waste and maintain an efficient, safe, and clean work environment.

Quality tools and techniques

The 5S methodology is very simple for everyone to start using. As, it doesn’t require any technical analysis. And therefore, can be implemented globally in all types of companies/organizations, ranging from manufacturing plants to offices, small businesses to large multinational organizations. And in both private and public sectors. What makes it an engaging aid for the operators, directors and customers alike is Its simplicity, practical applicability, and visual nature.

Why Use the 5S Methodology?

When it comes to eliminating the waste 5S is the perfect tool to identify the first improvement projects in your company. Although, sometimes it’s viewed as a housekeeping technique. While it is actually an innovative management system that helps people think lean, paving the way for the adoption of Lean principles in the organization. And understanding the 5S methodology is one of the foundations of Six Sigma principles, and can be extremely beneficial for all kinds of organizations.

With this you’ll learn what the big deal about 5S is,

- how to formulate an action plan for 5S implementation, and

- how best to command this powerful tool for improved productivity, elimination of wasteful processes, and

- all-round development!

For more on harnessing the 5S at the workplace and personal productivity, here’s an insight that investigates ways to enhance performance using the 5S Methodology.

Step 1: How Well Is Your Business Doing?

So, before you get started, let’s perform a simple test. If your is answer yes to any of the following questions, then you may find 5S really useful and effective:

- Firstly, do people in your workplace struggle to locate documents or files, whether in physical or digital format?

- Secondly, are there loose, sagging electrical cables in the workplace?

- Next, are there files, drawers, and cabinets that are unlabeled, or do they contain unmarked content that is hard to identify?

- Subsequently, if valuable space taken up by useless items?

- Then are there papers in your workplace that are not used and are gathering dust?

- Also, does everybody know how to keep the workplace organized and are fully aware of their roles and responsibilities?

Now if you answered yes to any of these questions, then 5S may be exactly what you need!

Step 2: The 5S Methodology: Broken Down

What Does 5S Stand For?

