Process Capability Indices– In process improvement efforts, the process capability index (process capability ratio – PCR) is a statistical measure of process capability. It is the ability of a process to produce output within specification limits.

The concept only holds meaning for processes that are in a state of statistical control. Process capability indices measure how much “natural variation” a process experiences relative to its specification limits and allows different processes to be compared with respect to how well an organization controls them.

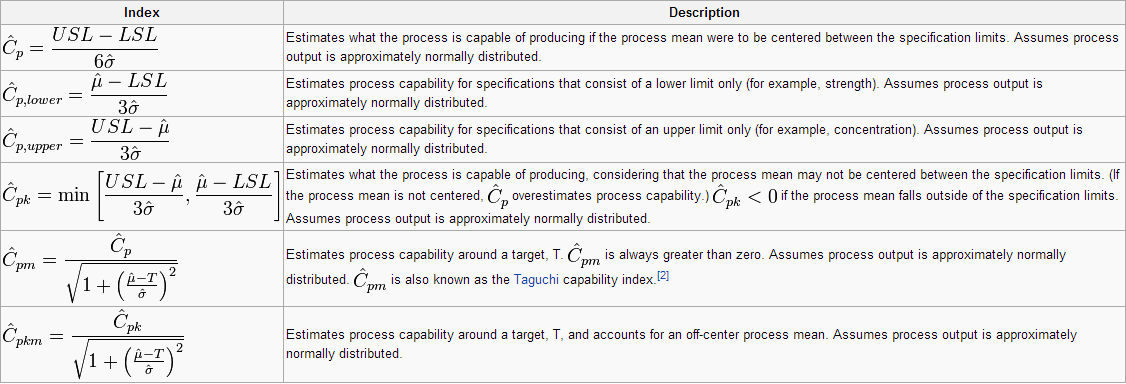

If the upper and lower specification limits of the process are USL and LSL:

- the target process mean is T,

- the estimated mean of the process is

and

and - the estimated variability of the process (expressed as a standard deviation) is

,

,

then commonly accepted process capability indices include:

Short-term and long-term capability

Short-term capability is measured over a very short time period since it focuses on the machine’s ability based on design and quality of construction. By focusing on one machine with one operator during one shift, it limits the influence of other outside long-term factors, including operator, environmental conditions such as temperature and humidity, machine wear and different material lots.

Thus, short-term capability can measure the machine’s ability to produce parts with a specific variability based on the customer’s requirements. Short-term capability uses a limited amount of data relative to a short time and the number of pieces produced to remove the effects of long-term components. If the machines are not capable of meeting the customer’s requirements, changes may have a limited impact on the machine’s ability to produce acceptable parts. Remember, though, that short-term capability only provides a snapshot of the situation. Since short-term data does not contain any special cause variation (such as that found in long-term data), the short-term capability is typically rated higher.

When a process capability is determined using one operator on one shift, with one piece of equipment, the process variation is relatively small. Control limits based on a short-term process evaluation are closer together than control limits based on the long-term process.

Test Your Six Sigma Black Belt Skills By Taking Our Practice Tests on This Link

Apply for Six Sigma Black Belt Certification Now!!

http://www.vskills.in/certification/Certified-Six-Sigma-Black-Belt-Professional