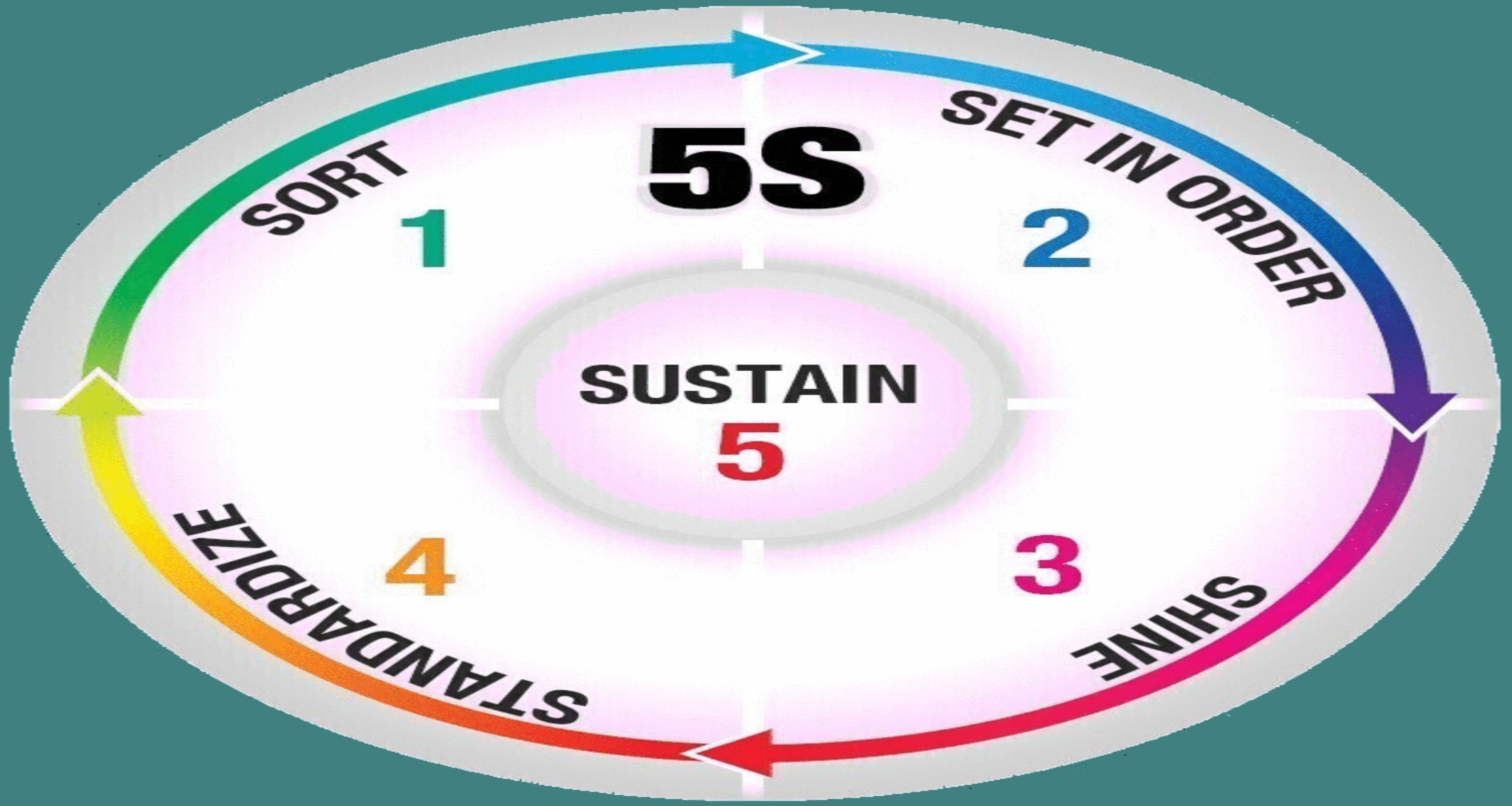

This name 5S refers to a set of five terms borrowed from Japanese. All beginning with the letter S when transliterated. The equivalent terms in English also begin with an S. In essence, these five terms represent the five steps toward operational and process excellence:

Steps to operational and process excellence

Sort–Seiri

Separate all the required and necessary tools, instructions, materials, from those that are of no use or not needed. Therefore, just get rid of everything that isn’t necessary from the work area.

Store- Seiton

Sort and organize all the required equipment, tools, data, material, files and resources for quick, easy location and the use. Finally label all the storage locations, equipment and tools.

Shine- Seiso

Set new standards for cleanliness. Like- clean and remove all trash, grease, and dirt. Make sure everything must be clean, tidy, and neatly put in its appropriate place. As cleanliness provides a safe workplace—and makes potential problems noticeable, e.g., equipment leaks, loose parts, missing guards, loose paperwork, or materials.

Standardize- Seiketsu

Engage your workforce to systematically perform and follow the steps 1, 2, and 3 listed above regularly, to maintain the workplace in perfect condition as a standard process. Also, establish schedules and set expectations for adherence.

Sustain- Shitsuke

Make the 5S part of your culture, and combine it in your corporate philosophy. To make 5S one of your organizational values, it is important to build organizational commitment. So that everyone develops 5S as a habit. Integrate the 5S methodology into the performance management system.

Step 3: The Action Plan

You can simply implement the 5s by training your staff to understand its system. And this may be followed up with only on-day session with every employee or the whole just to make sure they all are on the same page as far its implementation is concerned.

So, in that first one-day session, employees should look be ready to meet the first three 5S requirements:

- Initiate with taking a picture of the current status of your workplace.

- Then sort to separate anything that is needed and necessary from the unwanted.

- Subsequently organize the things you need. So that there is a place for everything and also everything has a place. And resultant you should be able to find anything in just a few seconds.

- Next clean the workplace and get rid of things that make it difficult to maintain cleanliness, such as boxes on the floor that prevent you from being able to clean the entire surface instantly label them and store them in labelled drawers, instead.

- Moreover, prepare an action plan for the items you aren’t able to deal with that day. But will be able to in the near future. And this could include selling items which you no longer use, you can donate them, recycling is a very good option, or throw them away.

- Now, take a second picture after the entire day’s work, for review.

“To learn and show to apply these principles then get a certification to show for it with a professional Certified 5S Professional”

Step 4: Standardize

Now during the second one-day session, i.e. two weeks later, the employees should take the third picture and compare it to the first two shots. There are many organizations who set up peer audits to check on how the 5S principles are being met as well as to ensure the plan is moving forward. Therefore, work together to define ways to standardize the improvements over time: define roles and responsibilities, organize cleaning schedules, and prepare written procedures or diagrams to help everyone remember what to do.

Step 5: Sustain

Then during the third one-day session, that’s again two months later, check to see how your workplace looks and schedule another peer review. So, this way, you can make sure the 5S are sustained by ensuring defined schedules are being met and everyone is following the procedures.

See- “Before and after of 5S implementation”

Who Should Participate in 5S?

So, if you’re wondering whether you should participate in the 5S, so the answer is very simple- If a department is starting 5S, managers and all other employees should be included. This is because if anyone is left out, then this could lead to confusion or messes that people don’t want to take ownership of.

There is a strong possibility that some/few people will play a vital role in 5S than others, which actually is fine. There might be 5S coordinators who are in charge of installing 5S labelling and its maintenance, keeping tracking of assigned tasks, or introducing new department members to the 5S system. These people will obviously spend a lot of time thinking about 5S compared to others. Everyone should think about 5S regularly, though. Initially 5S might take place as an event, but ideally it becomes a part of daily work for everyone.

Involvement of company leaders in 5S is vital, especially if 5S is a company-wide effort. Because when people see their superiors’ serious involvement in the 5S, then they are more likely to take it seriously too.

The Benefits it entails

Better time usage at work– This is because when we get rid of all the unwanted stuff and reorganize the important tools and supplies will eliminate clutter and confusion. Therefore, workers will spend less time in finding and retrieving what they need. Thus, can be more productive instead.

Less wasted space at work – When we eradicate all the unnecessary material stockpiles and reinforce tool storage will clear the room for some more useful applications. Since every square foot of floor space owns a cost, and thus getting the most out of that investment will maximize your facility’s profitability.

Reduced injury rates at work – When work area is organized for efficiency and ease of use resultant will reduce the movements needed for workers to do their jobs. Therefore, removing clutter and routinely cleaning up spills will eradicate trip hazards. As a result, workers will experience less fatigue and fewer injuries.

Reduced equipment downtime at work – When tools and equipment are kept clean, routinely inspected, and used in a standardized way, preventative maintenance is much easier, and major failures can often be prevented entirely.

Improved consistency and quality at work – With standardizing work processes variations and mistakes will be reduced. This is because eliminating the faults and failures, overall productivity can be dramatically improved.

Heightened employee morale at work – This is when 5S principles are used effectively, workers see that their input is valued, and their performance is recognized. Resultant this creates an environment where workers can feel pride in their work. Thus, take an interest in improving their company.

Therefore, these benefits are not just good sentiments. Because by documenting their situations before and after adopting 5S. There are many facilities which have been able to show actual, measured improvements.

Learning resources

Learning is the powerful weapon to gain the expertise and the required knowledge. There are many learning resources available for 5S Method just like any other concept. We have described a few of them here for you.

Blogs

The idea of reading is never outdated. Since we all know reading is the core of learning. There are many blogs available for those who want to learn the concepts of 5S. Look for the related and relevant logs covering the ideas and information on the 5S methodology. Read more and more to have a clear picture about the process.

Tutorials

There are piles of tutorials available for you to learn and understand the concept of 5S. Some are free while others are paid. Online sessions are also there basically these are teaching sessions helping the learner understand the concepts easily.

Certifications

These days certification courses are trending. They give you the complete knowledge and understanding of the 5S concepts. Moreover, the most important thing is to select the best and appropriate certification programme.

To Conclude:

The 5S is a simple process which can be implied anywhere be it workspace, personal space, etc. This is one of the most constructive technique which helps in binding the people at work. Thus, promoting and increasing the productivity.

Learn the concepts of 5S and become a Certified 5S Professional.